‘Circular Plastics Challenge’ Aims to Boost rPET Supply

Boise State University team named winner at NPE of contest supported by Net Impact, Coca-Cola, and Hillenbrand.

El Cerrito, Calif.-based nonprofit Net Impact partnered with Coca-Cola Co. and industrial giant Hillenbrand Inc to launch the Circular Plastics Challenge.

For this year’s second annual global challenge, they posed the question: “How might we increase the supply of rPET to create a more circular economy for plastics?”

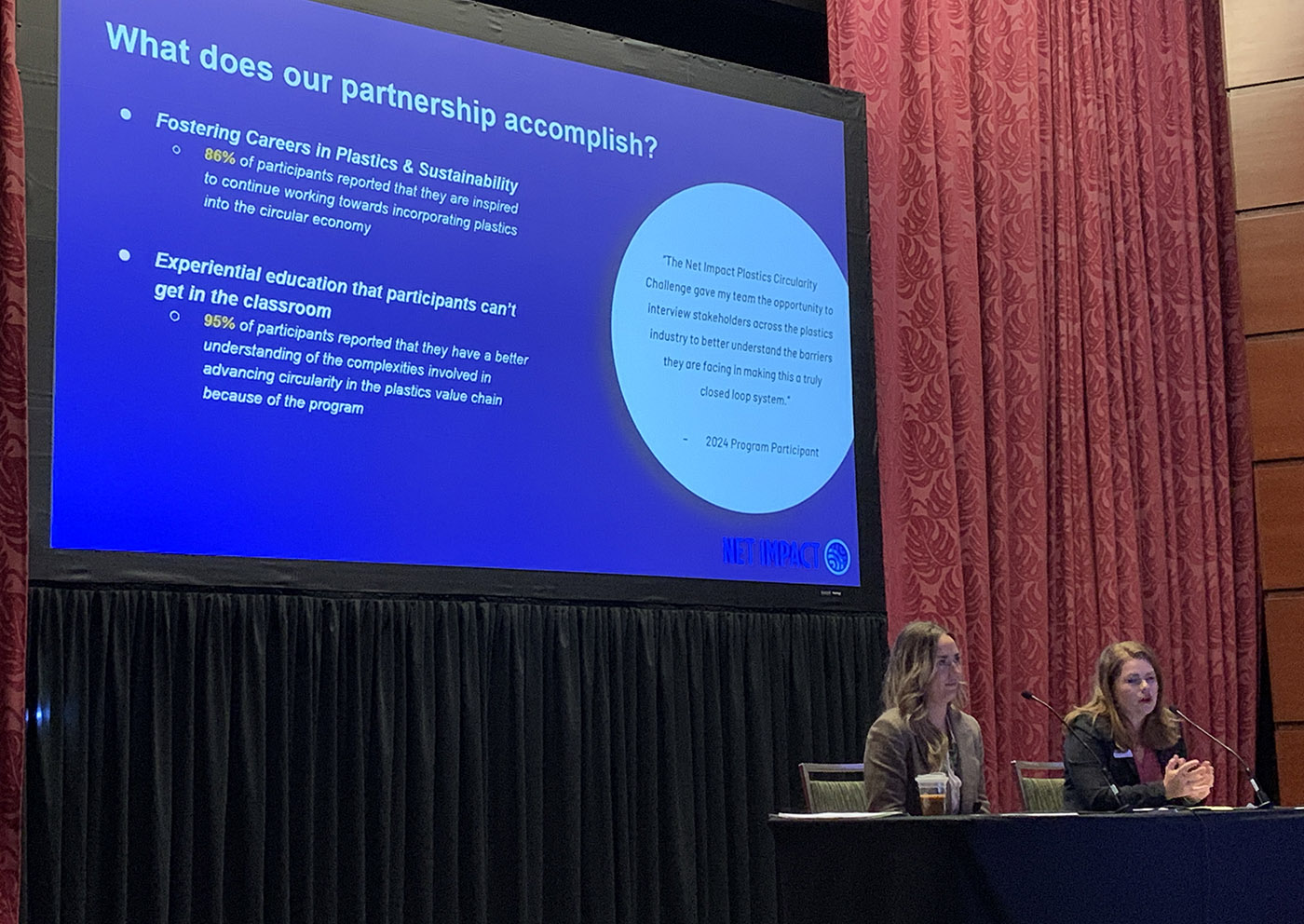

Manzo and Flynn also highlighted another desired outcome from their jointly sponsored challenge –– to foster careers in plastics and sustainability. Photo by Robert Grace

Makers of plastic bottles and containers are keen to increase their use of recycled PET, but the material can be in short supply. Plastic companies of all types want to mobilize the next generation of young leaders to embrace the industry and work together to enhance circularity.

