AVs and EVs Propel Growth of Automotive Robotics

Precise and efficient manufacturing of autonomous and electric vehicles bode well for demand

The value of the automotive robotics market will increase at a compound annual growth rate of 8 percent from 2023 to 2030, according to consultant ReportLinker, of Lyon, France. This will put the value of the market at almost $23.2 billion by the end of the forecast period compared with $12.2 billion projected for this year.

In a study titled “Automotive Robotics by Type, by Component and by Application—Global Opportunity Analysis and Industry Forecast, 2023-2030,” ReportLinker (which has a U.S. contact telephone number) states that demand for “self-driving cars is fueling … automotive robotics market growth,” due to the “need for advanced technologies and systems to support their operations. Robotics is essential in ensuring precise control, efficient manufacturing and improved safety features for autonomous vehicles.”

Wide deployment of autonomous vehicles (AVs), either by business and government or consumers, is still some years away, of course, with many experts forecasting at least another decade or so before they are commercially available.

EVs Are Special Platforms That Need High-Tech Assembly

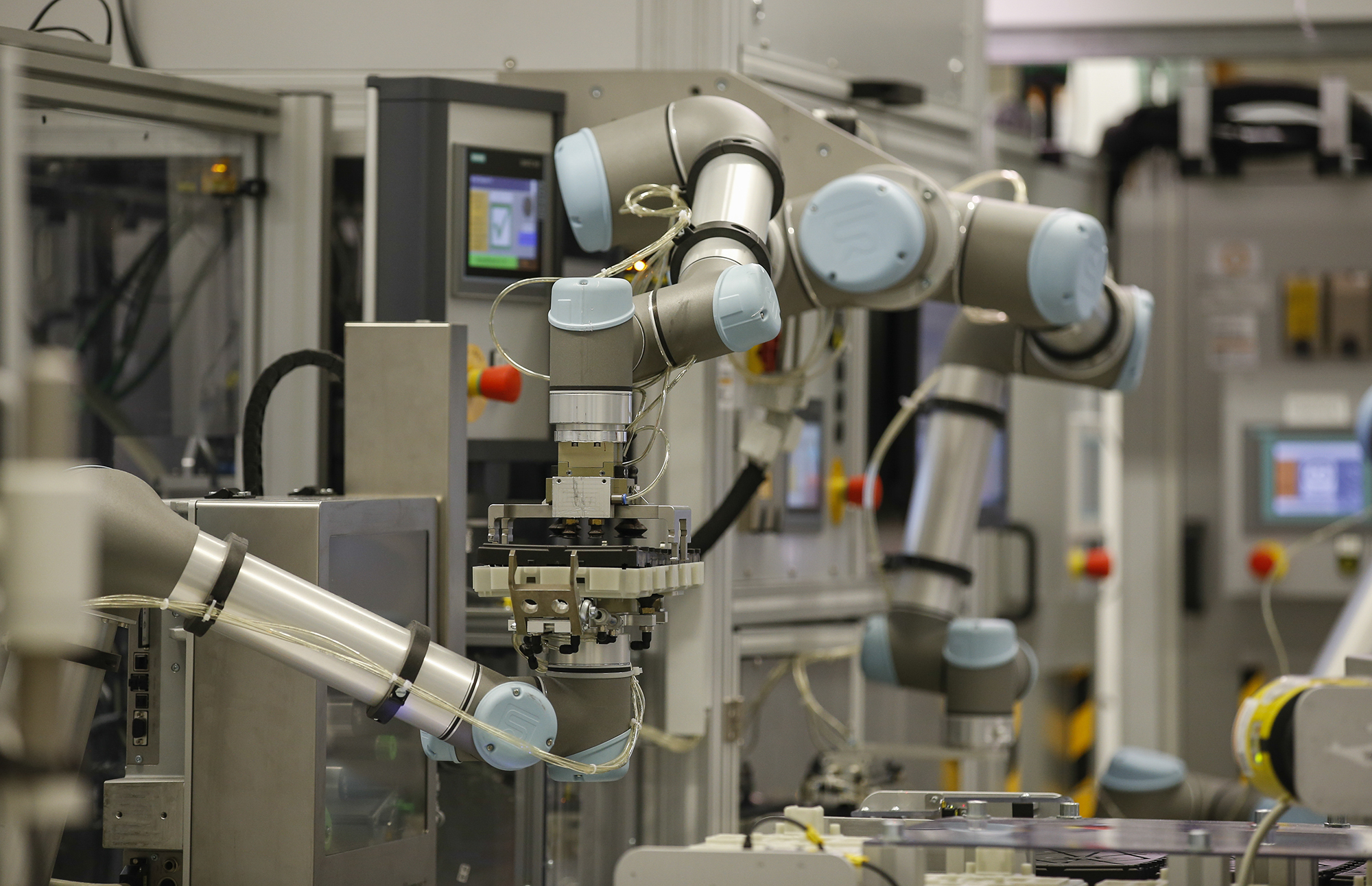

Cobots work with automotive electronics in a Continental work cell.

The demand for robots in AV production cited by the study could apply as well to the development, manufacture and sale of electric vehicles. An EV, as much as any mobility platform in production or slated for the near term, will operate as more of an advanced electronics platform than as a conventional car or truck. It will incorporate powerful and sophisticated electronics, many of which will be miniaturized and applied to three-dimensional molded surfaces to save space and conform to cockpit designs.

These electronics will monitor and control propulsion and provide consumers the selling features they want to enhance their driving and riding experience. Think real-time weather and traffic updates delivered via public or private connectivity services; powerful radar and lidar that enhance driving safety: window displays that report vehicle operations; personal communication systems; and infotainment services.

In vehicles like the current generation of EVs where human control is needed, electronic systems will also alert drivers if they take their eyes off the road, hands off the steering wheel or are otherwise distracted—services that now exist but will be much more accurate in coming years.

Continental One-Piece Curved IP Display

One major step forward for electronics and robotics in EVs is the Curved Ultrawide Display, which will be exhibited by Continental AG at CES 2024 Tech Trends on Sept. 20, in Paris. The display (which Plastics Engineering will report on tomorrow), is reportedly the world’s first curved, pillar-to-pillar auto display. It is 129 cm. (50.78 inches) long, replaces multi-screen displays, and presents driver and passengers with what Continental terms “a seamless user experience” that is interactive and high resolution.

The assembly and installation of this breakthrough in displays doubtless requires the precise and unerring control of advanced robotics.

Meanwhile, the ReportLinker study finds that automotive robotics is already utilized in assembling advanced driver assistance systems for tasks that include adaptive cruise control, lane-keeping assistance and automated parking. Robots also appear in the production stages of AVs, doing welding, painting and assembly.

Robotics Connect Industry 4.0 Manufacturing

The high cost of installing robotics and expenses for maintenance and repairs may limit growth of the market in smaller businesses, the report states. But the rise of Industry 4.0, also known as digital or smart manufacturing, “creates a favorable environment for the automotive robotics market,” the study concludes. “Industry 4.0 relies heavily on robotics to establish a connected manufacturing and supply chain management ecosystem.” As a result, “Robots play a vital role in enabling digital connectivity and are highly resilient to disruptions due to the integration of sensors.”

In market share, Asia-Pacific will remain dominant in automotive robotics in 2030, the study forecasts. The International Federation of Robotics reports that the auto industry in South Korea is the most automated in the world, with 2,867 robots per 10,000 employees; Japan is second in Asia-Pacific, with 1,422 robots per 10,000 employees; and China is third, with 772 robots per 10,000 employees.