Upcycling PTFE Products with Sodium Metal

A new sodium-based method upcycles PTFE into fluorochemicals at room temperature, reducing PFAS risk and recovering valuable fluorine.

Nonstick cookware and other commercial products often contain PTFE due to its chemical resistance and thermal stability. At the end of these products’ life, disposal can be problematic. The highly durable PTFE does not readily biodegrade; therefore, landfill disposal is not an ideal option. Additionally, the incineration of PTFE requires high temperatures and may release perfluoroalkyl and polyfluoroalkyl (PFAS) substances. These difficulties underscore the need for alternative methods for disposing of PTFE.

You can also read: Advances in PTFE Recycling.

Chemical decomposition of PTFE is of key interest to researchers. Researchers have developed various methods for PTFE defluorination in recent years, but most of these methods are highly energy-intensive. In addition, these methods share a limitation: they do not preserve the fluorine within PTFE. A novel method proposes a rapid and inexpensive approach to upcycling PTFE at room temperature. Using affordable and readily available sodium metal, this method yields excellent quantities of valuable fluorochemicals.

Refining Research

Earlier this year, a group of researchers established a method for the defluorination of PTFE using K3PO4 or K4P2O7. This process successfully captured the fluorine atoms within PTFE, incorporating them into fluorinated fine chemicals. Expanding on this research, Lowe et. al developed a solution for the direct upcycling of PTFE.

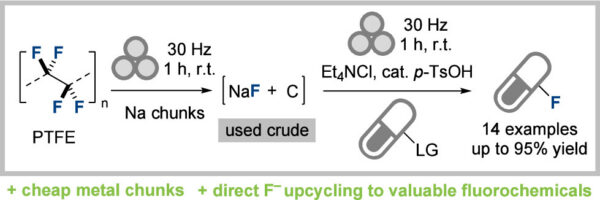

This novel method uses cheap, readily available sodium metal, making it simple and accessible. Courtesy of A Reductive Mechanochemical Approach Enabling Direct Upcycling of Fluoride from Polytetrafluoroethylene (PTFE) into Fine Chemicals.

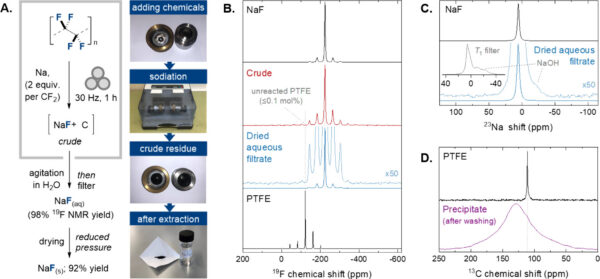

This process uses chunks of sodium metal for the ball milling of PTFE. Researchers found that this process formed a black powder. When analyzed with magic angle spinning (MAS) nuclear magnetic resonance spectroscopy (NMR), signals for PTFE were almost absent. After extraction, this reaction yielded 98% sodium fluoride (NaF) with a byproduct of inert, carbon-rich powder. Without any purification, this product is usable in direct mechanochemical fluorination reactions to produce sulfonyl fluoride and acid fluoride.

This process yields a simple, fluoride-containing mixture that can easily be upcycled into valuable products. Courtesy of A Reductive Mechanochemical Approach Enabling Direct Upcycling of Fluoride from Polytetrafluoroethylene (PTFE) into Fine Chemicals.

A Simple Protocol

This approach offers significant benefits to researchers seeking to overcome the challenges of upcycling PTFE. Sodium metal is inexpensive and easy to access. Additionally, this reaction takes place at room temperature. Many established PTFE defluorination processes require high temperatures, marking the significance of this process.

Many consumer goods make use of PTFE. Cookware, textiles, electrical components, lubricants are just a few of the applications of this fluoropolymer. Advances in upcycling allow for the production of high-yield, high-value substances, while limiting landfill disposal and incineration.