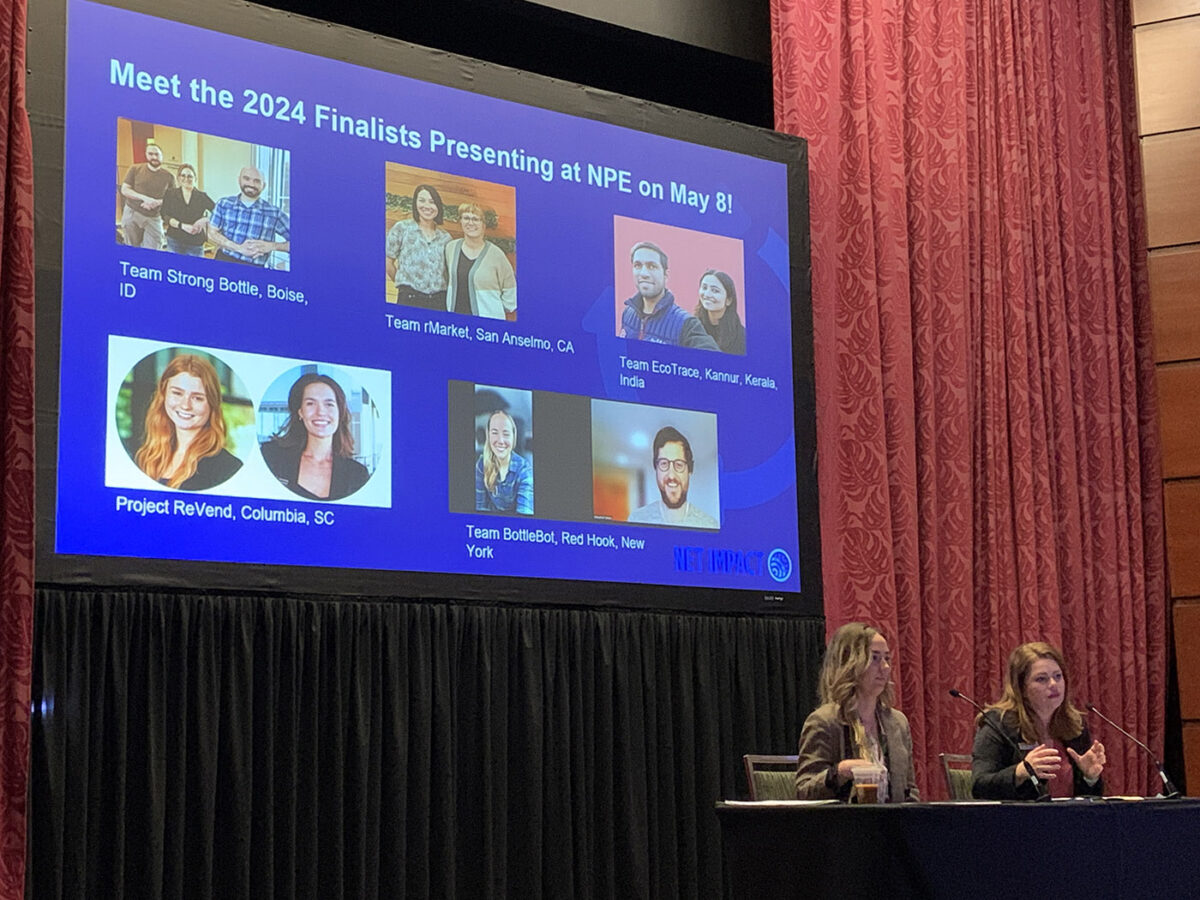

The 2024 challenge generated 65 applications from 18 countries. Participants formed teams of two to four people –– comprising undergraduate students, graduate students, and professionals worldwide. They had to submit their proposed solutions to the judges by March 29. The three partners selected five finalists. The teams presented their ideas during a virtual showcase on May 8 at NPE 2024 in Orlando.

