Specialty Additives Boosting Recycled Plastic Properties and Performance

From trash to treasure—specialty additives are turning recycled plastics into high-performance materials that challenge brand-new plastics.

Visualize taking old plastic bottles and turning them into materials strong enough for car parts. That is precisely what is taking place today. Big thanks to specialty additives. As a matter of fact, these chemical helpers are really changing how we recycle plastics. Also, they are making recycled materials work—sometimes even better—than virgin plastics. However, projections show the global plastic additives market will grow from $29.06 billion in 2025 to $36.24 billion by 2030. Therefore, this growth reflects a significant shift toward sustainable plastics.

You can also read: Molecular Recycling for Hard-to-Recycle Plastics.

Why Recycled Plastics Need a Boost

Recycling is not really as straightforward as melting plastic. Also, it is not like making something new. In fact, each time plastic moves through heat and processing, it loses strength. Think of it like photocopying a photocopy—the quality drops. Accordingly, recycled polymers face challenges, such as degradation from multiple heat cycles. As a result, their molecular chains break down. This makes them brittle and weak.

That is where specialty additives come in. These additives act like repair agents at the molecular level. They fix the damage and restore properties that recycling took away.

Chain Extenders: Rebuilding Broken Molecular Chains

Chain extenders chemically reconnect broken polymer chains and restore melt strength and mechanical properties in recycled plastics. Courtesy of Upgrading and Enhancement of Recycled Polyethylene Terephthalate with Chain Extenders: In-Depth Material Characterization.

One of the most exciting innovations involves chain extenders. These additives reconnect broken polymer chains. When plastic degrades during recycling, its long molecular chains change into shorter pieces. Chain extenders use chemical reactions to link these pieces back together.

Moreover, research shows that products like Joncryl and pyromellitic dianhydride (PMDA) can significantly restore melt strength in recycled PET. Chain-extended PET has shown many times better elongation. That is a game-changer for making recycled plastics flexible and durable.

BASF has come up with its IrgaCycle™ additive solutions that are designed solely for mechanical recycling. With the help of these products, the manufacturers can incorporate a greater percentage of recycled content in their products without compromising the quality. The company is particularly focused on addressing challenges like gel formation in film processing.

Compatibilizers: Making Different Plastics Play Nice

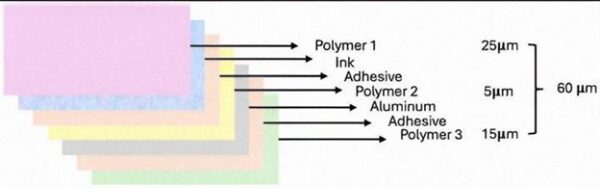

Compatibilizer additives enable the recycling of complex multilayer packaging that previously contaminated recycling streams. Courtesy of Mechanical Properties of Polymers Recovered from Multilayer Food Packaging by Nitric Acid.

Have you ever experienced the mixing of oil and water? That is the case with different kinds of plastics when mixed during recycling. Compatibilizers take care of this problem by acting as molecular bridges. They help incompatible plastics blend smoothly.

This technology matters because recycling streams often contain mixed plastics. Conventional recycling facilities previously could not recycle multilayer packaging—like food pouches with different plastic layers—together. Now, with compatibilizer additives, facilities can process PE films containing up to 20% EVOH or 15% nylon. AMPACET developed additives that comply with the Association of Plastic Recyclers standards. These enable multilayer food packaging to enter recycling streams without contaminating the batch.

Stabilizers: Preventing Further Degradation

Stabilizers act as sunscreen or protection for plastics. They are really resistant to heat, light, and oxygen damage. Recycling processes expose plastics to high temperatures several times. Without stabilizers, this causes rapid breakdown. Two kinds of stabilizers work together in order to provide maximum protection. Primary antioxidants attack the free radicals directly. The secondary antioxidants disintegrate destructive peroxides. When combined, they produce an effect of synergy, that is, they are more effective as a team than as individuals.

