Managing Extruder Maintenance in the PFAS-Free Transition

Without PFAS, extrusion systems lose their tolerance for small mechanical flaws. What once ran unnoticed now drives degradation, buildup, and instability.

The move away from PFAS requires processors to rethink more than polymer formulations. It also changes extruder maintenance requirements. PFAS-based processing aids reduced metal–polymer friction and limited die and barrel buildup. This effect reduced the impact of equipment condition on process stability. Their removal increases direct interaction between the melt and equipment surfaces, making wear, surface finish, and cleaning discipline more critical.

Experimental studies in blown film extrusion show that PFAS-based processing aids increase wall slip and reduce time-to-clear at the die. This confirms their role in controlling melt–metal friction and buildup. When processors eliminate these additives, deposits and material retention become more sensitive to screw condition and barrel surface finish. Maintenance now directly controls process stability.

You can also read: Tosaf Introduces New Line of PFAS-free Processing Aids.

Why PFAS Removal Changes the Maintenance Equation

PFAS-based additives delivered low surface energy and high thermal stability, reducing die buildup, stabilizing melt flow, and extending cleaning intervals. Their removal increases direct interaction between the polymer melt and metal surfaces. Friction rises, residence-time effects intensify, and deposits form more rapidly and in less predictable locations along the flow path.

Extruders that operated “clean enough” under PFAS-friendly conditions now reveal dead zones, localized surface damage, and temperature nonuniformity. Maintenance teams report more frequent pressure fluctuations and higher torque demand. These trends indicate mechanical limitations that PFAS once masked.

PFAS-Free Additives Change the Role of Maintenance

PFAS-free processing aids can support extrusion without fluorinated chemistry, but they do not replicate the interfacial behavior of traditional PFAS-based additives. While many PFAS-free alternatives provide pressure reduction and acceptable flow stability, they exhibit different slip and friction characteristics at the melt–metal interface. As a result, they offer less tolerance for surface roughness, wear, and thermal nonuniformity.

Industry evaluations of PFAS-free additives show that extrusion performance becomes more dependent on equipment condition, particularly in dies, adapters, and mixing sections. In this context, PFAS-free additives support processing but no longer mask mechanical limitations.

