Limiting Volatile Organic Compounds in PP Wood-Plastic Composites

A recent study investigated how additives can reduce odor emissions from wood-plastic composites (WPCs), increasing their applicability for indoor use.

Odor emission is a significant barrier for WPCs made from polypropylene (PP), particularly recycled PP. The emission of volatile organic compounds (VOCs) during PP degradation causes these odors. Adding wood fibers to PP exacerbates this issue because of the VOCs in wood. These include formaldehyde, acetaldehyde, and acetic acid. WPCs made from PP are cost-effective, moisture-resistant, and chemically stable. As manufacturers move to use more sustainable materials, incorporating recycled materials into WPC can lower their environmental impact. By addressing VOC issues, manufacturers can find new opportunities for WPCs in consumer goods, such as indoor furniture.

You can also read: Welding Wood-Plastic Composites.

VOC-Absorbing Additives

Certain additives show promise for their ability to absorb VOCs within polymer matrices. These include halloysite nanotubes (HNTs) and β-cyclodextrin (β-CD). HNTs are aluminosilicate minerals with a hollow, tubular structure. Their high surface area, dual surface charge, and large aspect ratio make them a promising candidate for this purpose. β-CDs are cyclic oligosaccharides with a hydrophobic cavity and a hydrophilic outer surface. They can form stable complexes with aromatic hydrocarbons.

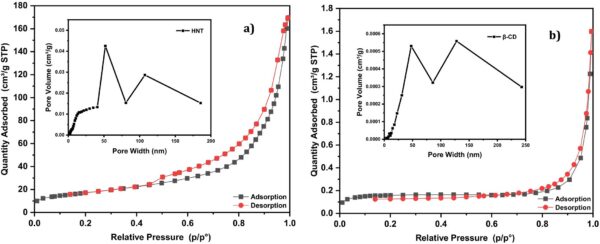

Researchers conducted a Brunauer-Emmett-Teller (BET) analysis to investigate the adsorption behaviors of HNT and β-CD additives. Figure courtesy of Enhancing Odor Reduction and Properties in Polypropylene-Based Wood Plastic Composites With Halloysite Nanotubes and Beta-Cyclodextrin.

Putting Additives to the Test

In a recent study, researchers investigated the potential of these two additives for reducing VOC emissions in WPCs. In addition, they assessed commercial additives RP53 and PY88TQ. The researchers created WPC samples comprised of 70 wt% PP and 30 wt% wood fiber. These samples included additive concentrations of both 2 and 5 wt% HNT and β-CD, and 2 wt% RP53 and PY88TQ.

The researchers conducted a Jar test, where they rated the intensity of the composite’s odor at various test conditions. Then, they compared data from headspace gas chromatography-mass spectrometry (HS GC-MS) with reference spectra from WILEY7/NIST mass spectral libraries.

Observations from this study included lower odor level ratings from the Jar test with the addition of HNT. Additionally, increasing the wt% of HNT improved HNT’s adsorption capacity.

Researchers identified 48 VOCs using HS GC-MS chromatograms. Figure courtesy of Enhancing Odor Reduction and Properties in Polypropylene-Based Wood Plastic Composites With Halloysite Nanotubes and Beta-Cyclodextrin.

In total, they identified 48 VOCs. After eliminating chromatographic peaks lower than 10% of acetone peak height, the WPC without additives showed 28 VOCs. The samples with additives showed the following number of VOCs:

| Additive | No. VOCs | % VOC Peak Reduction |

| HNT | 24 | 14 |

| PY88TQ | 23 | 17 |

| β-CD | 18 | 35 |

Selecting an Additive

β-CD showed a capability to selectively trap small polar VOCs, such as formaldehyde, aromatic compounds, and benzaldehyde. On the other hand, HNTs offer high-capacity, non-selective adsorption.

Both HNT and β-CD showed benefits for mechanical properties of WPCs. HNT increased the strength and elasticity of the composite. β-CD increased the toughness of the composite, while retaining the material’s total strength. Both additives successfully reduced the odors of WPCs, making them appropriate for indoor applications. Careful additive selection can allow manufacturers to tailor WPCs towards their intended use.