Hyper-nucleated PP for Clear Monomaterial Packaging

Hyper-nucleated polypropylene improves clarity, stiffness and recyclability in rigid packaging by controlling crystallization.

Packaging designers want clarity, stiffness, and recyclability in the same structure. Polypropylene (PP) already fits existing recycling streams and resists many chemicals. However, its semicrystalline structure limits optical performance. Traditional clarifying systems improve transparency, but they often reduce stiffness or narrow the processing window. Commercial nucleator systems already apply hyper-nucleation in PP packaging at an industrial scale. Hyper-nucleated PP changes this balance by controlling crystallization at a different scale.

This material relies on a very high nucleation density during solidification. Instead of slightly shrinking spherulites, hyper-nucleation forces crystal growth to compete as soon as the melt cools. As a result, crystal domains stay uniformly small across the full part thickness, even at cooling rates typical of injection molding and sheet extrusion. This fine morphology directly improves optical behavior.

You can also read: Essential Additives for Plastic Modification.

Crystallization Control Beyond Conventional Nucleation

Optical haze in PP does not come only from the presence of crystals. It forms when refractive index differences appear at crystal–amorphous interfaces near the wavelength of visible light. Hyper-nucleated PP shifts these interfaces below the scattering limit. Light then passes through the structure with minimal deviation, which improves clarity without reducing overall crystallinity.

Unlike random copolymer approaches, hyper-nucleated PP keeps a homopolymer-dominant backbone. This structure preserves flexural modulus, heat resistance, and dimensional stability. These properties remain critical in thin-wall packaging and thermoformed parts, where appearance alone does not define performance.

Transparency Without Mechanical Tradeoffs

Optical gain does not compromise mechanical performance. Hyper-nucleated PP keeps a high level of crystallinity, which supports stiffness and resists creep under load. The fine crystalline structure spreads stress more evenly than coarse spherulites. This behavior limits local deformation during stacking and storage. Packaging components keep their shape and appearance, even at elevated service temperatures.

This balance matters most in clear rigid packaging. Designers often accept lower stiffness in exchange for transparency. Hyper-nucleation avoids this compromise by delivering clarity through morphology control instead of crystallinity reduction.

Solidification Kinetics and Processing Efficiency

Effect of nucleation system on dimensional stability in thermoformed PP cups. Reduced differences between machine direction (MD) and transverse direction (TD) diameters indicate more isotropic shrinkage. Courtesy of Milliken.

Hyper-nucleation changes crystallization kinetics by shortening the induction time before solidification. In injection molding, this behavior allows shorter cooling phases without warpage or sink marks. Molders gain faster cycle times while maintaining optical consistency across cavities and production runs.

Sheet extrusion and thermoforming show similar benefits. The material locks in clarity early during cooling, which reduces sensitivity to chill roll temperature and reheating conditions. This stability widens the processing window and keeps haze and gloss consistent during normal line variability.

Hyper-nucleation also improves dimensional stability by promoting more uniform shrinkage during cooling. In thermoformed parts, this behavior can reduce rim ovality and shape distortion, which helps converters hold tighter tolerances and reduce rejects.

Supporting Monomaterial Design

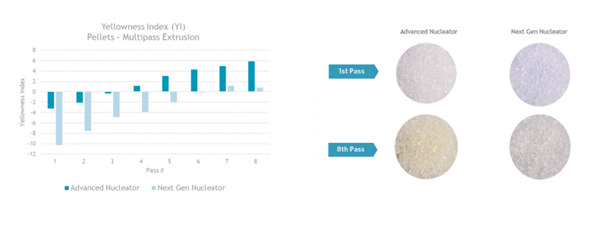

Effect of nucleator system on yellowness index during multiple extrusion passes in PP pellets. Newer high-performance nucleators show improved color stability under repeated thermal history. Courtesy of Milliken.

Hyper-nucleated PP supports a simple monomaterial design. Many clear packages rely on multilayer structures or coatings to look transparent. These designs make recycling harder and reduce material recovery. Hyper-nucleated PP creates clarity by controlling crystallization, not by changing materials. This approach keeps the package fully PP.

Converters also care about appearance when they incorporate regrind. Hyper-nucleated PP can help maintain optical quality across multiple processing passes, which supports internal regrind loops without a rapid rise in yellowing or haze.

This approach fits existing sorting and reprocessing systems. Recycling facilities already recognize PP. Reclaimers understand how it behaves. Clear PP packaging that avoids incompatible layers lowers contamination risk and simplifies material recovery. It does not require changes to recycling technology.

Mechanical Response Under Service Conditions

Clear packaging still faces mechanical demands beyond appearance. Stack loads, creep resistance, and dimensional stability define real-world performance. Hyper-nucleated polypropylene maintains stiffness and heat resistance while improving stress distribution through its fine crystalline structure. Parts resist deformation during storage and transport, even in warm environments.

Living hinge performance also improves with uniform crystallization in thin sections. Controlled morphology increases hinge consistency and fatigue resistance. This behavior allows designers to combine clarity and functionality within a single material grade.

Processing Robustness and Limits

Hyper-nucleation does not remove the influence of processing conditions on optical quality. Excessive shear, thermal degradation, and mold surface defects still affect final appearance. However, the material shows lower sensitivity to normal process variability than conventional clarified polypropylene. Small fluctuations in cooling rate or melt temperature no longer trigger abrupt changes in haze or gloss.

This behavior provides a wider operating window, not complete freedom. The material performs well under controlled processing and tolerates real-world manufacturing conditions better than systems that rely on small crystallinity reductions to achieve clarity.

Where Hyper-Nucleated PP Fits

Hyper-nucleated PP does not replace every clear polymer. It does not match PET for gas barrier performance or polystyrene for glass-like appearance. Instead, it fits applications that need clarity, stiffness, and recyclability within a single material, such as rigid food containers, clear lids, and reusable packaging that requires visual inspection.

By controlling crystallization from the start of solidification, hyper-nucleated PP delivers clarity as a structural outcome rather than a formulation shortcut. This approach preserves mechanical stability and processing flexibility while supporting monomaterial packaging design.