And the Winner Is …

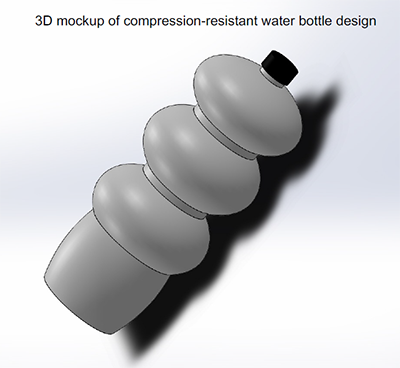

This rendering shows the winning Strong Bottle design proposed by the team from Boise State University in Idaho. By resisting flattening, up to 15 percent more PET can be recycled, the team asserts. Image courtesy of Net Impact and Hillenbrand

A team from Boise State University in Idaho earned the top prize of $10,000 for its proposed redesign of bottles called Strong Bottle. The new design (see rendering) aims to prevent flattening during recycling. During this process, the rPET bottle gets flattened by the pressurized air-sorting technology standard in materials recovery facilities. The team stated that doing so could result in a 15 percent increase in PET collected during the recycling process.

“The solution,” noted the judges, “addresses the problem that many lightweight PET bottles are landfilled because they are easily flattened and mistaken for paper during the recycling process in material recovery facilities.”

