High-Temperature Photopolymer Inserts for Injection Molding

High-temp DLP/SLA photopolymer inserts enable hybrid tooling, short-run injection molding, and faster iteration with stable, metal-like performance.

Photopolymer tooling no longer sits only in the prototyping corner of the industry. DLP and SLA systems now deliver high-temperature, reinforced photopolymers that handle demanding molding environments. These materials reshape the economics of short-run production and unlock new hybrid tooling strategies for processors who want speed without sacrificing dimensional performance.

You can also read: Reduce Thermoforming Mold Production Time & Costs With 3D Printing.

This shift comes from two parallel developments. First, resin suppliers continue to design formulations with higher glass-transition temperatures, improved heat-deflection values, and better fracture toughness. Second, printers now deliver tighter voxel control and more consistent light-exposure profiles. The combination creates inserts that tolerate real processing conditions, not just low-pressure test cycles.

Closing the Gap Between Photopolymers and Metals

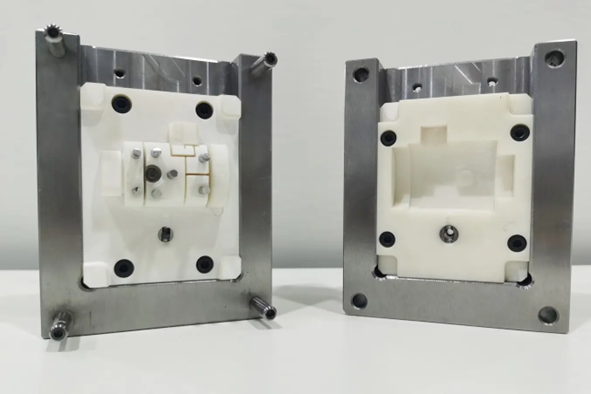

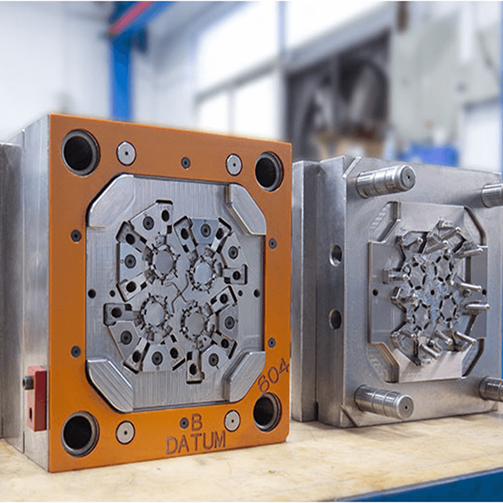

Conventional machined metal inserts are used in standard injection-molding tooling. These assemblies form the performance baseline that high-temperature photopolymer inserts aim to replicate in short-run production. Courtesy of LSR Mold.

Conventional thinking places photopolymers far below aluminum or steel in thermal stability and fatigue resistance. That gap still exists, but advanced chemistries continue to narrow it. Modern high-temp DLP/SLA resins reach Tg values of 180–230°C, depending on network design and filler architecture, and some formulations tolerate even higher short-pulse exposures during fast-cycle molding.

During each shot, the insert sees peak melt temperature for only a brief thermal pulse, so the network relaxes before significant degradation develops. This combination of high Tg, reinforced modulus, and controlled exposure time gives current photopolymers the thermomechanical stability that earlier systems lacked.

Reinforced grades extend performance further. Ceramic-filled variants raise HDT and limit creep under clamp load, while fiber-modified systems increase stiffness and slow crack growth during thermal cycling. These strategies enable inserts to hold dimensional accuracy across dozens—or in favorable geometries, hundreds—of production shots.

Real-Shot Survival Depends on Thermomechanical Balance

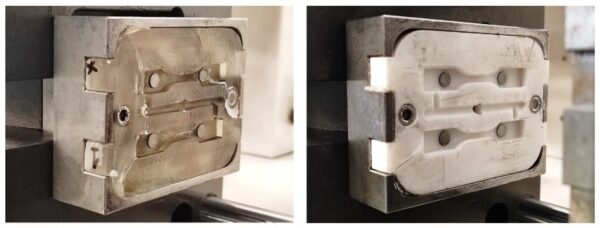

Failure modes in photopolymer mold inserts after real-cycle injection molding. The insert on the left exhibits brittle multi-piece fracture, while the insert on the right shows radial crack propagation originating at ejector-pin locations. Courtesy of Heat Dissipation Plays Critical Role for Longevity of Polymer-Based 3D-Printed Inserts for Plastics Injection Moulding.

