Surface Modification Strategies to Inhibit Plasticizer Migration

Plasticizer migration erodes performance and elevates compliance risk in PVC products. To counter this, surface engineering gives manufacturers direct, interface-level control.

Flexible PVC anchors critical products in healthcare, packaging, and wire-and-cable. Plasticizers deliver flexibility and processability, but they also migrate. That migration reduces mechanical stability, contaminates contacting media, and triggers regulatory action. Manufacturers need control at the interface without tearing up base formulations or slowing lines. Surface engineering meets that need by shaping the outer microns, where mass transfer starts, and by doing so with scalable operations.

You can also read: Coating to Prevent Plasticizer Leaching in Medical Devices

Plasticizer molecules migrate from the bulk to the surface and then partition into the contacting phase. Temperature, solvent strength, and polymer morphology govern the rate of transport. Programs curb migration by increasing the activation energy for interfacial transfer, decreasing near-surface free volume, or reducing the thermodynamic driving force for partitioning into the external medium. Surface modification acts on these variables while it preserves the base formulation and line throughput.

Mechanism and design objectives

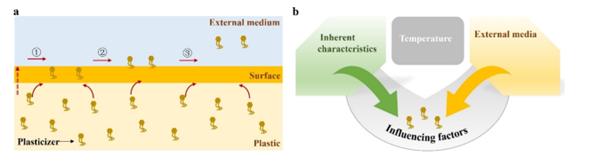

Plasticizer migration and controlling factors. (a) Diffusion from the bulk to the surface, followed by interfacial transport into the external medium (① surface exchange, ② interfacial transport, ③ convective removal). (b) Primary drivers: inherent material characteristics, external media, and temperature. Courtesy of Surface modification strategies for inhibiting the migration of plasticizers from plastics.

Plasticizer migration proceeds by diffusion to the surface and subsequent partitioning into the contacting medium. Surface modification limits this transport by tightening the near-surface network, altering interfacial chemistry, or adding a thin barrier. In practice, migration-control programs establish performance limits with matching release tests. Test matrices cover saline, aqueous alcohol, isooctane, and lipid-rich drug simulants at defined temperatures and dwell times. Plants monitor clarity, gloss, Shore A hardness, weld strength, and kink resistance, and they confirm stability after gamma, e-beam, or EtO sterilization as well as after thermal cycling. Qualification spans tubing, films, and molded parts, with process windows on record and live control charts. With this framework in place, the analysis turns to mechanism-based methods; first, approaches that densify the near-surface network.

Strategy 1: Irradiation to create a cross-linked surface network

Irradiation methods, oxygen plasma, UV, and gamma, confine reactions to the near-surface region. With controlled dose, power, gas composition, and residence time, these processes induce chain scission and recombination within the outer microns, which densifies the network, reduces free volume, and slows Fickian flux. Oxygen plasma also introduces polar groups that interact with common plasticizers and limit interfacial mobility. UV stations can cross-link reactive topcoats in-line within seconds, anchoring the coating to PVC. Gamma aligns with established sterilization workflows in medical production and often yields incremental reductions in migration as teams validate dose maps and post-conditioning.

Process control

Programs tie irradiation dose to flex-fatigue and kink performance to avoid brittle skins and microcracks, then verify uniform coverage in inner lumens and complex geometries with dye-penetrant inspection or cross-section SEM. Teams capture chamber conditions—dose, power, gas composition, pressure, and residence time—in the device history record so audits and lot release rest on documented data.

Strategy 2: Chemical grafting and fluorination to add targeted interfacial chemistry

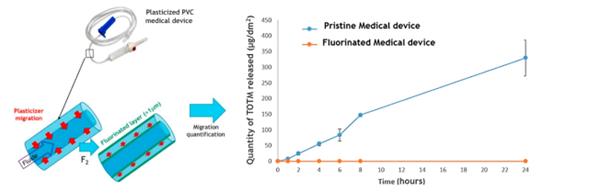

Surface fluorination treatment of medical PVC and migration of plasticizers over time. Courtesy of Surface modification strategies for inhibiting the migration of plasticizers from plastics.

Grafting introduces functional chains that interact with plasticizers and restrict transport. Poly(N-vinylpyrrolidone), PEG-like brushes, and zwitterionic chains can form hydrogen bonds or ionic pairs with phthalates and alternative plasticizers. Those interactions raise local viscosity, lower diffusion coefficients near the surface, and reduce transfer into nonpolar media. Zwitterionic chains also deliver low-fouling behavior in blood-contact devices, which reduces surface conditioning by proteins and lipids.

Fluorination changes the surface energy landscape. A thin fluorocarbon layer lowers surface energy, reduces wetting by hydrophobic fluids, and diminishes the driving force for partitioning. Operators run gas-phase fluorination in batch reactors with strict control of pressure, temperature, and residence time; post-treatments remove unreacted species and stabilize the interface.

