Polyurethane Composites with Industrial Waste Fillers

Rigid polyurethane composites with industrial waste fillers: mechanical strength, thermal conductivity, and machine-learning guided optimization.

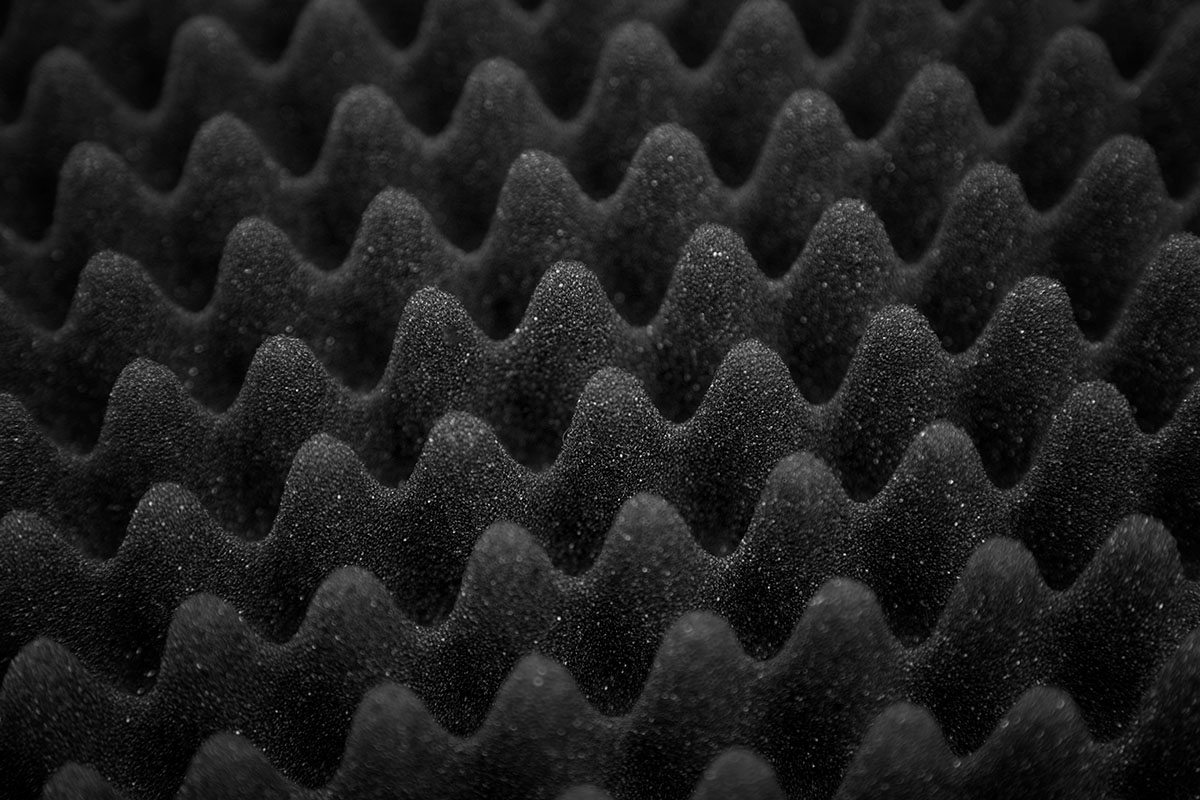

Polyurethane composites with industrial waste fillers support both high performance and circularity in rigid insulation applications. First, researchers developed rigid polyurethane composites using a conventional MDI–polyol matrix filled with salt-clay waste and other industrial byproducts.

You can also read: Lignin Polyurethanes: Byproduct to Solution.

This formulation strategy sought to increase compressive strength and hardness while preserving low thermal conductivity suitable for building insulation systems. In parallel, the study applied data-driven models to quantitatively and predictively understand how formulation variables affect mechanical and thermal behavior.