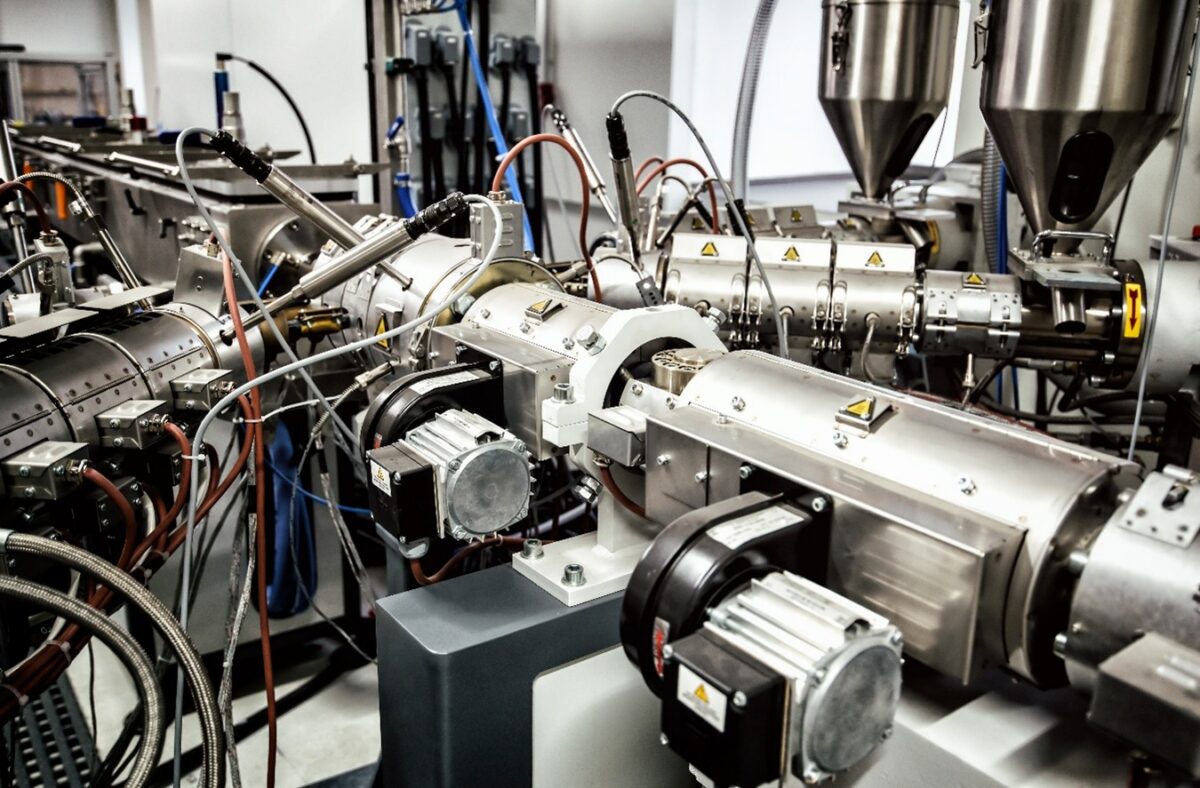

Start With Hardware Reality

Localized polymer buildup at a metal interface. Surface condition and geometric transitions promote material hang-up and deposit formation in PFAS-free extrusion systems. Courtesy of Radical.

PFAS-free processing requires a rigorous assessment of existing equipment. Many extrusion lines still operate with screws and barrels designed for chemistries that relied on fluorinated processing aids. Maintenance teams should evaluate mechanical condition before processing teams adjust formulations. Inspection should focus on screw flights, mixing sections, and barrel liners, where wear and surface damage increase shear variability and material hang-up. In PFAS-free systems, even minor surface defects can accelerate deposit formation.

Die lips and adapters also require close attention. Without fluorinated lubricity, sharp transitions and elevated surface roughness promote faster buildup. Visual inspection and surface roughness measurement therefore become critical inputs for defining realistic cleaning intervals.

Cleaning Frequency Becomes a Design Parameter

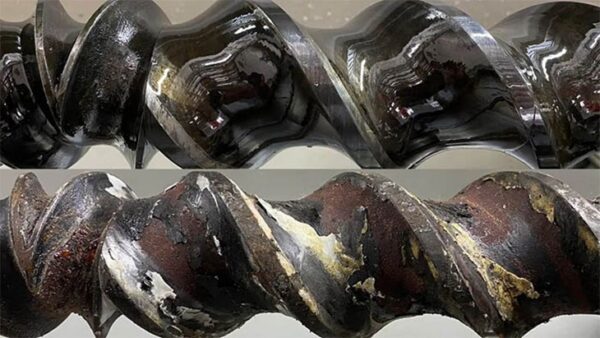

Deposit accumulation on extruder screw flights over extended operating intervals.

In PFAS-free extrusion, reduced tolerance for buildup shortens effective cleaning cycles and increases the importance of timely mechanical intervention. Courtesy of Jwell Group.

PFAS-free operation significantly reduces tolerance for deferred maintenance. Cleaning can no longer function as a reactive intervention. It becomes a defined process variable. Maintenance teams should establish cleaning frequency based on resin family, filler content, and operating temperature. High-output lines often benefit from shorter, more consistent cleaning cycles.

Mechanical cleaning therefore gains greater importance. Removing screws at defined intervals limits the downstream migration of degraded material, while thermal purging alone rarely resolves contamination in PFAS-free systems. Documentation supports this approach, as tracking torque trends, pressure drift, and visual residue patterns enables predictive maintenance and reduces reliance on unplanned shutdowns.

Purging Strategy Needs Mechanical Alignment

PFAS-free purging compounds require greater mechanical cooperation from the extrusion system. They rely on shear and material displacement rather than surface chemistry, which increases dependence on screw design and barrel condition. Maintenance teams should verify that screw elements support effective material exchange, as worn mixing sections or excessive clearance reduce purge efficiency. Inconsistent purging often signals mechanical wear rather than purge compound limitations.

Temperature control also influences purge performance and residue formation. Heaters and thermocouples must operate within tight tolerance. Overheated zones accelerate degradation, while underheated zones trap material and extend residence time. Calibration checks should therefore follow routine maintenance schedules rather than production-driven interventions.

Seal Integrity and Venting Matter More Than Before

Without PFAS, volatile management becomes less forgiving. The loss of fluorinated buffering effects increases sensitivity to oxygen and moisture. Poor seals and ineffective venting allow air and moisture to enter the system, which accelerates polymer degradation and deposit formation.

Maintenance teams should therefore inspect vents, vacuum lines, and seals more frequently. Partially blocked vents promote pressure instability and surface fouling. Worn seals allow air ingress that intensifies discoloration and odor. These conditions rarely appear as abrupt failures. Instead, they develop as gradual quality drift, making preventive inspection essential for maintaining output consistency and protecting equipment life.

The Transition Favors Prepared Facilities

PFAS-free processing requires greater awareness of equipment condition and process signals. Facilities that invest in maintenance and trend monitoring achieve more stable operation. Those that rely on additives to offset mechanical limitations face greater variability. In this context, extruder maintenance directly influences product quality, compliance confidence, and uptime reliability.