Flexible Packaging: Collective Testing Delivers New Insight into Real-World Recycling

A two-year program conducted by CEFLEX gathered information from 1,700 data points and over 600 packaging samples. As a result, a design guide was developed to ensure the practical recyclability of flexible packaging.

A two-year CEFLEX program gathered data from more than 1,700 measurements and over 600 packaging samples. As a result, the initiative developed a design guide that supports recyclable flexible packaging in practice, not only on paper. CEFLEX is a European initiative that works toward the circularity of plastics, with over 180 companies, associations, and organizations. Over the past two years, it has led a multi-country testing program focused on the recyclability of flexible packaging in real-world settings.

You can also read: Flexible and Recyclable: Monomaterial Packaging Meets Sustainability Needs.

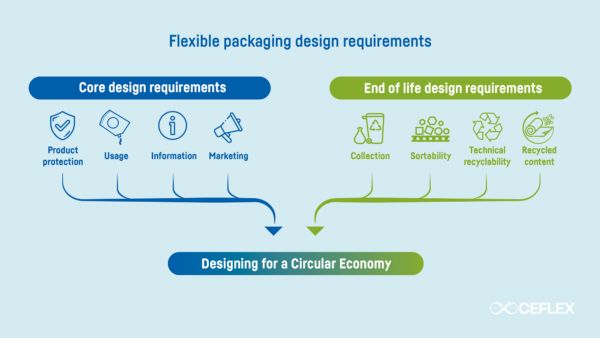

Under the “Designing for a Circular Economy” (D4ACE) program, CEFLEX brought together brand owners, converters, suppliers, recyclers, laboratories, and academics. They tested actual packaging structures rather than relying on theoretical assumptions or isolated laboratory trials. The program covered more than 1,700 data points, 55 materials, and 600 samples across several countries and market conditions. Therefore, it generated a broad and comparable evidence base for design-for-recycling decisions.

In flexible packaging, small structural or formulation changes can significantly alter sortability and recyclability in existing infrastructures. Designing for recycling is now essential, especially given the proposed PPWR target of achieving recyclability for all packaging by 2030. D4ACE set out to clarify what “recyclable by design” actually means in current European recycling systems. For converters and brand owners, the resulting guide supports compliance with recyclability requirements and Extended Producer Responsibility obligations.

Understanding Critical Thresholds

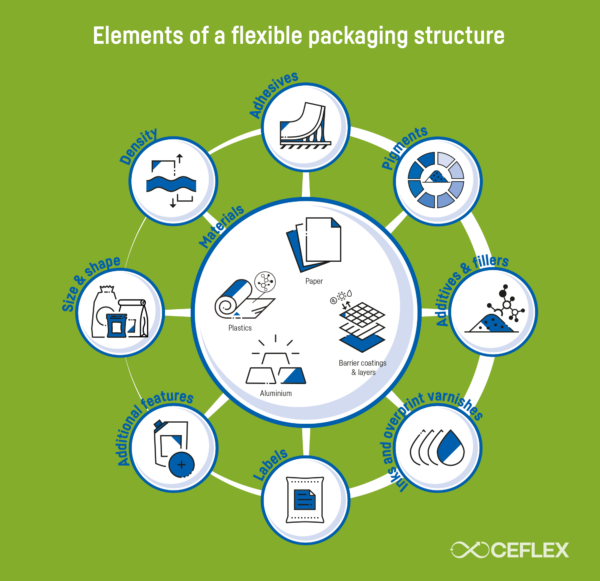

The D4ACE guidance explains which components and conditions most strongly influence the recyclability of flexible packaging. It considers material selection, adhesives, layer structures, sorting behavior, and recyclate quality under realistic processing conditions. For Amcor, which operates across multiple markets, real-world recyclability data proved particularly valuable for internal decision-making. Instead of relying solely on fragmented national guidelines, Amcor can now use harmonized evidence from objective, comparable testing. The program delivered robust results for hundreds of flexible packaging structures tested under controlled, yet realistic, scenarios.