RST stabilizer by Baerlocher exemplifies this method. Furthermore, it keeps material integrity unchanged by preventing thermal and oxidative degradation, even after repeated processing cycles. This implies that recycling processes can subject recycled plastics to several lifecycles without losing performance.

Specialty Waxes and Polymer Additives from Molecular Recycling

GreenMantra’s CERANOVUS® additives transform difficult-to-recycle plastics into high-performance specialty materials for construction and industrial applications. Courtesy of GreenMantra Technologies.

Canadian company GreenMantra made a remarkable breakthrough with their new approach. They convert difficult-to-recycle post-consumer and post-industrial plastics into useful specialty waxes and polymer additives by molecular recycling. Their CERANOVUS® product range won the 2025 Plastic Sustainability Innovation Award.

These additives improve asphalt performance in paving and roofing. They also act as melt flow modifiers in plastic applications. A process boosted the output of 100% recycled HDPE corrugated pipe. At just 3% loading level, manufacturers increased melt flow, reduced energy use by 25%, and expanded production by 30%.

This technology tackles plastics that conventional mechanical recycling can’t handle. It turns problematic waste into valuable specialty materials.

Antimicrobial and Functional Additives

The pandemic really increased the demand for plastics that fight against bacteria and viruses. Avient’s Cesa WithStand SX additive keeps clear polymers bright while preventing microbial growth. This matters for medical devices, food containers, and kitchenware.

The addition of these antimicrobial additives guarantees a longer lifespan of the products by stopping bacterial destruction. Also, they lower the risk of contamination in healthcare and food packaging. However, they don’t kill all viruses and bacteria—only stop their spread.

Odor-neutralizing additives had also become popular. Recycled plastics frequently have unwanted smells of previous contents. These additives remove odors and thus produce recycled materials that are more attractive for consumer goods.

Processing Aids for Better Manufacturing

Processing aids allow recycled plastics to flow effortlessly during manufacturing. In fact, they reduce friction and energy consumption. PFAS-free processing aids represent the fastest-growing additive category. Companies like Baerlocher developed products that improve extrusion without harmful forever chemicals.

Desiccant additives are the solution for yet another problem—moisture. Recycled plastics really hold water during the cleaning and sanitizing process. This moisture leads to defects such as “fish eyes” or surface bubbles. Desiccant additives absorb the excess moisture thus stopping these problems.

Real-World Applications Driving Innovation

The automotive industry is a major market for improved recycled plastics. Lightweight, strong polymers replace metal components. This improves fuel efficiency. Chain extenders enable recycled plastics to meet strict automotive performance standards.

PureCycle Technologies developed PureFive™ resin using dissolution recycling. This process removes color, odor, and contaminants from—recycled polypropylene. In 2024, manufacturers made use of it in fiber, injection molding, and thermoforming applications. It was a success.

Construction applications also benefit. Additives help recycled plastics. They are really useful to meet durability requirements for piping, roofing, and drainage systems. Further, these applications demand materials with 20-50+ year lifespans.

Biomass-balanced Plastic Additives

Not all additives support a recycling process. That is true, because degradable additives are really harmful to recycling. They are incompatible with standard polymers and reduce recycled plastic quality. Industry groups like the Association of Plastic Recyclers now classify them as “renders package non-recyclable.”

The industry must balance multiple goals. Also, additives need to improve recycled plastic performance without creating future recycling problems. They should be cost-effective, safe, and environmentally friendly. Bio-based additives show promise for the future. BASF launched biomass-balanced plastic additives in 2023. These replace fossil feedstock with renewable materials, promoting truly—sustainable plastics.

The Road Ahead

Specialty additives are transforming recycling from a downgrading process into an upgrading opportunity. With the right additives, recycled plastics can match or exceed virgin material performance. Meanwhile, the global plastics additives market reflects this shift, projected to reach $36.24 billion by 2030.

In fact, companies worldwide invest heavily in additive research and development. They are creating solutions that make recycled content possible for demanding applications. Overall, this innovation really supports circular economy goals while meeting tough performance requirements.

The message is clear: recycled plastics are not inferior materials anymore. With specialty additives, they are becoming the materials of choice for a sustainable future.