Printable Chipless RFID Helps Sort Plastics—and Washes Off Later

Printable chipless RFID tags using MXene inks enable remote sorting and then dissolve in a caustic wash to avoid contamination of recyclate.

Plastic recycling still struggles with a basic problem: plants cannot reliably distinguish what is on the conveyor belt. Today’s systems depend on visual inspection, SPI codes, NIR/VIS/FTIR spectroscopy, or printed barcodes and QR labels. These methods work poorly with dark or multilayer plastics, dirty packaging, or misoriented items on the belt. As a result, mixed polymers and additives continue to contaminate recycling streams and limit material performance.

You can also read: Flake Sorting: Elevating Plastic Recycling.

A recent study proposes a different approach: printable, chipless RFID tags based on MXene conductors that can be read remotely, tolerate dirt, and then disappear during standard recycling washes. The work targets high-speed, industrial sorting and aims to support higher-purity polymer streams without adding new contamination.

From Optical Codes to Chipless RFID

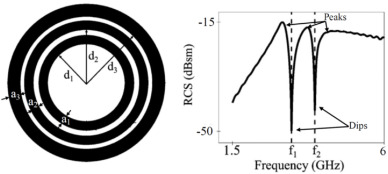

Diagram to illustrate that the size and spacing of the rings produce unique resonance patterns in the CRR’s frequency response. Courtesy of Printing 2D MXene-Based Chipless Radio Frequency Identification Tags to Enable Plastic Waste Sorting for Recycling.

Diagram to illustrate that the size and spacing of the rings produce unique resonance patterns in the CRR’s frequency response. Courtesy of Printing 2D MXene-Based Chipless Radio Frequency Identification Tags to Enable Plastic Waste Sorting for Recycling.

Optical identifiers require line of sight and clean surfaces. In contrast, radio-frequency identification (RFID) can read tags through dirt, curvature, and partial occlusion. Conventional RFID, however, relies on silicon chips and metallic antennas that are expensive, rigid, and undesirable in recycled polymers.

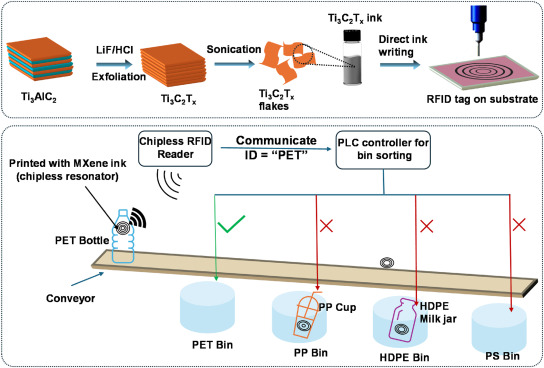

The researchers instead use chipless RFID, in which the tag encodes information through its electromagnetic resonance rather than a silicon microchip. They print conductive MXene (Ti₃C₂Tₓ) traces as concentric ring resonators on plastic films. Each design produces a distinct frequency response over roughly 1.5-6 GHz, allowing scanners to identify packaging by its “spectral fingerprint” at industrial speeds.

Because the tags do not contain discrete electronics, manufacturers can integrate them into flexible packaging at low cost using standard printing-type processes.

Why MXenes? Conductive Inks for Printed Resonators

The team formulates a water-based MXene ink suitable for direct-ink writing on polypropylene (PP) films. PP surfaces normally repel water, so they first treat the film by corona discharge to improve wetting and adhesion. They then print multiple layers of MXene to adjust thickness and sheet resistance.

Higher numbers of printed layers improve conductivity and sharpen the resonance peaks, which increases reading distance and reliability. At the same time, thick conductive patterns can be more sensitive to oxidation and mechanical damage, so the study explores 2-, 4-, and 8-layer configurations to balance performance and stability.