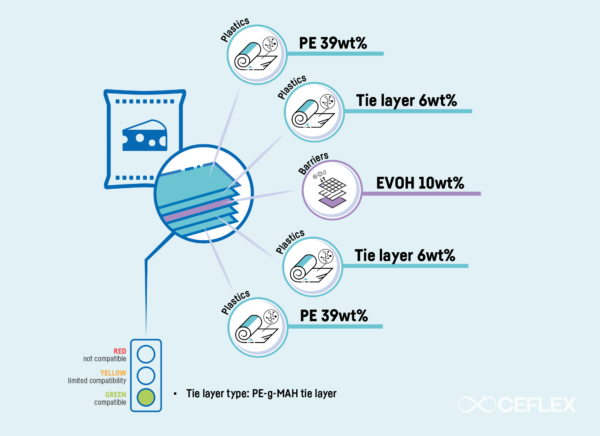

Consequently, D4ACE now defines clearer thresholds for components such as EVOH, inks, and adhesives in flexible formats. “That clarity is critical; it allows design teams to move from theoretical recyclability to performance-based decision-making,” explains Isabelle Jenny. She works as Sustainability Manager at Amcor and closely follows European and international regulatory developments. Jenny emphasizes that these decisions must remain grounded in actual recycling infrastructure realities. Therefore, D4ACE helps teams design packaging that performs technically while also aligning with regulatory expectations. “Adopting D4ACE helps teams align design decisions with future regulatory expectations,” she adds in her assessment. “It also reduces the risk of last-minute redesigns when regulations or EPR schemes become more stringent.”

Adopting the D4ACE guidelines now helps organizations to minimize the risk of future non-compliance, and supports meeting recycled content and recycling rate targets. Courtesy of CEFLEX.

Design Limits for Inks, Graphics, and Additives

From the perspective of inks and additives, D4ACE also delivers robust information to support formulation choices. The guide shows that NIR sorting can handle a broad range of packaging, but design and print strongly influence detectability. Specifically, the design of printed graphics and the choice of ink chemistry have a large impact on NIR recognition. Therefore, the guide offers designers concrete thresholds for particular ink systems, enabling recyclability without sacrificing performance. “One of the biggest gaps was the absence of solid, real-world data on printed and multilayer flexible packaging,” notes Nikola Juhasz. She serves as Global Technical Director, Sustainability at Sun Chemical and participated actively in the program. “The industry has wrestled with this uncertainty for years,” Juhasz adds, referring to inconsistent test methods and assumptions. “What changed the game was the use of engineered base materials and controlled ‘doping’ during testing,” she explains.

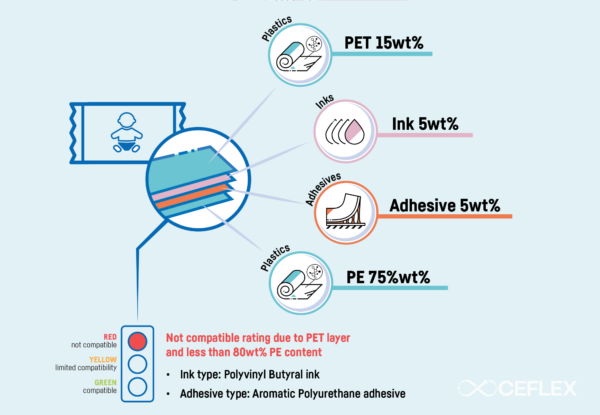

Examples of flexible packaging structures not compatible with recycling under CEFLEX guidelines. Courtesy of CEFLEX.

The team added specific components in a systematic way to evaluate their influence on sorting and recycling performance. As a result, they could directly map commercial product portfolios to updated design guidance and thresholds. “We can now use D4ACE as a shared reference point across the value chain,” Juhasz concludes. “That shared framework reflects the spirit of the project: collective progress built on better data.”

Tracing the Limits of NIR Sorting

Each polymer material exhibits a unique near-infrared (NIR) spectrum that can be measured during sorting. Sorting facilities use NIR technology to identify materials based on their spectral response and thus classify packaging waste streams. Industrial plants today rely heavily on NIR to separate different types of packaging before downstream treatment. Consequently, understanding NIR behavior of flexible packaging is essential for designing structures that remain sortable at scale. Within D4ACE, the Dutch National Test Centre for Circular Plastics (NTCP) conducted part of the NIR testing. The trials provided detailed insight into how flexible materials are detected and classified by industrial NIR systems. Stakeholders delivered around 240 samples to NTCP for controlled testing under NIR sorting conditions.

