Graphene Nanofillers in PP for Automotive Applications

Graphene nanoplatelets reinforce polypropylene, boosting strength, stiffness and conductivity in lightweight automotive components and ESD-safe parts.

Polypropylene (PP) accounts for around 60-100 kg per vehicle in current production models. However, standard PP lacks mechanical properties required for load-bearing interior components. Graphene nanoplatelets (GNPs) address this limitation through nanoscale reinforcement.

You can also read: The Future of Plastic Compounding.

NanoXplore commercialized graphene-PP compounds in 2024, with Magna International integrating these materials into Chevrolet Silverado EV interior components. This demonstrates viable pathways for nanofiller adoption in high-volume manufacturing.

Material Specifications and Processing

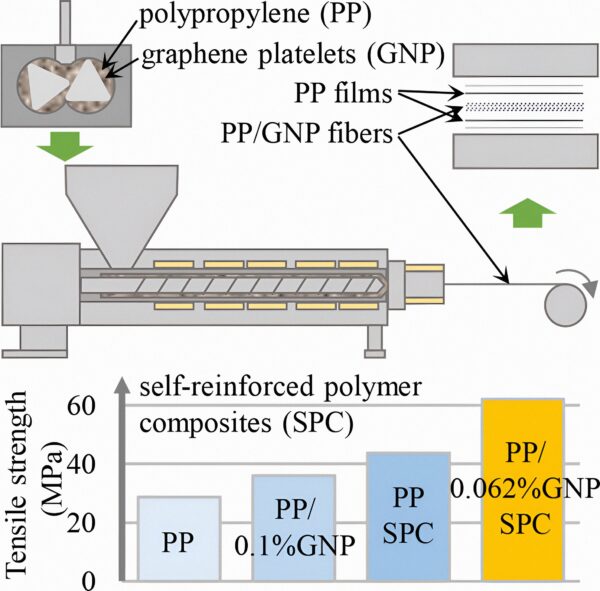

Graphical abstract. Courtesy of The incorporation of graphene to enhance mechanical properties of polypropylene self-reinforced polymer composites.

GNPs consist of stacked graphene layers (6-15 layers) with lateral dimensions of 5-25 μm and thickness between 6-15 nm. Commercial suppliers produce GNPs with surface areas of 50-750 m²/g. Research compared three GNP lateral sizes at 3 wt% loading in PP matrices. The nanocomposites were prepared at 1, 2, and 3 wt% loadings using melt mixing and injection molding.

At 3 wt% loading, the 5 μm GNPs (designated H5) achieved maximum tensile strength of 41.18 MPa. While the 25 μm GNPs (designated H25) reached maximum flexural strength of 50.931 MPa and impact strength of 42.88 J/m. The study found that increasing nanofiller size decreased tensile strength but increased flexural and impact properties.

However, industrial processing involves twin-screw extrusion at 155-195°C followed by injection molding. Researchers developed self-reinforced PP composites with 0.062 wt% GNPs that achieved 117% tensile strength increase. Also, 116% modulus improvement compared to pure PP. Meanwhile, this performance resulted from preventing graphene restacking during melt blending through PP coating.

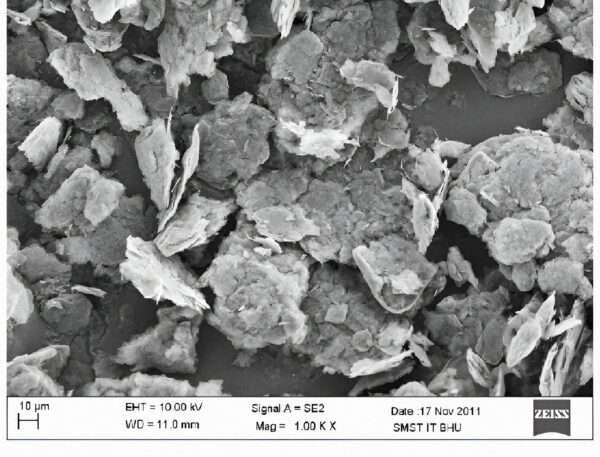

SEM image showing GNP. Courtesy of Influences of carbon nanofillers on mechanical performance of epoxy resin polymer.

