EU PPWR vs US State Laws: Packaging Regulation Trends

Regulating for resilience, safety, and sustainability is crucial in the packaging industry.

The packaging industry is experiencing a rapidly changing regulatory landscape. As regulations shift towards circular economic principles, sensitive sectors may face technical and logistical challenges within their supply chains. Questions regarding product safety, especially in sectors such as food, highlight the need for transparent regulation.

Regulations Across the EU and US

The European Packaging and Packaging Waste Regulation (PPWR) imposes standards for packaging used within, or imported to, Europe. This regulation aims to reduce per capita waste generation and sets recycling targets for 2030. In the United States, many regulations vary from state to state. Many of these regulations focus on post-consumer recycled (PCR) content minimums. Additionally, certain states have taken actions such as banning single-use plastic bags in grocery stores and restaurants.

You can also read: Plastics Compliance Becomes a Business Imperative

Understanding Common Types of Regulation

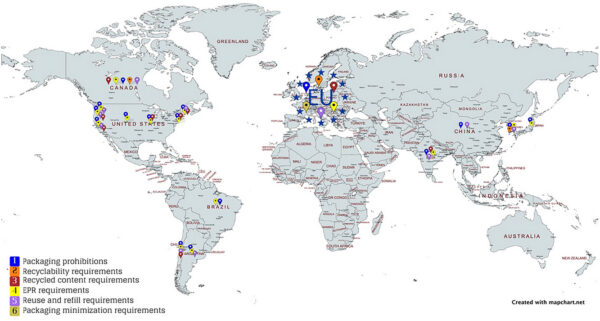

Though the regulatory landscape for packaging varies across the world, current regulatory measures generally fall into five categories:

- Packaging Prohibitions: These regulations ban specific packaging types, such as polystyrene and polyvinyl chloride, due to challenges in recycling. They may also ban packaging including added substances, such as per- and polyfluoroalkyl substances (PFAS).

- Promotion of Reuse and Refill Strategies: These strategies, such as deposit-return schemes, intend to establish systems for packaging reuse. They also set target minimums to increase the proportion of reusable packaging.

- Emphasis on Achieving Recyclability and Increasing Recycling: Strategies to achieve and increase recycling may, for example, establish standards for packaging to facilitate easier recycling.

- Requiring Packaging to Have Minimum Recycled Content: Regulations mandating a percentage of PCR content in packaging reduce reliance on virgin plastic materials.

- Extended Producer Responsibility (EPR) Programs: EPR programs, which hold producers accountable for end-of-life packaging management, are gaining momentum across multiple regions.

Across the globe, new regulatory measures are affecting the packaging industry. Figure courtesy of Impact of emerging packaging regulations on international trade and product safety with emphasis on plastic reuse and recycling in Europe and North America.

Packaging Safely and Sustainably

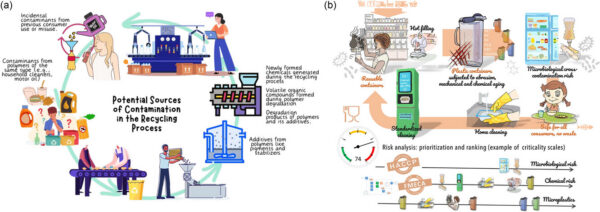

Contamination from ineffective waste collection, additives, and non-food-grade polymers adds complexity to recycling efforts. Cleaning, disinfecting, and continuing to use reusable packaging may worsen its mechanical performance or introduce chemical contamination from repeated sanitation. Under the PPWR, by 2023, 40% of transport packaging must be reusable within a reuse system. Because these materials facilitate transport safety, any loss of mechanical performance could impact their use.

PCR requirements are leading to questions about how regulations can assure product safety. Figure courtesy of Impact of emerging packaging regulations on international trade and product safety with emphasis on plastic reuse and recycling in Europe and North America.

The regulatory landscape of the United States guides the safety assessment of reused packaging through general recommendations. These recommendations are not mandatory, thus, governments at the state and local level can choose to put them into law. Because of this, regulations may vary across jurisdictions. On the other hand, the European Union (EU) harmonizes regulations across member states. Still, they do not currently account for degradation of materials or loss of functional properties after multiple use cycles.

As the plastic industry to a circular economy, variations in regulatory structures may lead to compliance gaps and safety risks. Industry organizations, such as RecyClass and CosPaTox, are spearheading guidelines and safety standards to ensure safety in consumer goods.