Process control

Programs control initiator level, solvent system, and post-wash so residuals meet toxicology limits. Teams track contact angle, zeta potential (as a proxy for zwitterion density), and XPS spectra to confirm functional coverage and stability over time. After fluorination, engineers verify bondability and, when joints fall short, they introduce tie-layers or adjust recipes to maintain solvent-bond and RF-weld strength.

Strategy 3: PECVD and related CVD routes to deposit dense barrier films

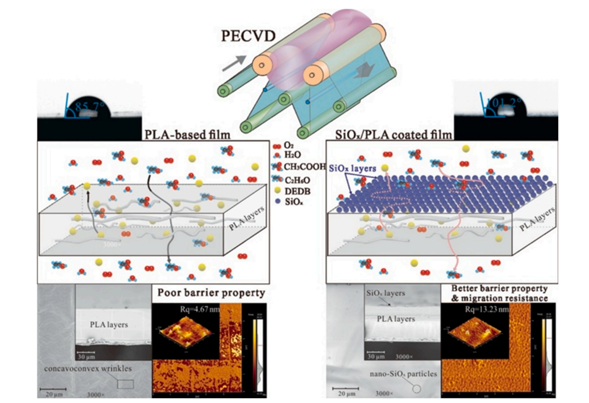

PECVD of nano-SiOₓ shown on PLA for clarity of the barrier morphology. The mechanism translates to flexible PVC, where PECVD barriers cut plasticizer migration while maintaining low-temperature processing. Courtesy of Surface modification strategies for inhibiting the migration of plasticizers from plastics.

PECVD deposits ultra-thin SiOₓ, organosilicon, or diamond-like carbon films at low substrate temperatures. These glassy layers reduce free volume, increase path tortuosity, and block diffusion pathways. Thickness in the 20–100 nm range already shifts migration outcomes and, in parallel, improves oxygen and moisture barrier performance for packaging components.

Process control

Programs add a brief plasma activation step to increase adhesion, then manage intrinsic film stress by balancing precursor ratios, RF power, and chamber pressure to prevent crazing on bends. Teams detect and mitigate pinholes using electrical breakdown tests or reactive dye uptake, and they verify coverage at edges, lumens, and overmolds. Roll-to-roll PECVD supports high-throughput coating on films, while rotary fixtures extend uniform deposition to tubing.

Strategy 4: Solution coatings that form hybrid networks and bio-based nanomembranes

Solution-applied systems deliver strong performance with modest capital. Hybrid sol-gel coatings interpenetrate the surface and form inorganic–organic networks with high cohesion and low permeability. UV-curable acrylate or urethane-acrylate topcoats cure in seconds and provide smooth, defect-lean skins with tunable modulus. Protein- and polysaccharide-derived films can self-assemble into tough nanomembranes that adhere to PVC, maintain flexibility under bending, and suppress migration across aqueous and fatty media. Zwitterionic or carboxybetaine functionalities further reduce lipid uptake and support antifouling behavior.

Process control

Teams engineer rheology for edge coverage and low pinhole density by tuning solids content, solvent blend, and line speed. They add adhesion promoters or mild plasma activation to raise peel strength. During cure, they control humidity and temperature to prevent solvent entrapment and microvoid formation. They confirm thickness and uniformity with ellipsometry or X-ray fluorescence before release.

Test plans that reflect service conditions

Test plans replicate service exposure and time–temperature histories. In medical programs, laboratories challenge materials in 0.9% saline and lipid-rich drug simulants at 37 °C, applying gamma, e-beam, or EtO sterilization before and/or after exposure, as required by the use case. For food-contact applications, teams expose specimens to 10%, 50%, and 95% ethanol, water, and isooctane, then run thermal profiles representing filling, hot-fill, and retort processes. Accelerated aging at 50–60 °C is used only when material kinetics justify it, avoiding artifacts from relaxation.

Analysts quantify migration using LC–MS or GC–MS on extract solutions and confirm interfacial chemistry with ATR-FTIR and XPS. They track mass change normalized by contact area and specimen thickness. Chemical findings are paired with mechanical data—tensile properties, modulus, haze, weld strength, flex-fatigue, and kink resistance—to establish structure–property relationships. Finally, teams evaluate complete assemblies—tubing, connectors, crimps, and overmolds—alongside flat coupons to capture geometry-dependent failure modes.

Outlook

Surface engineering provides interface-level control of plasticizer migration while preserving the PVC formulation and line throughput. The methods align with core mechanisms: irradiation densifies the near-surface network; grafting and fluorination tune interfacial chemistry; PECVD and solution coatings establish thin, effective barriers. With media-specific limits, sterilization and thermal-cycle verification, and documented process windows, teams hit migration targets without sacrificing clarity, flexibility, weld strength, or throughput. This mechanism-driven approach, paired with disciplined qualification, keeps flexible-PVC programs compliant.

Read the full article here: Surface modification strategies for inhibiting the migration of plasticizers from plastics.