Mechanical Property Enhancement

Tensile testing shows consistent improvements. Researchers conducted systematic testing per ASTM standards at 50 mm/min strain rate on 50 mm gauge length specimens. At 1 wt% GNP loading, composites achieved 3.22% tensile strength increase and 39.8% elongation at break improvement. Also, 26.7% impact strength enhancement compared to neat PP. Automotive study using 1 wt% GNPs with 4 wt% talc achieved 38% tensile strength increase and 10% weight reduction.

Furthermore, research on PP-coated graphene showed that at 0.1 wt% loading, yield strength reached 30 MPa (36% increase). Also, tensile strength 33 MPa (38% increase) and Young’s modulus 1.25 GPa (23% increase) versus pure PP. Further, at 1.0 wt% graphene, yield strength increased to 38 MPa (75%) and tensile strength to 37 MPa (54%). While Young’s modulus increased to 1.76 GPa (74%). Elongation at break remained unchanged, maintaining toughness.

There was flexural testing per ASTM D790 in a study. It showed that 5 wt% GNP loading increased tensile strength from 16.5 MPa for neat PP to 20.18 MPa. Accordingly, PP-g-MA compatibilizer addition enhanced interfacial bonding between GNPs and PP matrix.

Electrical and Thermal Conductivity

Researchers studied thermally reduced graphene oxide (TRG) in PP/PE blends. This demonstrated percolation thresholds below 1.0 wt% when TRG was located at blend interfaces. Two-step processing (TRG/PP)/PE achieved lower percolation than one-step processing TRG/PP/PE due to selective interfacial localization.

A study reported melt-mixed graphene-PP systems achieved electrical percolation threshold of approximately 1 wt%. At 4 wt% loading, thermal conductivity increased from 0.27 W/m·K for pure PP to 0.37 W/m·K. This represents 37% improvement. However, electrical conductivity measurements used Novocontrol Alpha spectrometer at frequencies of 10⁻² to 10⁷ Hz. Moreover, electrical conductivity represents the primary driver for GNP adoption in automotive applications requiring electrostatic discharge (ESD) protection.

It was demonstrated that segregated network structures reduced electrical percolation threshold by 2.9 wt% compared to randomly dispersed GNPs. At 10 wt% loading, segregated composites achieved 4.05 W/m·K thermal conductivity and 192.87 S/m electrical conductivity.

Overall, these conductivity improvements enable applications requiring electrostatic discharge protection. Also, it strengthens applications that need thermal management in automotive under-hood components and electronics housings.

Commercial Applications: Current Production Status

The Chevrolet Silverado EV incorporates Magna’s graphene-PP composites in instrument panel supports, door trim reinforcements, and seat back structures. Moreover, Ford Motor Company confirmed that it uses graphene-infused foams in vehicles. The result? Reduced weight and enhanced fuel efficiency. Lyten launched Lyten Motorsports in May 2025. This brought 3D graphene innovations to racing parts.

Perpetuus Advanced Materials announced commercial-scale production of graphene-PP masterbatches for tire manufacturing in 2024. Initial release targets commercial, passenger, and industrial tire sectors, with planned expansion into hoses, seals, gaskets, V-belts, and conveyor belts. Further, this demonstrates market expansion beyond automotive body components into engineered rubber goods.

In contrast, academic research remains at laboratory scale. MIT’s nanostitching work on aerospace composites showed 62% improvement in interlaminar fracture toughness. However, this technology requires vacuum bag resin infusion and autoclave curing unsuitable for high-volume automotive production.

Technical Challenges and Outlook

Achieving uniform GNP dispersion remains the primary technical challenge. Graphene particles naturally clump together. This weakens the plastic if you use too much—above 3 wt%. It ruins the material’s strength. A standard method called melt mixing adds a chemical helper—compatibilizer—to spread the graphene out.

Materials for automotive must pass tough, long-term performance tests—like the SAE J1885 aging tests. Every batch is tested with specific scientific methods. This is to ensure it performs the same way every time.

Transition from laboratory to commercial production validates graphene nanofillers as viable reinforcements where performance improvements justify material costs in weight-critical applications.