Film Extrusion Troubleshooting: Stability, Defects, Control

Film defects are process signals. Connect die flow, cooling symmetry, and winding stress to improve gauge control and roll quality.

Film extrusion is one of the most technically demanding polymer processing operations. Equipment design, control systems, and material formulations have improved significantly. Even so, processors still face recurring problems. These include process instability, film defects, gauge variation, and roll quality issues. Such challenges affect both blown and cast film lines. They often persist despite modern automation and advanced monitoring tools.

A common thread among many of these problems is that they do not originate from isolated faults. Instead, they emerge from interactions among extrusion, cooling, and winding conditions. Understanding these interactions is essential for improving consistency, productivity, and long-term process reliability.

You can also read: Extrusion Troubleshooting – Key Drivers (Part 1 of 3)

Instability as a Root Cause

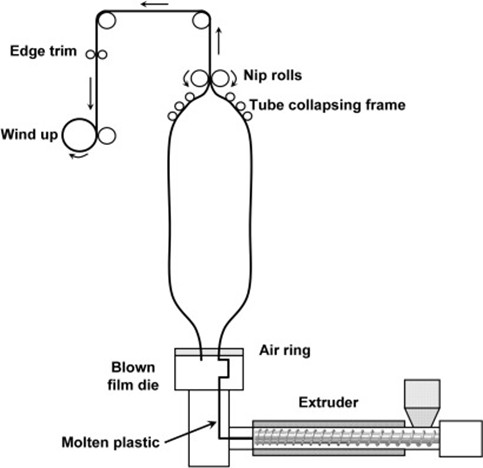

Schematic of a typical blown film extrusion line, showing the extrusion, cooling, collapsing, and winding stages where process interactions influence film quality. Courtesy of Permeability Properties of Plastics and Elastomers (Fourth Edition)

Process instability plays a central role in many film quality issues. In blown film extrusion, small fluctuations in melt temperature, output rate, or cooling symmetry can result in bubble movement, frost line oscillation, and circumferential thickness variation. In cast film operations, similar disturbances may manifest as draw resonance, edge weave, or periodic gauge bands.

These fluctuations frequently remain within acceptable control limits, which makes them difficult to detect in real time. However, their cumulative effect becomes evident downstream, particularly during winding. Industry experience shows that addressing instability at its source often yields greater quality improvements than tightening individual setpoints or adding corrective controls.

Film Defects as Process Indicators

Processors often classify film defects by appearance, but their real diagnostic value comes from what they reveal about process behavior. Surface imperfections, optical distortions, and thickness anomalies usually originate upstream, not at the point of observation. When teams treat these defects as localized quality problems, they trigger reactive adjustments that leave the root causes untouched.

Film industry troubleshooting practices treat defects as process signals, not isolated flaws. For example, recurring streaks or bands often indicate die flow imbalance, thermal gradients, or pressure fluctuations rather than contamination. Intermittent defects usually reflect transient instability instead of steady operating conditions. This view shifts troubleshooting away from symptom correction and towards system-level analysis.

Gauge Variation and Process Limits

Gauge variation is a major economic challenge in film extrusion. Uneven thickness impacts customer requirements, material consumption, energy use, and production rates. Experience across many film lines shows a clear pattern. When processors push output before stabilizing the process, gauge variation usually gets worse.

Effective gauge control depends on alignment among die design, thermal management, draw conditions, and polymer rheology. Automated control systems can handle short-term disturbances. They cannot fix structural imbalances in the process. Lasting improvement comes from addressing the physical sources of variation instead of relying only on corrective feedback.

Roll Geometry and Wrinkle Formation

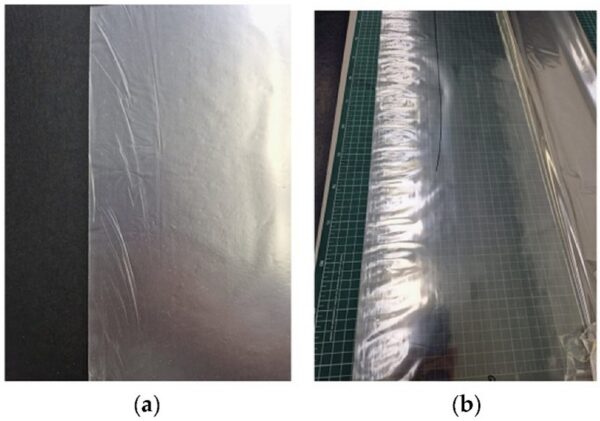

Typical mechanical defects observed during winding, including (a) surface creases and (b) localized edge folds associated with uneven roll build. Courtesy of Overview of the Cast Polyolefin Film Extrusion Technology for Multi-Layer Packaging Applications.

Many film quality issues emerge during winding rather than extrusion. Roll geometry, tension distribution, and winding strategy interact strongly with upstream thickness profiles. Even small edge gauge deviations can create compressive stresses that lead to wrinkles, telescoping, or blocking.

Industrial analyses consistently show that repeated mechanical adjustments at the winder provide limited benefit when upstream variability persists. Effective mitigation requires understanding how extrusion and cooling conditions influence roll build and stress development over time. This reinforces the need for integrated process thinking across the entire line.

Structured Troubleshooting Methods

Trial-and-error adjustments remain common in film extrusion, particularly under production pressure. However, this approach often increases variability and obscures cause-and-effect relationships. Structured troubleshooting methodologies, developed through decades of industrial training and field experience, emphasize isolating variables, observing system response, and documenting outcomes.

These methods reduce downtime, improve repeatability, and help organizations retain process knowledge beyond individual operators. Over time, structured troubleshooting transforms problem-solving from reactive intervention into a disciplined engineering practice.

Towards More Predictable Film Production

Film extrusion rewards control, not brute force. Lines that run predictably waste less material, recover faster from disturbances, and produce rolls that perform as intended downstream. Stability defines the practical limit for productivity. When the process behaves consistently, output increases follow without sacrificing quality.

Understanding how instability develops, how defects reflect upstream behavior, and how roll quality links to earlier process decisions gives engineers practical leverage on the plant floor. These fundamentals remain independent of specific equipment or control platforms. They depend on how polyolefins flow, cool, and respond to stress across the process.