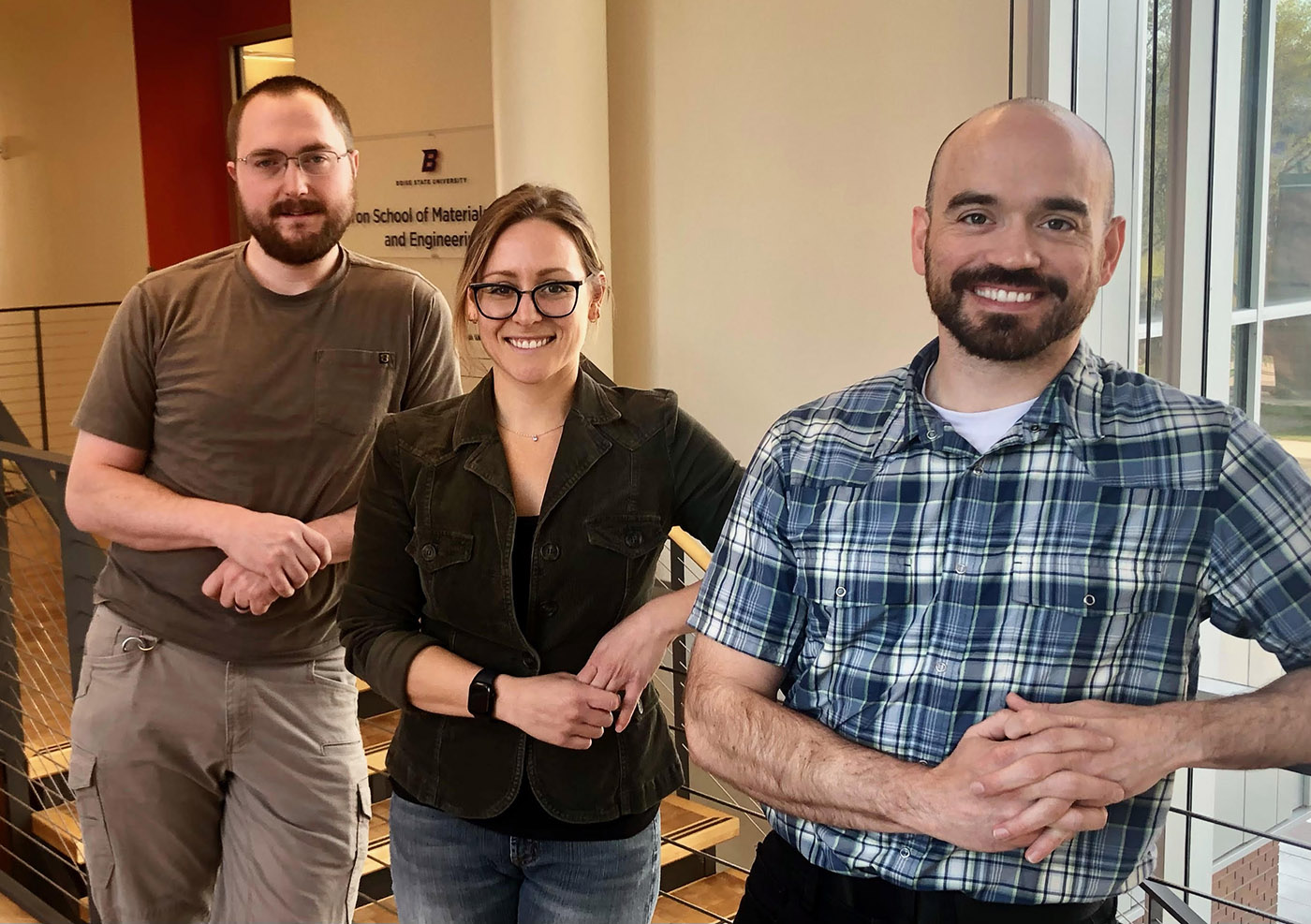

The Boise State team includes Terra Miller-Cassman, a materials scientist with a background in environmental science and consulting. In 2019, she pivoted her career to advance technologies and solutions to address plastic waste. She currently develops new recycling processes and sustainable materials as a Ph.D. candidate in materials science and engineering.

Team Strong Bottle from Boise State (L-R): Taylor Fackrell, Terra Miller-Cassman and Aaron Smith. Image courtesy of Net Impact and Hillenbrand

Taylor Fackrell and Aaron Smith, Ph.D., supported the Strong Bottle project through their engineering and design expertise. Fackrell is a systems assembly technician completing a bachelor’s degree in mechanical engineering. Smith is a professor in mechanical engineering with a background in product development.

A Team From India Takes Second Place

Second place went to EcoTrace, led by professionals Aadhithya Sujith and Sowmya Singh in Maharashtra, India. EcoTrace uses fluorescent-based markers in PET plastic manufacturing. They coupled that with Tracer-Based Sorting (TBS) technology to improve the material’s recyclability and downstream applications.

The team designed the zero-waste process. They aim to minimize tonnage loss, conserve valuable resources and reduce the carbon footprint associated with plastic production and recycling. They said that with an estimated 1 billion pounds of rPET recovery facilitated by TBS, the potential for mitigating plastic waste is substantial.

rMarket Program Nabs Third Place

The judges named rMarket as its third-place winner. That effort was led by Carissa Tasto and Jennifer Larkin. Both are recent MBA graduates from Presidio Graduate School in San Anselmo, Calif. They described rMarket as a full-service platform. It offers any retail chain the option of becoming a certified recycling center under the rMarket program while supporting logistics for reclaimers, processors, and copackers manufacturing rPET.

rMarket’s goal is to provide the equipment, marketplace, and industry expertise to transform a retail store into a centralized collection point for communities underserved by municipal recycling programs. At scale, it has the potential to provide enough material for 2.65 million soda bottles made with 30 percent rPET.

The second- and third-place teams took home $2,500 and $1,000, respectively.

Developing Tomorrow’s Plastics Workforce

Hilary Manzo, associate director of programs for Net Impact, spoke at a media event at NPE before the finalists’ presentations. She said that 86 percent of the students surveyed after they participated in the challenge said they would consider a career in plastics. And 95 percent said the project expanded their knowledge of the circular economy.

“This program,” said Net Impact CEO Karen Johns, “continues to strike a chord among our community of emerging business leaders. It allows them to grapple with a real-world corporate sustainability problem and put what they’re learning in the classroom to the test.

“Our partnership with Hillenbrand and the Coca-Cola Co. serves as a model for how businesses and nonprofits can partner together to activate emerging leaders, engage the next generation, and provide robust experiential education opportunities for a diverse future workforce.”