Polymer Aerogels for Advanced Thermal Control

A new generation of polymer aerogels drives significant gains in thermal control across modern industries.

Thermal management in modern systems demands materials with low density, high stability, and strong performance under mechanical and environmental stress. Polymer aerogels enter this field with a profile that meets those needs. Their structure delivers very high porosity, a large internal surface area, and tunable chemistry. These features give engineers direct control over heat flow, moisture behavior, and structural response.

This combination places polymer aerogels as a strong option for insulation, packaging, electronics, and mobility systems. They support applications that require lightweight components with precise, reliable thermal performance.

You can also read: Next-Gen Flame Retardants: Hydrogels & Aerogels.

Performance Gains Beyond Traditional Aerogels

A thin polymer aerogel piece highlights the optical and structural features that make aerogels distinct: low density, high porosity and strong insulation capability within a near-weightless form. Courtesy of Aerogel.

Polymer aerogels differ from inorganic aerogels because they carry more molecular flexibility and offer a broader processing window. Silica aerogels still deliver the lowest thermal conductivity on the market, but they crack easily and create handling challenges. Polymer aerogels avoid those issues and keep their structural integrity during machining, laminating and forming. Their organic backbones tolerate vibration, bending and impact loads that usually damage brittle inorganic networks. This mix of strength and insulation performance opens new design options.

Microstructure That Controls Thermal Flow

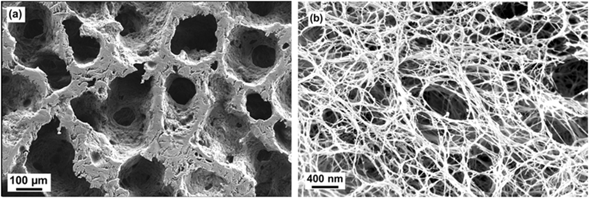

SEM images of a cellulose-derived polymer aerogel showing (a) macroporous network and (b) nanofibrillar scaffold. This hierarchical porosity reduces density while limiting solid-phase and gas-phase heat conduction. Courtesy of Influence of hierarchical porous structures on the mechanical properties of cellulose aerogels.

Thermal conductivity in polymer aerogels comes from solid-phase conduction, gas-phase conduction and radiative transfer. Engineers adjust each pathway through changes in chemistry, polymer structure and pore design, which guide how energy moves through the network.

Polymer aerogels often reach porosities above 90%, a level that restricts solid-phase conduction while lowering density. Narrow pore distributions push gas-phase conduction into the Knudsen regime, where the mean free path of air molecules exceeds pore dimensions and limits collisions. Block copolymer morphology, crosslink density and backbone rigidity further dictate phonon transport, and a tighter network suppresses heat flow across the structure.

Radiative transfer grows stronger at high temperatures, and researchers limit this by adding pigments, opacifiers or IR-absorbing groups that scatter or absorb radiation without adding weight. These additions spread heat through several controlled pathways instead of one, which improves thermal management.

Manufacturing Routes That Enable Integration

The rise of polymer aerogels links closely to progress in scalable manufacturing. Earlier processes relied on supercritical drying, a step that slowed production and raised cost. New solvent-exchange methods, freeze-drying routes and ambient-pressure systems now support steady, efficient fabrication without major capital demands.

Polyurethane, polyimide, polybenzoxazine, cellulose and polystyrene aerogels drive much of today’s development. Each one offers a clear benefit. Polyimide aerogels stay stable at high temperatures, which helps in aerospace and semiconductor insulation. Polyurethane aerogels form flexible sheets that fit complex shapes. Cellulose options add sustainability because they come from renewable feedstocks and break down under controlled end-of-life conditions.

Advances in extrusion, roll-to-roll processing and additive manufacturing continue to widen the design window. Engineers can shape aerogels into films, beads, panels and hybrid multilayers with precise and consistent dimensions. This versatility supports integration into housings, battery packs, insulation jackets and structural components across many industries.

Mechanical Performance for Real-World Systems

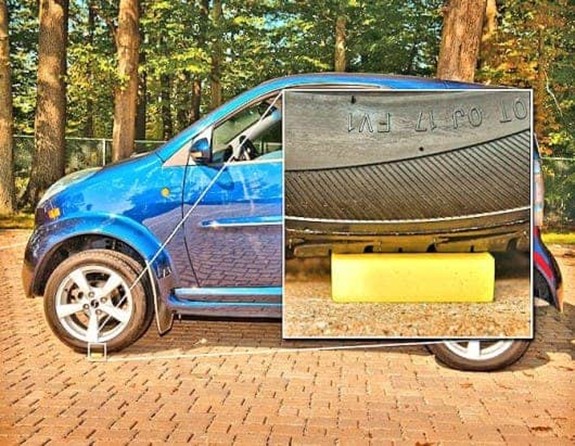

The material absorbs the load without structural failure, which enables designers to place aerogel-based insulation in battery housings, body panels and thermal shields where both heat control and mechanical durability matter. Courtesy of NTRS NASA.

Thermal performance matters only when the material can handle real mechanical loads. Polymer aerogels offer strong compressive resilience and high fracture resistance, and they outperform inorganic aerogels by a wide margin. Their networks deform elastically at low strain and release energy at higher strain through shifts in the microstructure. This response maintains dimensional stability during vibration, thermal shock and assembly stress.

Some high-performance polyimide aerogels reach compressive moduli above 20 MPa while keeping densities below 0.2 g/cm³. These properties make them strong candidates for load-bearing insulation in electric vehicles, aerospace systems and industrial equipment. Their ability to flex without sudden failure also protects nearby components in systems that face large temperature swings.

Applications That Shift With Industry Needs

Next-generation electronics run popular because integration density keeps rising. Polymer aerogels help manage these thermal loads in consumer devices, telecom systems and power electronics. They create barriers that control heat flow, stabilize temperature gradients and protect sensitive parts. Thin-film formats work as thermal interface layers, gap-fillers or board-level insulators without adding significant mass.

Battery technology gains similar benefits. Lithium-ion and new chemistries need protection from thermal runaway, and polymer aerogels slow heat transfer between cells and limit temperature spikes during charge and discharge. Their low density supports lightweight battery packs, which improves vehicle range and device runtime. Packaging engineers also adopt polymer aerogels for cold-chain logistics because the material holds precise thermal boundaries with very thin sections, boosting payload while lowering energy demand.

Construction and infrastructure designers now test aerogel-enhanced composites for building envelopes that must meet stricter energy-efficiency targets. These systems deliver high R-values in thin profiles, which supports retrofits and new structures in dense urban environments.

Sustainability and End-of-Life Pathways

Sustainability considerations shape every stage of polymer development. Aerogels bring both challenges and opportunities to this discussion. Their high porosity cuts material use and lowers transportation emissions. Their strong thermal performance also reduces energy demand during product operation. At the same time, multi-component formulations and crosslinked networks create recycling hurdles.

Research now targets bio-based aerogels from cellulose, lignin and chitosan. These materials give strong insulation and still support biodegradation under controlled industrial conditions. Other teams work on reversible crosslink systems that break down the network and recover monomers. Mechanical disassembly also improves and now separates aerogel layers from composite parts with less effort.

A Platform Material for the Next Decade

Polymer aerogels now move beyond laboratory work and enter high-value industrial applications. They manage heat with precision, handle complex mechanical loads and integrate well into diverse systems. These strengths position them as a platform material for the next generation of thermal engineering.

As manufacturing capacity grows and sustainability strategies improve, polymer aerogels gain a stronger role across major sectors. They support lightweight, high-performance components in electronics, mobility, packaging and energy infrastructure.