How Xact Metal Conformal Cooling Cut K-Rain Cycle Time 20%

K-Rain cuts sprinkler molding cycle time by 20% using Xact Metal 3D-printed Corrax inserts and conformal cooling for better quality.

K-Rain, a leading manufacturer of irrigation products, set a clear goal: increase productivity by cutting injection-molding cycle times for a sprinkler head component. Their first attempt, using stainless-steel inserts with conventional straight cooling rods, did not provide the gains they expected.

You can also read: Affordable Metal-Additive Manufacturing for the Plastics Industry.

To unlock further efficiency, K-Rain partnered with Michigan-based mold builder Zero Tolerance LLC and turned to metal additive manufacturing and advanced tool steel.

The Challenge: Faster Cycles Without Compromising Quality

The sprinkler head mold needed shorter cycle times while maintaining surface quality and dimensional stability. Traditional cooling channels restricted design freedom. Straight-drilled lines could not reach hot spots effectively, limiting heat extraction and extending cooling time.

K-Rain wanted a solution that offered:

Lower overall cycle time

Stable, repeatable processing

Improved part aesthetics, especially reduced sink marks

They recognized that achieving these goals required a new approach to both tooling design and material selection.

The Solution: 3D-Printed Inserts in Uddeholm Corrax Steel

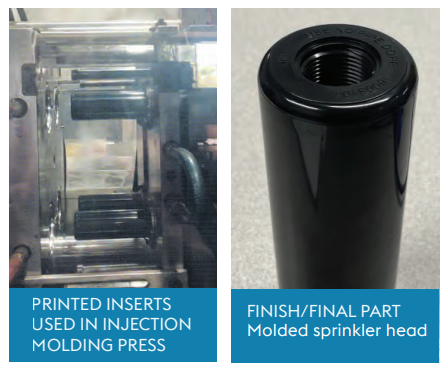

Zero Tolerance proposed a new mold insert design with conformal cooling channels, produced via metal 3D printing. They used Xact Metal’s powder-bed fusion technology and Uddeholm Corrax®, a corrosion-resistant tool steel tailored for additive manufacturing.

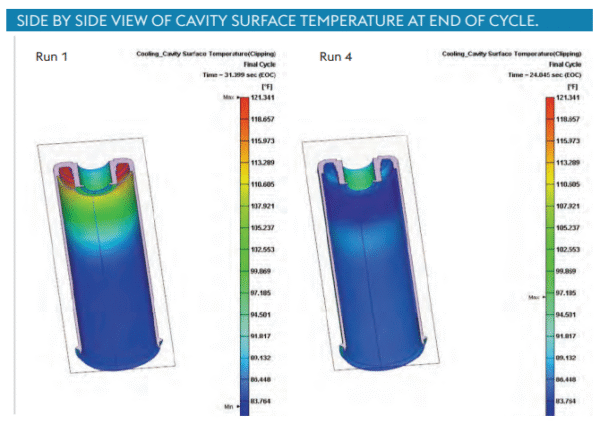

Engineers designed the conformal channels in Cimatron CAD software so the cooling passages followed the cavity geometry closely. This layout allowed coolant to remove heat more evenly across the part. Simulations in Moldex3D validated the concept and predicted at least a five-second reduction in cycle time

Zero Tolerance printed four inserts in Corrax in about 35 hours. After printing, they heat-treated the inserts to 50 HRC, then completed finish machining, EDM operations, and polishing to an A2 surface finish. The result was a robust, corrosion-resistant insert ready for high-volume production.

Simulation in Moldex3d software run by Reaction Plastics Solutions- Temperature at the end of the cycle. Design done in Cimatron. Courtesy of Xact Metal.

Measurable Gains: 20% Cycle Time Reduction

K-Rain implemented process changes in stages. First, they installed a faster hydraulic unscrewing motor, which reduced the cycle time from 52 seconds to 49 seconds. Next, they installed the new conformal-cooled insert. This change cut the cycle time further to 41 seconds, delivering a total reduction of about 20%.

Beyond speed, part quality also improved. The more uniform cooling almost completely eliminated sink marks on the sprinkler head surface. Operators could run the mold more consistently, with fewer cosmetic defects and less risk of warpage.

Sprinkler head mold insert with conformal cooling- Results. Courtesy of Xact Metal.

Looking Ahead: Scaling Additive Tooling Across Production

After this success, K-Rain plans to continue upgrading multi-cavity production molds using Xact Metal’s 3D printing technology and Uddeholm Corrax steel, again partnering with Zero Tolerance for design and manufacturing.

The project shows how molders can use additive manufacturing and conformal cooling to:

Increase throughput without adding presses

Improve part quality and surface appearance

Extend tool life with corrosion-resistant steels

By rethinking cooling with 3D-printed inserts, K-Rain turned a traditional sprinkler head into a showcase for modern tooling and process optimization.