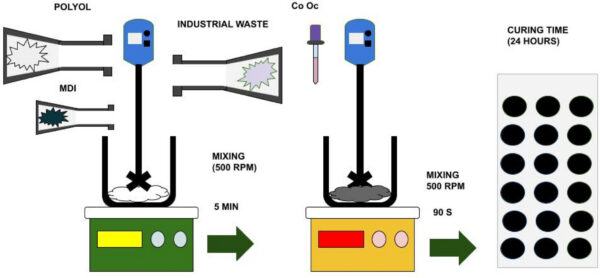

A schematic experimental diagram. Courtesy of Development of Polyurethane-Based Composites With Salt Clay and Industrial Wastes as Fillers: Corrosion, Mechanical Properties, and Machine Learning Insights.

Matrix Design and Stoichiometry

The polymer matrix comprised methylene diphenyl diisocyanate and a commercial polyether polyol with moderate molecular weight and high chemical purity.

Importantly, researchers selected the polyol based on molecular weight, functionality, viscosity, and processing temperature, parameters that govern foaming kinetics and cell morphology. Additionally, a cobalt octoate catalyst accelerated urethane formation, while stoichiometric isocyanate–hydroxyl ratios used one hundred grams of polyol as a reference. Based on this, the team determined the required masses of MDI, catalyst, salt-clay waste, and secondary fillers for each experimental formulation.

Inorganic Waste Filler System

The filler system incorporated several inorganic wastes with distinct chemistries, crystallinities, and particle morphologies derived from industrial operations.

Specifically, the study evaluated ulexite, colemanite, Kırka clay waste, tincal, coal fly ash, and salt-clay waste milled below fifty micrometers.

Consequently, each waste type modified foam density, crosslink density, and cell-wall reinforcement differently, producing broad variations in composite mechanical response. Moreover, boron-bearing minerals introduced potential interactions with isocyanate groups, locally stiffening the polyurethane network around dispersed inorganic particles.

| Waste no. | Type of waste |

|---|---|

| 1 | Salt clay waste |

| 2 | Ulexite |

| 3 | Colemanite |

| 4 | Kırka clay waste |

| 5 | Tincal |

| 6 | Coal ash (fly ash) |

| 7 | Ulexite clay (70 wt.% water) |

| 8 | Colemanite clay (70 wt.% water) |

Mechanical Performance of the Blends

Neat polyurethane foam exhibited compressive strength near 0.13 MPa and hardness around sixty-seven Shore A units under standard testing.

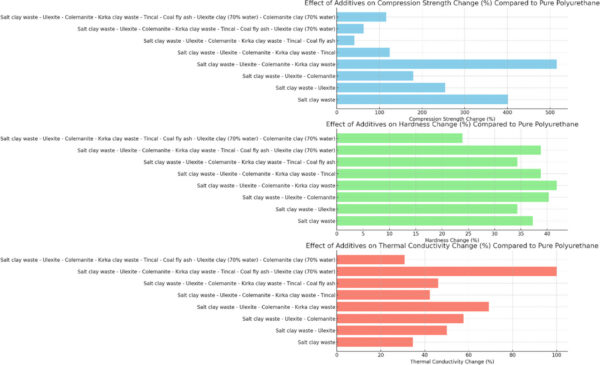

However, waste-filled formulations achieved compressive strength increases between approximately 250% and 500% relative to the neat polyurethane foam.

Simultaneously, hardness improvements reached twenty-five to forty percent, depending strongly on filler chemistry, loading level, and dispersion quality.

In particular, colemanite and salt-clay yielded the highest compressive strength gains, while also delivering the most pronounced hardness increases.

Additionally, Kırka clay waste functioned primarily as a silicate–carbonate filler, increasing composite density and compressive strength without strong chemical interactions. By contrast, fly ash substantially improved compressive strength but contributed modestly to hardness because of its porous morphology and specific surface characteristics. Furthermore, tincal and ulexite enhanced both hardness and durability when homogeneously dispersed, benefiting from their crystalline borate structures within polyurethane. Consequently, engineers can tailor compressive strength, hardness, and density by adjusting filler type, particle-size distribution, and overall inorganic loading.

