Leasing, Not Landfilling: Rethinking Electronics to Cut E-Waste

E-waste leasing and product-as-a-service models cut electronic waste by improving design, take-back, lease returns, and secure recycling.

Demand for new electronics remains relentless. Users replace phones, laptops, servers, and peripherals every few years—or sooner—even though many devices could continue operating for much longer. Some equipment sits “hibernating” in drawers and storage rooms, while others are discarded or exported to regions where material recovery often occurs under unsafe, informal conditions. In the process, valuable metals and components are lost, and environmental and health impacts continue to increase.

You can also read: TERRA is Tackling the Plague of E-waste.

Addressing this challenge requires more than improved recycling infrastructure. It requires rethinking who owns electronic devices, how users use them, and what happens once the first-use phase ends. One promising strategy is an e-waste leasing model that treats electronics as ongoing services rather than disposable goods.

What Is an E-Waste Leasing Model?

In the conventional model, a manufacturer sells a device, the buyer owns it, and end-of-life decisions are mainly up to the user. In a leasing or product-as-a-service model, the customer pays for access to functionality—such as computing or connectivity—while the provider retains ownership of the hardware and responsibility for what happens next.

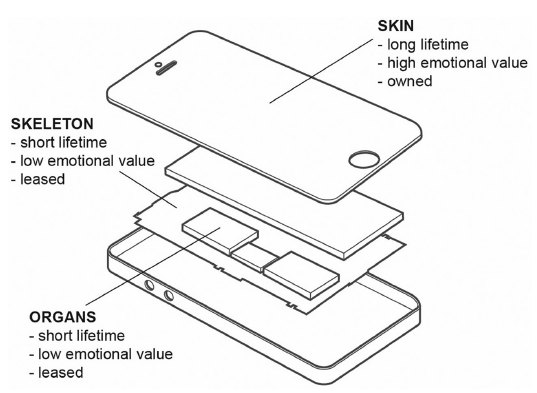

A useful way to think about this comes from research that breaks a device (like a smartphone) into three parts:

Skin – the outer shell that the user sees, touches, and personalizes.

Skeleton – the structural frame and circuit board.

Organs – the electronic components (processor, memory, sensors, etc.) that deliver performance.

We can highlight the functional and emotional value of different parts of a mobile phone by conceptualizing them as the skin, skeleton, and organs. The skeleton and organs often reach the end of their life because they lose performance or technology advances, while the skin typically becomes obsolete through accidental damage or cosmetic wear. Courtesy of Closing the Loop on E-waste A Multidisciplinary Perspective.

In a leasing oriented system:

The provider keeps control of the skeleton and organs and designs them so technicians can open, upgrade, and disassemble them efficiently, enabling component reuse and recovery.

The user may own the skin, and designers make it age gracefully to build emotional attachment so the user keeps it and returns the device for upgrades instead of discarding it. This hybrid approach combines emotional durability (people feel “this is my phone”) with technical circularity (the guts circulate between users).

Why Leasing Helps Reduce E-Waste

Switching to leasing changes incentives throughout the value chain.

1. Better take-back and higher recovery

When the provider owns the core hardware, it has a strong reason to get it back. Devices are collected at the end of the lease rather than forgotten in desks, which creates steady, centralized flows of used electronics. These can be tested, refurbished, redeployed, or sent into controlled recycling streams, improving recovery rates for high-value materials like gold, silver, and tantalum.

2. Design for disassembly and upgrade

If you know a product will come back, you design it differently. Skeletons and organs can be modular and easy to access, so a technician can swap components quickly at a local service point. Research into bio-based circuit board materials goes one step further, exploring boards that can be selectively broken down at end of life to release components and metals with less energy and fewer hazardous chemicals.

3. Matching different lifetimes

Some parts of a device fail or become obsolete much faster than others. Leasing works well with modular design because it allows:

Long-lived structures and components to stay in use across multiple generations

Short-lived or fast-moving parts to be replaced more frequently

Optimized combinations of reuse, remanufacturing, and recycling at component level, not just for whole devices

People Are Central to the Loop

Even the smartest technical model fails if people don’t accept it. Leasing can raise concerns: Will I lose control over my data? Will I be locked into one brand? Will I be pressured into unwanted upgrades?

The “skin–skeleton–organs” concept responds to this by giving people a tangible sense of ownership. The skin can reflect their identity and travel with them across multiple upgrade cycles. Meanwhile, companies manage the invisible, technical parts as assets that circulate through the system. This is very different from anonymous shared devices, which users may treat less carefully and feel less attached to.

Making It Work: Lease-Return Services

Electronics prepared for secure lease returns and recycling at e-Waste LLC. Image courtesy of e-Waste LLC.

For leasing models to work at scale, companies need reliable infrastructure to handle the end-of-lease phase. That’s where lease-return services come in.

Specialized firms can take over the heavy lifting for business and institutional customers by:

Coordinating collection of leased devices

Ensuring secure data destruction, addressing one of the biggest barriers to returning electronics

Auditing, testing, and grading equipment

Managing refurbishing, resale, or certified recycling

Providing detailed reporting for compliance, ESG, and asset-tracking needs

By making returns simple and low-risk for customers, these services increase the likelihood that equipment actually comes back on schedule instead of staying in storage or leaking into uncontrolled channels. They also consolidate used devices into traceable streams, which is exactly what circular business models need.

What a Future E-Waste Leasing Ecosystem Could Look Like

A mature e-waste leasing system might work like this:

Devices are designed from the start for modularity and easy disassembly, with durable, customisable skins.

Customers sign contracts for performance rather than ownership, with clear upgrade and return options.

At end of lease, a logistics and recycling partner collects the devices, wipes data, and sorts them for second life or material recovery.

Components that still have value go back into refurbished products or internal redeployment; the rest go into advanced recycling with strong environmental controls.

Digital product passports and transparent reporting provide traceability and prove compliance with evolving regulations.

From Linear to Circular

E-waste is not only a waste problem, it is a design and business-model problem. As long as success is measured by selling more new devices as quickly as possible, we will keep generating mountains of electronic waste.

E-waste leasing models won’t fix everything on their own. But by aligning ownership, design, reverse logistics, and user experience, they offer a realistic path toward electronics that are used longer, recovered more often, and wasted less.