The team explored roughly ten categories of flexible packaging, including various laminates, structures, and printing approaches. The goal was to determine whether each material combination was detectable and correctly classified by NIR. This approach allowed the project to capture both successful sorting and problematic areas that require design changes.

Detection Challenges: Metallized Films, Clean Samples, and Multilayers

Testing revealed significant challenges for metallized materials, especially highly reflective surfaces. High reflection can overexpose the NIR detector, leading to classification errors and masking the underlying polymer substrate. Printed metallized films mitigated some of these issues by altering surface interaction with the NIR light. In particular, the presence of white pigment or ink improved detectability and reduced classification errors. Dawn Manjaji, Process Engineer at NTCP, notes that NIR also struggled with very clean pre-consumer packaging samples. She attributes this challenge to limited multiple scattering of NIR light within smooth, unblemished material surfaces. “We made adjustments to replicate real-world conditions more accurately,” Manjaji explains when describing the adapted protocol.

For example, the team crumpled samples before testing to better simulate typical post-consumer conditions. For thin films, scratches and surface irregularities promoted increased scattering of NIR emission. Therefore, these imperfections actually enabled better detection and more consistent classification in the sorting system. Multi-layer structures often produce a mixed spectrum that reflects all penetrated material layers. However, if polymers such as PET, PE, PP, or PA exceed roughly 20% of total thickness, NIR can still identify them.

The D4ACE guidelines provide a comprehensive understanding of the components and conditions that impact recyclability, including material selection, adhesives, layering, sorting behavior, and recyclate quality. Courtesy of CEFLEX.

Defining a “New Normal” for Recycled Materials

As the industry transitions toward a circular economy, companies must understand which variations in recyclate quality are acceptable. In other words, they need a realistic definition of what counts as “normal” variability in recycled flexible materials. Dennis Bankmann, independent consultant to CEFLEX, highlights several key findings regarding process and quality variation. He stresses that stakeholders should interpret variations carefully rather than assuming that every change signals a problem. First, he notes that extrusion pressure naturally fluctuates during stable pilot runs. A variation of around 10% in extrusion pressure typically falls within a normal operational window. Therefore, engineers should not automatically interpret such fluctuations as instability in the material or process.

The Design Check Tool helps designers, customer and suppliers accelerate sustainable design and innovation. Courtesy of CEFLEX.

Continuous monitoring remains essential to distinguish between material-driven variation and variation caused by feeding or equipment. Second, visual assessments must follow consistent standards and lighting conditions to remain meaningful. Color differences in pellets or melt can result simply from different illuminations during photography or inspection. “These practical refinements help strengthen confidence in the outcomes,” Bankmann explains when discussing visual evaluations. “They also give the value chain more reliable information to work with when making design decisions.”

Third, the project observed variation between laboratories when running the same tests. These differences did not arise from the test principles, but from specific setups and equipment configurations. When comparing interlaboratory results, Bankmann recommends sharing detailed practices and parameters. For example, in filter assessments, laboratories should align run length, throughput, and extruded mass. This alignment ensures that control and test samples are evaluated on equal terms across facilities. Reporting such protocol details improves measurement comparability and strengthens confidence in recyclate quality conclusions.

Open Access to the D4ACE Guidelines

The D4ACE guidelines are available as open-source resources for the entire value chain. Stakeholders can consult them and integrate them into design processes. By adopting D4ACE now, organizations can reduce the risk of future non-compliance with recyclability requirements. In addition, they can better support recycled-content and recycling-rate targets defined by regulators and EPR schemes. Adopting a shared evidence-based framework offers a practical route toward truly circular flexible packaging. Consequently, it helps align designers, converters, brand owners, and recyclers around common technical realities and thresholds.

The D4ACE are available as open source and can be consulted here.