Tag Architecture: Concentric Ring Resonators

Encoding information without a chip requires careful geometry. The researchers design concentric ring resonators (CRR), where each ring behaves like an LC circuit. By selecting ring diameters, spacing, and trace widths, they tune the resonant frequencies f₁, f₂, and higher-order modes.

Different combinations of rings generate unique resonance patterns that a reader can interpret as digital codes. This approach allows a large code space using only simple, planar patterns that are easy to print on films and labels.

Schematic illustration of printing MXene-based inks to form chipless RFID tags directly on plastic substrates, facilitating accurate material identification and improved efficiency in plastic waste recycling. Courtesy of Printing 2D MXene-Based Chipless Radio Frequency Identification Tags to Enable Plastic Waste Sorting for Recycling.

Protecting the Tag: PVA Barrier Coating

MXenes deliver high conductivity but tend to oxidize in air, which degrades their electrical performance over time. To address this, the team applies an ultrathin poly(vinyl alcohol) (PVA) overcoat as an oxygen barrier.

The PVA layer significantly slows the loss of conductivity and preserves the resonance signature over several weeks of storage. Measurements of the reflection coefficient (S₁₁) show that coated tags maintain sharper, more stable resonances compared with uncoated controls. However, the authors note a trade-off: very thick MXene layers provide strong initial signals but can still degrade faster, so optimizing both thickness and coating remains important for commercial deployment.

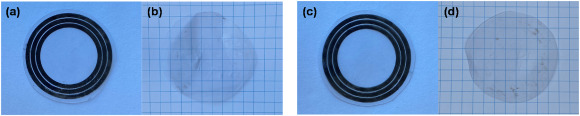

Digital images of a 4L MXene tag (without PVA coating) (a) before and (b) after 5 min of caustic washing and a 4L MXene tag (with PVA coating) (c) before and (d) after 5 min of caustic washing. Courtesy of Printing 2D MXene-Based Chipless Radio Frequency Identification Tags to Enable Plastic Waste Sorting for Recycling.

Disappearing During Recycling: Compatibility with Caustic Wash

Any identification technology for packaging must not compromise the recyclate. Many facilities already use hot caustic washing (1–2% NaOH at elevated temperature) to remove labels, adhesives, and organic residues from polyolefin packaging. The researchers therefore test whether their MXene/PVA tags survive this step—or ideally, whether they detach completely.

Immersion tests in 1% NaOH at 60 °C show that within 3–5 minutes, the PVA film swells and dissolves, and the underlying MXene flakes detach from the PP substrate. After washing, the PP film appears visually clean, with minimal residual MXene, and the RFID resonance signal disappears.

This behavior is crucial: the tag remains functional throughout the collection and sorting stages but self-removes during the standard washing step, avoiding contamination of the recycled polymer.

Implications for High-Purity Recycling Streams

The MXene-based chipless RFID concept directly targets the two biggest pain points in plastics recycling: poor identification and contamination. By attaching a robust, remotely readable code to each item, producers can:

Encode detailed polymer and additive information at the packaging level.

Enable high-speed, non-contact sorting in mixed, dirty, or dark waste streams.

Maintain tag performance during distribution and use, thanks to the PVA barrier.

Remove the tag during existing caustic washing without extra process steps.

For recyclers, this approach promises more homogeneous bales, better process control, and higher-value outputs. For brand owners, it opens the door to digital product passports that survive real-world handling and end-of-life conditions.

Outlook: From Laboratory to Sorting Lines

The study demonstrates a proof-of-concept that combines advanced conductive materials, printable RFID architectures, and compatibility with industrial washing lines. Remaining challenges include long-term MXene stability, large-scale printing consistency, and integration with commercial RFID readers and data systems.

Even so, the work shows how a thin, invisible tag can guide a plastic package through its entire life cycle—from filling line to sorting plant—then vanish at the right moment. As recycling targets tighten and digital tracking gains regulatory support, technologies like MXene-based chipless RFID could become a critical enabler of high-purity, closed-loop plastic streams.