Biopolymer Seed Coatings to Reduce Microplastics in Agriculture

Biopolymer seed coatings cut agricultural microplastics while maintaining adhesion, dust control, and germination for safer, more sustainable farming.

In the agricultural industry, farmers use seed coatings for various reasons. These coatings improve adhesion for seed treatments that protect crops from insects, fungi, and bacteria. Coatings can also improve sowing precision, enhance seed flow, and reduce dust accumulation during seed handling. Furthermore, colored seed coatings allow farmers to identify seeds and differentiate them from untreated seeds.

You can also read: EU Biodegradability Regulations for Agricultural Applications.

Seed Film Coatings

Film coatings for seeds may be comprised of a simple adhesive polymer or a formulated seed film-coating agent. Careful consideration of chemical composition of the seed coatings ensures their applicability for use in agriculture. These coatings must dry quickly to maintain effectiveness and reduce surface contamination. Their adhesion must be sufficient to limit dust but not so high as to inhibit flowability. Additionally, seed coatings should be hydrophilic, releasing seed treatments gradually upon contact with water and promoting germination. At the same time, they must exhibit sufficient hydrophobicity to prevent the rapid leaching of seed treatments into the environment.

Farmers apply film coatings (shown in the leftmost image) in a thin layer to the surface of the seed. Figure courtesy of Transitioning to Microplastic-Free Seed Coatings: Challenges and Solutions.

Limiting Microplastics through Alternative Materials

Conventional adhesive polymers for seed film coatings include polyvinyl acetate dispersion, styrene acrylate copolymer dispersion, and ethylene acrylic copolymer dispersion. To replace these materials and limit the generation of microplastics, alternative materials must meet the same technical and functional requirements.

Recent research suggests using natural and/or biodegradable polymers as alternative materials can lessen microplastic impact in agriculture. These polymers may have additional advantages over conventional materials, as biodegradable polymers may function as a nutrient for soils. These polymers are less persistent in soils and less toxic than common film seed coatings. By switching to natural or biodegradable polymers, farmers can lessen their impact on the environment and increase food safety.

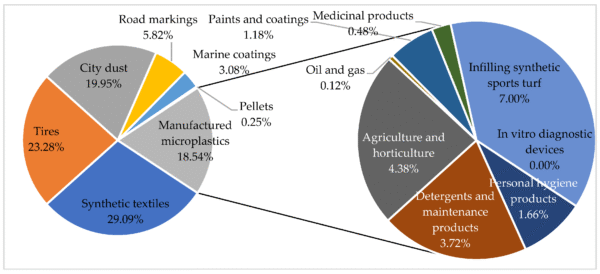

Research suggests that coatings may represent 0.22% of all microplastics released into the environment. Figure courtesy of Transitioning to Microplastic-Free Seed Coatings: Challenges and Solutions.

Researchers have identified polysaccharides and protein biopolymers that comply with EU REACH regulations. Many of these materials demonstrated good adhesion and dust reduction, while maintaining seed physiological quality.

Challenges for the Agricultural Industry

Researching and developing natural and biodegradable polymer film seed coatings can require additional time and cost. Newly developed materials may exhibit different rheological behaviors, thus requiring changes to existing film coating processes. Further research must determine the fate and toxicity of newly developed materials formulated without microplastics. The agricultural industry is shifting to meet changing regulatory requirements and to limit environmental impact. For researchers, agricultural polymers, such as seed coatings, are an avenue for continuing study.