3D Printing Finds Growth Niches in the Plastics Industry

Insights from K Show: 3D printing finds key niches in plastics, from conformal-cooling tooling to large-format parts and TPU lattices.

More than 40 years after its debut, additive manufacturing has moved beyond speculation and prototype curiosities. Today, tooling, large-format parts, and engineered lattice structures clearly show how 3D printing occupies real, commercial niches within the plastics industry.

You can also read: Tooling Digitalization: Applications.

Early discussions in the 2000s often framed 3D printing as a potential replacement for injection molding. Two decades of industrial maturation have proved a different point. Additive manufacturing remains a niche technology, but it has become strategically important—especially when design freedom, customization, or lead-time reduction delivers clear value. The most recent K show highlighted several applications already in production or close to it.

Tooling Manufacturing: A Mature Use Case

Among plastics processors, tooling represents the most established implementation of additive manufacturing. 3D printing enables them to produce inserts and mold components that conventional machining cannot easily create.

Many companies now use additive manufacturing to build inserts with conformal cooling. Multiple suppliers offer solutions that combine variothermal temperature control with conformal cooling to target surface gloss, reduce visible weld lines, and improve cycle times.

HB-Therm, for example, supplies variothermal control units that keep the mold wall temperature above the polymer’s glass transition during filling, then switch to a standard molding temperature during solidification. This temperature profile supports improved surface quality without sacrificing productivity. Companies such as Contura provide contour-based tempering solutions that use conformal cooling channels following the part geometry.

German supplier Witosa presented another interesting tooling application with Monolith: a one-piece hot-runner nozzle produced via selective laser melting (SLM). Witosa uses additive design freedom to optimize thermal insulation and reduce mass through a hexagonal internal structure. According to the manufacturer, this configuration reduces energy consumption by up to 35% compared with conventional hot-runner nozzles.

German supplier Witosa presented another interesting tooling application with Monolith: a one-piece hot-runner nozzle produced via selective laser melting (SLM). Picture by Laura Florez.

Witosa also uses AI-optimized algorithms to tailor each nozzle to the specific application, accounting for the chosen polymer and part geometry. This approach allows designers to configure different melt-outlet options and enhance processing flexibility.

Large-Format Parts: Pellet-Fed Industrial Cells

KraussMaffei has expanded its portfolio to include industrial 3D printing, targeting large-format thermoplastic applications. Picture by Laura Florez.

KraussMaffei has expanded its portfolio to include industrial 3D printing, targeting large-format thermoplastic applications. The company developed a scalable manufacturing cell that integrates a six-axis robot equipped with an extruder head to produce large parts in a single operation.

KraussMaffei markets this technology under the brand powerPrintFlex. Its in-house extruder, printCore, delivers output rates up to 70 kg/h and reaches melting temperatures around 400 °C. Users can integrate the cell into existing manufacturing environments and combine it with rotary tables or milling centers for hybrid processes.

Target applications include:

Designer furniture and architectural elements

Tools for resin transfer molding

Thin-walled automotive parts and large prototypes

Because the system processes standard resin pellets as feedstock, processors can manufacture large components without dedicated tooling while still achieving high rigidity and geometric precision. They can also run fiber-reinforced resins to create lightweight, structural parts. Design teams simply modify the digital file to implement changes immediately, which significantly shortens development time.

Engineered Lattice Structures: Materials and Morphology

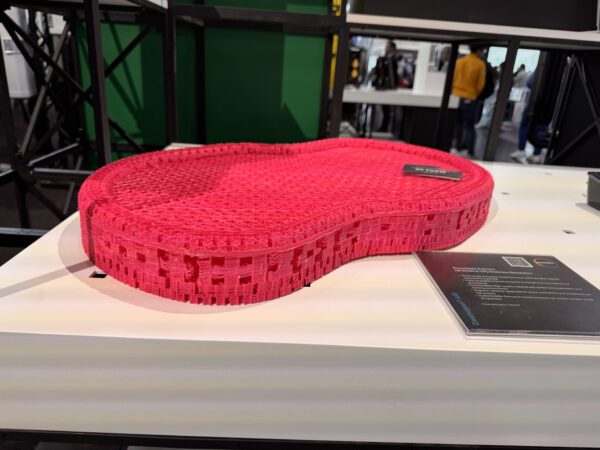

At K, Covestro demonstrated how additive manufacturing can combine polymer chemistry with bio-inspired structural design. Picture by Laura Florez.

At K, Covestro demonstrated how additive manufacturing can combine polymer chemistry with bio-inspired structural design. The company showcased Desmopan® AIR, a TPU-based cushioning concept produced via an extrusion-based process called parallel-layered manufacturing (PLM).

In one example, Covestro and its partner NEVEON produced a baby mattress core with an additively manufactured open cellular structure. This combination of TPU and lattice architecture enabled:

High washability due to open cells

Enhanced breathability and cooling performance

Tunable regional hardness across different mattress zones

The concept uses TPU for both the core and compatible surface materials, which allows recyclers to process the product via thermomechanical recycling as a monomaterial system. This design avoids the recyclability issues that multi-material cushioning systems create when they combine foams, fabrics, and adhesives.

Covestro also presented Desmopan AIR as back-padding for a bag, where additively manufactured lattice zones were integrated through overmolding. This example showed how designers can create customized comfort zones and aesthetic differentiation while maintaining a single-material construction.

The Role of Additive Manufacturing in Plastics

Additive manufacturing does not replace injection molding, extrusion, or thermoforming. Instead, it occupies high-value niches where its strengths matter most:

Complex, conformal, or variothermal tooling

Large-format, pellet-fed components without dedicated molds

Engineered lattices that combine function, comfort, and recyclability

For plastics processors and brand owners, the opportunity lies in identifying where design freedom, customization, or reduced lead time justify a higher cost per kilogram. In those spaces, 3D printing has already moved beyond speculation and now serves as a practical tool within the plastics manufacturing toolbox.