Thermal Conductivity and Microstructure

Thermal-conductivity measurements used cylindrical specimens and transient line-source equipment, yielding values between 0.030 and 0.050 W·m⁻¹·K⁻¹.

Therefore, even with significant inorganic content, the composites maintained conductivities within typical ranges for rigid building insulation materials.

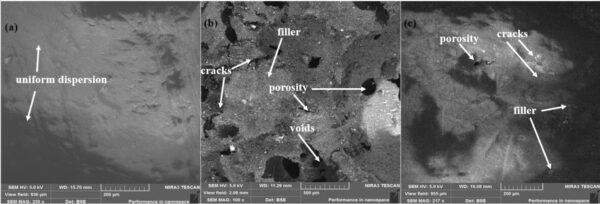

At microstructural level, scanning electron microscopy revealed that optimal formulations combined uniform filler distribution with controlled, relatively closed-cell porosity.Highly porous fly-ash-rich systems facilitated water ingress and exhibited inferior corrosion resistance under aggressive environmental exposure conditions.

SEM images of samples: (a) “13i,” (b) “15i,” (c) “17 m.” Courtesy of Development of Polyurethane-Based Composites With Salt Clay and Industrial Wastes as Fillers: Corrosion, Mechanical Properties, and Machine Learning Insights.

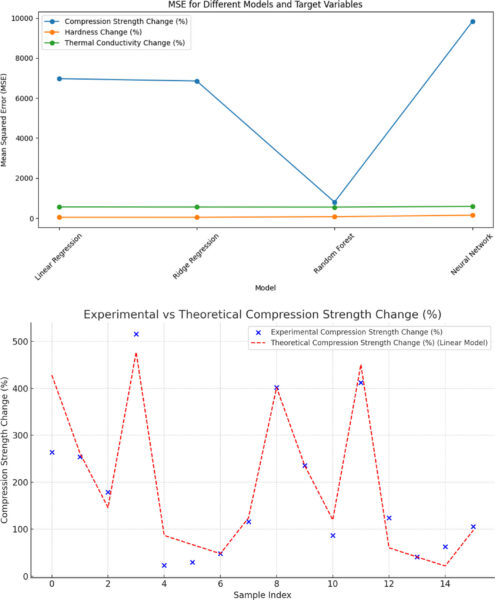

Machine-Learning Models for Property Prediction

To complement experimental testing, the authors trained machine-learning models using formulation descriptors and measured composite properties as input–output pairs.Random-forest algorithms predicted compressive strength and hardness with low mean-squared errors, capturing nonlinear interactions between multiple formulation variables. Meanwhile, a simple neural-network architecture provided the most accurate thermal-conductivity predictions among the evaluated regression approaches. Linear-regression equations quantified individual parameter contributions, clarifying how polymer mass and total waste loading influence hardness and conductivity.

Comparison of machine learning models. Comparison of theoretical and experimental data for compressive strength. Courtesy of Development of Polyurethane-Based Composites With Salt Clay and Industrial Wastes as Fillers: Corrosion, Mechanical Properties, and Machine Learning Insights.

Percentage effects of fillers on compressive strength, hardness, and thermal conductivity. Courtesy of Development of Polyurethane-Based Composites With Salt Clay and Industrial Wastes as Fillers: Corrosion, Mechanical Properties, and Machine Learning Insights.

Implications for Insulation and Circularity

Overall, the study demonstrates that industrial waste fillers can produce rigid polyurethane composites with robust mechanical behavior and acceptable thermal performance. Moreover, integrating machine-learning tools accelerates formulation optimization, reducing experimental workload while preserving interpretable structure–property relationships. Polyurethane systems incorporating salt-clay and related wastes emerge as promising candidates for sustainable insulation and low-load structural applications.