Success in the press depends on more than heat resistance. High-temp photopolymers need a balanced thermomechanical profile to tolerate steep stress gradients at the steel–polymer interface. Inserts require enough stiffness to limit deflection under injection pressures above 80–120 MPa. Reinforced grades reach flexural moduli of 8–10 GPa, which stabilizes the cavity. They also need fracture resistance, since brittle networks fail under ejection loads or high shear at the gate. Hybrid crosslink systems, toughening segments, and micro-fillers strengthen crack resistance. Recent research provides detailed insight into stress concentration, thermal gradients, and failure mechanisms in photopolymer inserts.

Thermal conductivity shapes performance as well. Photopolymers dissipate heat slowly, which creates hot spots and delays cooling at gates or rib intersections. This behavior affects crystallization and shrinkage, but processors still achieve stable runs with tuned mold temperatures and cycle timing. Some hybrid-tooling teams even use low conductivity to guide local crystallization in semi-crystalline resins or to moderate shrinkage gradients in thicker sections.

When a Photopolymer Insert Makes Sense

Short-run production benefits most from photopolymer inserts because teams obtain functional cavities within hours rather than wait for machined blocks, enabling faster decisions and tighter development windows. These materials support dense conformal vent networks, controlled micro-textures, and embedded undercuts with high voxel fidelity, which reduces secondary machining and limits manual correction. They also strengthen design-of-experiments programs by letting engineers test new gating concepts, draft transitions, or rib networks in a single day, compressing iteration cycles that normally run much longer.

Hybrid steel–photopolymer systems extend these advantages by distributing mechanical responsibility across the tool. Steel carries high-load regions such as gates, sprues, and wear-critical surfaces, while printed cavities support geometry-intensive zones that drive part function and design evolution. This combination reduces machining, accelerates development, and sustains the dimensional and thermal stability required for consistent processing under demanding injection conditions.

Design Practices That Extend Insert Life

Injection molding subjects photopolymer inserts to steep thermal gradients, high shear, and concentrated compressive loads, so design discipline becomes critical. Generous radii limit stress intensification during pressure spikes, and thicker wall sections distribute clamp force more uniformly, while thin ribs increase fracture risk. Gate placement away from geometric discontinuities reduces shear at the impingement zone.

Because photopolymers retain heat, processors adjust cycle timing or introduce metal cooling elements to stabilize cavity temperature. Surface coatings add further margin by limiting resin adhesion and mitigating micro-damage, especially in reinforced photopolymer systems.

Material Choices Shape Performance

The photopolymer landscape no longer fits a single classification. High-temperature rigid systems provide the strongest thermal stability and dimensional control under elevated mold temperatures. Ceramic-filled grades increase stiffness and raise heat-deflection limits for high-pressure molding regimes, while impact-modified formulations handle complex ejection dynamics or aggressive gate geometries without premature fracture.

DLP and SLA platforms offer distinct advantages. DLP systems deliver high build speed and strong pixel uniformity across large mold faces, which improves cavity fidelity. SLA systems generate smoother surfaces and tighter feature resolution for micro-textures and thin-wall architectures. Both deliver functional inserts when the resin aligns with the specific thermal and mechanical demands of the molding environment.

Towards a New Generation of Rapid Tooling

High-temperature photopolymers have become real tooling materials, not “prototype only” options. Reinforced chemistries, stronger thermal stability, and better fracture behavior let them survive injection cycles and support short production runs. They speed development and work alongside metal tools. As processors push for faster workflows, DLP and SLA inserts gain importance. Designers can print complex molds overnight, mount them in hybrid frames the next morning, and produce functional parts the same day, boosting flexibility, experimentation, and speed across modern plastics manufacturing.

I would be interested if there are tooling shops in the US offering these inserts or what 3D print shops could print something up working with a local tool maker we already use.