Foam Additive Manufacturing for Next-Generation Mono-Materials

Made from polylactic acid (PLA), these mono-material sandwich structures with foam-filled cores offer sustainability and high performance.

Designing mono-material products simplifies the recycling process for end-of-life plastic goods. Recently, researchers developed a high-performance foam that combines mono-material design with sustainable manufacturing processes. Foam additive manufacturing (FAM) eliminates the need for molds and tooling, thus reducing energy and resource consumption. Additionally, FAM’s layer-by-layer approach minimizes material waste during manufacturing. This study resulted in a high-performance foam-filled sandwich structure printed entirely from PLA.

You can also read: Advanced Sandwich-Structured Composites.

In a previous study, researchers found promising performance from entirely PLA honeycomb sandwich structures. Now, researchers seek to improve fully PLA sandwich structures further using FAM.

Advantages of FAM

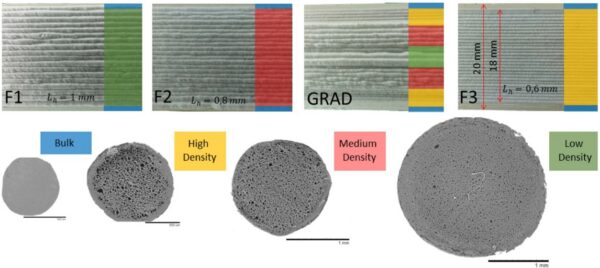

Using FAM technology, manufacturers can tailor foam morphologies to create structures customized to their desired application. For the sandwich structures, bulk PLA foam with a density of 1.24 g/mm3 made up the rigid skin of the specimens.

Bulk PLA acts as the outer skin of each specimen, as shown in blue. Figure courtesy of Mono-material sandwich structures design produced by Foam Additive Manufacturing: study of performances under dynamic conditions.

For comparison, the researchers also fabricated specimens with a honeycomb infill. These samples had similar densities to their foam counterparts.

Testing Impact

The researchers conducted impact testing on the specimens using a drop test machine. Through drop testing, they quantified the specimens’ energy absorption properties using the following parameters:

- Total energy adsorption (J)

- Specific energy absorption relative to mass (J/kg)

- Specific energy absorption relative to density (J*m3/kg)

The F1 (low density) and F2 (medium density) specimens exhibited failure from foam cell collapse. This encompassed upper skin indentation, core densification, and out-of-plane displacement of the specimens’ bottom skin. This behavior is as designed—foam cell collapse is the mechanism that allows energy absorption for the specimens. The F3 specimens, characterized by their high-density foam, experienced interlayer debonding due to their higher stiffness.

Researchers compared impact testing results from the foam and honeycomb specimens. Figure courtesy of Mono-material sandwich structures design produced by Foam Additive Manufacturing: study of performances under dynamic conditions.

The honeycomb specimen with larger cells (B10) failed due to the fracture of their cell walls. Those with smaller cell sizes failed due to horizontal crack propagation. The F1 specimens showed better impact resistance than the B10 specimens. As part of the study, researchers developed a failure map for both the foam and honeycomb specimens. This visualization allows researchers and manufacturers to choose the best material for their specific use case.

On-Demand Mono-Material Structures

When designing mono-material components, FAM allows manufacturers to have control over foam morphology. Density gradients and other custom properties allow for precision during design. Recycled polymers are usable with FAM, and incorporating physical blowing agents like CO2 can further contribute to a circular economy. Additive manufacturing allows for the on-demand creation of components, which, when made of one material, are readily recyclable.

This impact-resistant, mono-material foam has applications in a variety of sectors, including:

- Automotive, for crash absorbers, interior panels, and energy-dissipating systems

- Aerospace, for energy-absorbing layers, thermal insulation, and interior components

- Construction, for thermal and acoustic insulation

Beyond these sectors, the same technology could be adapted for air filtration and liquid purification media, as well as protective and insulating food packaging, where lightweight structures, tunable porosity, and recyclability are critical design targets.

Interesting development, new biobased material + advanced process.