Solvent-Free Mechanochemistry for Efficient Thermoplastics Recycling

Recycling plastics at scale remains a challenge as waste streams grow more complex. Mixed materials and contamination limit the performance of many recycling routes.

Recycling plastics at scale remains difficult because real waste rarely matches lab conditions. Waste streams include mixed polymers, leftover additives, and contamination. These issues limit both mechanical and chemical recycling. Mechanochemistry offers a solvent-free option that uses mechanical energy to drive chemical change in polymer materials. For thermoplastics, this approach supports practical recycling that fits existing processing lines.

You can also read: Unlocking Business Potential in the Plastic Recycling Market by 2030.

Where Mechanochemistry Fits in Recycling

Mechanical recycling reshapes polymers but does not alter their chemical structure. Repeated cycles lower the molecular weight and reduce performance. Chemical recycling alters the polymer structure but often requires solvents, high temperatures, or complex separation steps. These needs raise cost and add operational complexity.

Mechanochemistry fills the gap between these approaches. Mechanical forces, such as shear and compression, activate polymer chains and trigger reactions in the absence of a liquid medium. This method supports targeted modification instead of full depolymerization. For processors, this means more flexibility when working with recycled thermoplastics.

How Mechanical Energy Drives Chemical Change

Mechanochemistry relies on localized energy input. Shear and stress distort polymer chains and disrupt crystalline regions. These effects create reactive sites such as chain ends or radicals. Unlike thermal processes, mechanical activation concentrates energy at the reaction site rather than heating the entire material. Many mechanochemical studies demonstrate these effects at the laboratory scale using ball milling, whereas industrial applications focus on continuous processing platforms.

Common processing tools in plastics plants can deliver this energy. High-shear mixers, mills, and twin-screw extruders provide controlled mechanical input. Because plants already use this equipment, adoption becomes easier and integration into current recycling workflows can occur step by step.

Reactive Extrusion as an Industrial Platform

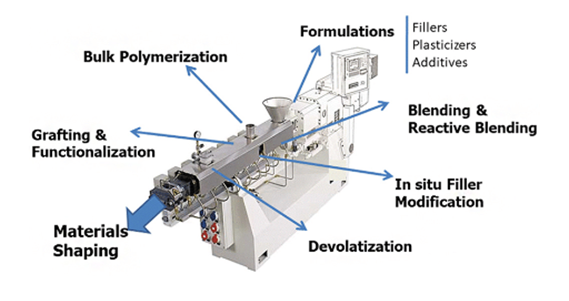

Twin-screw extrusion systems support a wide range of polymer processing and modification operations. Courtesy of UdMachine.

Reactive extrusion represents the most practical route for mechanochemical recycling at scale. Twin-screw extruders allow precise control over shear, residence time, and temperature. Processors can tune these parameters to activate reactions without excessive degradation.

This setup supports continuous operation and stable product quality. It integrates easily with compounding lines. Facilities can adapt existing equipment rather than add new recycling units to carry out mechanochemical modification during standard processing steps.

Molecular Weight Control in Recycled Thermoplastics

One major challenge in thermoplastics recycling involves molecular weight loss. Conventional reprocessing often causes random chain scission, which reduces strength and toughness. Mechanochemistry allows better control of molecular weight.

Processors can balance mechanical energy with additive chemistry to guide chain scission and limit random degradation. This control improves melt flow during reprocessing and preserves mechanical performance. Polyolefins benefit from this method because controlled radical formation supports chain stabilization or branching during processing.

Functionalization and Compatibilization

Mechanochemistry enables solid-state functionalization. Mechanical activation lets reactive additives bond to polymer chains without solvents. This improves blend and composite compatibility, especially in mixed recycled streams.

For example, recycled polyolefins often show poor adhesion with polar polymers or fillers. Mechanochemical grafting adds functional groups that improve interfacial bonding. This strategy upgrades recycled materials instead of only restoring basic processability.

Supporting Recycling of Condensation Polymers

Condensation polymers such as polyesters respond well to mechanical activation. Shear breaks up crystalline structure and exposes reactive bonds. Mechanochemical treatment does not replace chemical recycling for these materials, but it improves process efficiency.

For polyethylene terephthalate, mechanical activation improves solid-state reactions with glycol agents. This step speeds up depolymerization and reduces the need for solvents. Mechanochemistry therefore acts as a supporting process that strengthens existing recycling routes rather than competing with them.

Operational Considerations

High-shear extrusion requires balanced process conditions to limit polymer degradation and reduce equipment wear over time. Courtesy of Janfrex.

Successful mechanochemical recycling requires careful process control. Too much shear causes uncontrolled degradation, while too little energy limits effectiveness. Processors must balance torque, screw speed, and temperature to keep results consistent. Equipment durability also matters. Contaminants and fillers raise wear in high-shear areas. Careful material choice and regular maintenance support long-term operation without loss of product quality.

Environmental and Business Impact

Mechanochemistry cuts solvent use, simplifies plant layout, and shortens recycling paths. It replaces heat with mechanical energy and supports electric and renewable power. These changes improve environmental performance without major plant changes. From a business view, mechanochemistry fits existing processing lines. Facilities can add value to recycled thermoplastics through simple modification instead of material replacement.

This approach does not address every recycling challenge. Instead, mechanochemistry offers a practical, solvent-free option that works under real processing conditions. In thermoplastics recycling, it provides a flexible way to improve material performance, widen usable feedstocks, and support circular design goals.

I recently read your article on Solvent‑Free Mechanochemistry for Efficient Thermoplastics Recycling with great interest and would welcome the opportunity to discuss it further. I am particularly keen to better understand the current state of the art, including the maturity of the processing methods, practical considerations for scale‑up, and how material performance compares with conventional recycling routes. I would also be interested in learning more about early adopters of this approach, the types of polymers and applications showing the greatest promise, and where you see near‑term market opportunities emerging. I believe this could be a highly impactful route for more sustainable, high‑value thermoplastics recycling.