3D Printing of Mineral Foams from Recycled Industrial Waste for the Building Industry

With the growing demand for environmentally friendly activities and considering that 37% of global greenhouse gas emissions are currently generated by the construction sector, the implementation of sustainable construction has become a necessity.

Developing Mineral Foam 3D Printing

Among the challenges facing the construction sector are the reduction in the use of construction materials and the industrial waste generated during and after each project. Additionally, new architectural trends involving complex geometries are wasteful and difficult to manufacture using conventional methods. As a result, a doctoral student at ETH Zurich, in collaboration with FenX AG, developed a method for 3D printing lightweight insulation building components from cement-free mineral foams derived from recycled industrial waste. The project is called Airelements.

You can also read: 3D Printing Program Targets Rapid, High-Volume Production of Large Parts

Role of Foams in Construction

Foams are commonly used in the construction sector as insulation materials and play an important role in reducing the operational energy consumption of buildings. Furthermore, they are also used as temporary or stay-in-place functional formwork or as lightweight filling material.

Foam 3D Printing as a Solution for Complex Geometries

However, although foams are already used in the construction sector, their usage is often limited by the forms in which they are typically manufactured or because the on-site application of some foams requires a lot of work.

Taking this into account, the Airelements project developed a perfect match in foam 3D printing (F3DP). They take advantage of the benefits of foams (high strength-to-weight ratio, thermal resistance, and good machinability) and reduce waste generation during the production of geometrically complex formwork elements.

The development of the F3DP project required adapting a room with 3D printing robots in which they can print building elements in less than an hour and without the need for specialized tools for post-processing.

When the printed parts are ready, it is necessary that the elements harden for a week in a controlled environment at a temperature of 20-28°C and with a humidity of 20-70%.

Airelements Project

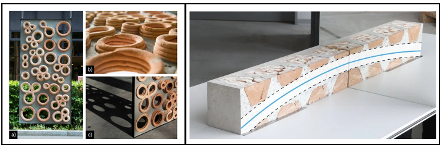

Prototypes of the first (left) and second (right) case of study of the project. More info can be found in Mineral composites: stay-in-place formwork for concrete using foam 3D printing.

The Airelements project has developed three case studies. The first corresponds to a lightweight facade panel where the foam acts as a stay-in-place formwork for the ultra-high-performance fiber-reinforced concrete (UHPFRC).

The second case is a floor structure based on a rigid funicular cover with ribs for changing load conditions. The last case study corresponds to the official product of the project: a monolithic corner column two meters high made of four 3D-printed segments. The four elements were glued with mortar and then sprayed with a white cement-free render.

Overall, F3DP is a technology that is still in development and promises to significantly reduce CO2 emissions.

Nevertheless, the Airelements project has developed great advances in this type of technology by reducing both the material consumption and the percentage of industrial waste without compromising the performance of the buildings.