The Gecko Effect: How Shape-Memory Polymers Redefine Smart Adhesion

Shape-memory polymers enable strong, reversible adhesion inspired by nature, advancing smart adhesives for robotics and flexible electronics.

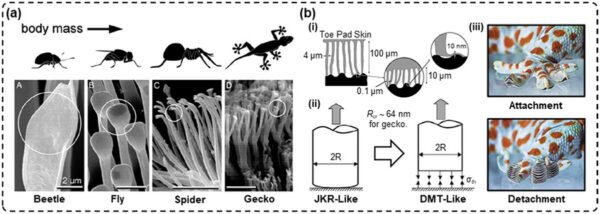

Biological organisms are a source of inspiration for many researchers developing smart adhesives. These adhesives should provide strong adhesion, while detaching effortlessly when needed. Geckos, for example, can cling to rough surfaces using van der Waals forces. This dry adhesion (~100 kPa) occurs due to the presence of millions of tiny, keratinous hairs on the feet of these reptiles. Elastomers designed with biomimetic fibrillar microstructures are an example of how smart adhesive polymers can replicate this phenomenon.

Polymer designers can leverage the exact mechanisms that allow for dry adhesion in nature. Courtesy of Advancing smart dry adhesives with shape memory polymers.

Nevertheless, these smart dry adhesives have limited applications in their current state. The strength of smart dry adhesives decreases as the microstructure size increases, limiting their load-bearing capability. They also exhibit poor adaptability to rough surfaces. Switchability refers to the ratio of maximum adhesion load to minimum detachment load. Finding a balance between adhesive switchability and adhesion strength has proved to be another challenge for researchers.

Shape Memory Polymers (SMPs): A Next-Gen Approach to Smart Adhesives

SMPs, widely used in fields such as aerospace, may offer significant advantages in the realm of smart adhesives. Characteristics of SMPs include a shape memory/locking effect, adaptability, and tunable stiffness. After changing shape, SMPs can revert to their original shape upon stimulation (for example, temperature change). These unique properties can help address some of the challenges associated with traditional smart adhesives. Compared to conventional smart adhesives, SMPs exhibit stronger adhesion, on-demand detachment, and improved adaptability to rough surfaces.

You can also read: How Do Polymer Innovations Enhance Automotive Performance?

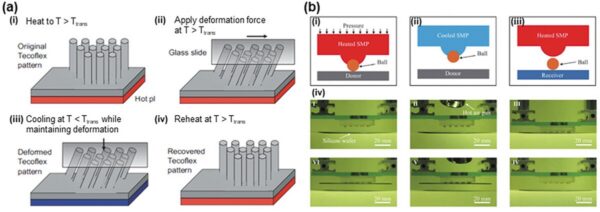

In a 2007 study, researchers designed a SMP inspired by the fibrillar structures on the feet of geckos. The design consisted of two states, with structures at either vertical or inclined orientations. This design required an external force for controlled detachment from the substrate. Recent studies have expanded upon this research by molding the surfaces of SMP adhesives into hemispherical shapes. This approach enabled on-demand detachment and strong adhesion through the locking of embedded shapes.

Controlled by changes in temperature, the hemispherical-shaped SMPs (b) allow for enhanced adhesion switchability on smooth surfaces. Courtesy of Advancing smart dry adhesives with shape memory polymers.

SMP Adhesive Applications

SMP adhesives have a wide range of applications in various industries. For example, the gecko-influenced, hemispherical SMPs show viability for applications in transfer printing. Further research integrated lasers with this technology for use in mass transfer printing of micro-devices for flexible electronics. These advancements may overcome some of the challenges in manufacturing semiconductors using flexible substrates.

Rubber-to-glass (R2G) adhesion, where an adhesive transitions between rubbery and glassy states, can further improve adhesion strength and switchability. This type of adhesion was incorporated into an octopus-inspired design leveraging shape memory hydrogels for use in soft robotics. This approach can improve the gripping functionality of robots when handling fragile objects. SMPs, such as these, offer exciting research avenues for the next generation of smart adhesives.