Vitrimers in Polyolefins: Processing Control of Crosslinked PE

Dynamic covalent networks allow crosslinked polyethylene to flow, weld, and relax stress during processing.

Polyethylene (PE) dominates many structural and functional plastic applications. Conventional crosslinking locks the molecular architecture. Once crosslinks form, melt flow disappears. Designers gain thermal stability but lose processability, weldability, and repair options.

Dynamic covalent bond exchange enables network rearrangement upon heating while preserving crosslink density. In polyethylene systems, this behavior enables stress-induced flow. It also links molecular exchange kinetics with rheology, forming behavior, and mechanical performance.

Vitrimer chemistry changes rheology, processing windows, and damage behavior in polyolefin systems. In PE networks, these changes link molecular exchange kinetics with forming behavior and mechanical performance.

You can also read: New Polyolefins Meet Demanding Use and Sustainability Needs.

Network Dynamics Beyond Melt Flow

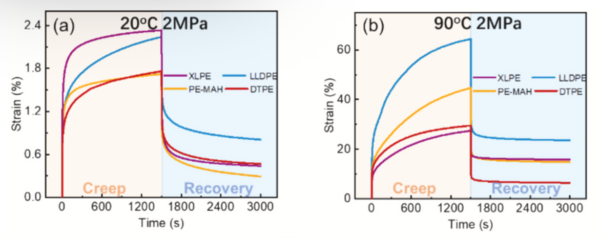

Creep–recovery behavior of XLPE, LLDPE, PE-MAH, and dynamically crosslinked polyethylene (DTPE) under a constant stress of 2 MPa at 20 °C (a) and 90 °C (b), showing temperature-dependent deformation and recovery controlled by network structure. Courtesy of Dynamically cross-linked polyethylene vitrimers: An alternative approach to high-performance high-voltage cable insulation.

In vitrimeric PE, macroscopic flow depends on covalent bond exchange within the crosslinked network. Linear chain slippage plays only a minor role. Stress relaxation occurs through network rearrangement, while temperature controls the exchange rate and defines the transition from elastic solid behavior to processable flow. This behavior matches published creep–recovery measurements in dynamically crosslinked polyethylene.

This mechanism yields a material that resists creep at service temperature but flows during processing. Designers gain a tunable relaxation spectrum instead of a binary solid-or-melt response. Crosslink density determines the elastic modulus. Exchange kinetics control the stress relaxation time. Processing engineers can now tune the chemistry to match specific forming operations, rather than adapting equipment to material limits.

Rheology Under Real Processing Conditions

Oscillatory rheology shows clear differences between vitrimeric PE, thermoplastics, and conventional crosslinked polyethylene. At low frequencies, the storage modulus stays high and reflects the permanent network. Above the bond-exchange activation temperature, the loss modulus rises sharply. This crossover enables extrusion, compression molding, and welding.

Shear thinning in vitrimeric polyethylene follows bond exchange–mediated deformation rather than chain disentanglement. Viscosity decreases with shear rate, even at high molecular weight. This behavior improves flow stability and reduces die swell during extrusion of pipes, sheets, and profiles.

Melt fracture resistance improves as well. The network suppresses elastic instabilities, while dynamic bonds dissipate stress at the die exit. That combination widens the processing window without sacrificing dimensional stability.

Processing-Induced Anisotropy Control

Traditional crosslinked PE locks in orientation from forming steps. Vitrimeric PE behaves differently. During flow, bond exchange allows partial network rearrangement, which relaxes frozen-in stresses. After cooling, the network re-locks in a lower-energy configuration.

This behavior reduces residual anisotropy in thick sections and welded joints. Mechanical testing shows more uniform tensile and impact performance across flow and transverse directions. For rotational molding or compression molding of large parts, this effect reduces warpage and internal stress accumulation.

Processing temperature and residence time control network relaxation. Short cycles preserve flow-induced orientation. Longer thermal exposure promotes stress redistribution. As a result, anisotropy depends on processing conditions rather than mold geometry alone.

Damage Tolerance and Crack Resistance

Conventional crosslinked polyethylene shows brittle crack propagation after microcrack initiation. In vitrimeric networks, bond exchange occurs in the crack-tip region and redistributes local stresses. This effect delays crack growth and preserves network stiffness.

Fracture mechanics tests show increased resistance to slow crack growth, especially under high temperatures or cyclic loading. The material does not self-heal in the classic sense. Instead, it redistributes stress before catastrophic failure. For pressure pipes, geomembranes, and structural liners, this behavior directly affects service life.

Notably, this mechanism does not rely on additives or fillers. The network chemistry itself governs damage tolerance, which simplifies formulation strategies.

Joining and Repair Without Interfaces

Thermal joining under processing temperatures that activate dynamic covalent bond exchange, enabling interfacial continuity, stress relaxation during joining, and recovery of network integrity upon cooling. Courtesy of Miller Plastics.

Welding conventional crosslinked polyethylene remains difficult. Mechanical fasteners and adhesives create weak points. Vitrimeric polyethylene allows direct thermal welding. At high temperatures, bond exchange occurs across the interface. After cooling, the network becomes continuous.

Unlike thermoplastic welding, this process does not depend on chain diffusion alone. Even highly crosslinked regions participate. Joint strength approaches bulk strength, with minimal heat-affected zones. This capability opens design paths for modular structures and in-field repair that previously required material replacement.

Implications for Industrial Adoption

Vitrimeric PE does not replace thermoplastics or thermosets. It occupies a middle ground that aligns closely with industrial needs. Processors gain tolerance to temperature variation, reduced scrap during forming, and expanded joining options. Designers gain predictable mechanical response across a wider temperature range.

The real advantage lies in process-driven material control. Instead of asking how to recycle crosslinked PE, engineers can ask how processing history shapes final performance. Vitrimers make that question meaningful.

As polyolefin applications push towards higher mechanical demands and longer service life, vitrimer chemistry offers a structural upgrade rather than a sustainability add-on.