Plastic Waste to Hydrogen—and Lubricant Additives—for H₂ Engines

Turning mixed plastic waste into hydrogen fuel and carbon nanomaterials for H₂ engines and advanced lubricant additives.

Hydrogen engines move from pilot trials to fleet deployment, where operators expect reliability, low emissions, and compatibility with legacy hardware. That transition elevates thermal loading on rings, liners, and bearings, while water in blow-by intensifies corrosion control inside the crankcase. In parallel, municipal systems are delivering increasing volumes of heterogeneous post-consumer plastics with variable quality and moisture content.

You can also read: Energy Storage with Plastic-to-Carbon Conversion.

An integrated thermochemical platform can address both pressures. A single line converts mixed polymers into hydrogen and refinery-range hydrocarbons for energy, while the same train produces carbonaceous solids that enhance lubricant formulations for H₂-ICE service. Plant teams, formulators, and fleet managers thus align around a process that advances circularity and stabilizes operating costs.

Feedstock Reality

Inbound bales rarely conform to specification. Polyolefins predominate, while PVC and PET occur in material proportions with labels, food residues, and fines. Sorting lines remove metals via magnetic and eddy-current separation; optical systems divert chlorine-rich fractions. Low-temperature dryers extract free moisture without inducing thermal degradation. Calcium sorbents neutralize acid gases at the front end. Laboratory teams quantify chlorine, total acid number, and oxygen content with rapid assays, then consign each lot to the appropriate reactor train. This operating discipline preserves catalyst activity, protects seals and heat-transfer surfaces, and maintains downstream hydrotreaters within a defined safe window.

Process Windows

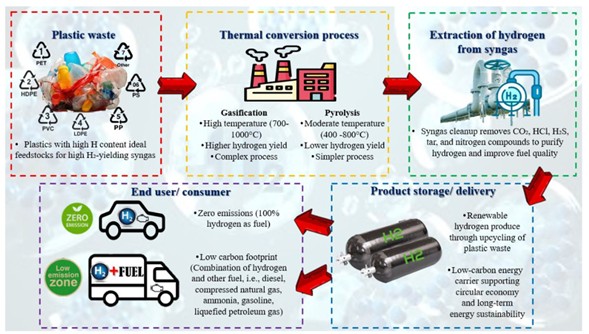

Overview of upcycling plastic waste into hydrogen fuel through thermal conversion and extraction processes. Courtesy of Thermal conversion of plastic waste into fuels and lubricant additives for hydrogen internal combustion engines: A systematic review.

Pyrolysis affords rapid heat transfer and high thermal flux. Thin-bed or spouted configurations effect chain scission at 450–520 °C. A downstream reformer—charged with nickel catalysts or multifunctional zeolites—converts condensable vapors to light gases and elevates hydrogen yield. A metered steam co-feed increases the H₂/CO ratio and suppresses coking on active sites. Steam gasification operates at higher temperatures in vigorously mixed fluidized beds. Calcium-based sorbents (e.g., CaO) sequester CO₂ and HCl, shifting equilibria toward hydrogen. Hydrothermal processing accommodates wet, contaminated feedstocks without a discrete drying stage; hot compressed water induces bond cleavage in the presence of alkalis. Plasma polishing abates tars at very high temperature, and facilities mitigate the associated power demand through waste-heat recovery and time-of-use dispatch.

Hydrogen Output and Conditioning

Polyethylene and polypropylene contain substantial intrinsic hydrogen. Well-staged trains recover most of it as H₂ when the cracking zone holds a uniform temperature and the reformer maintains intense vapor–catalyst contact. Gasifiers raise the H₂ fraction further, particularly with steam addition and sorbent support. Hydrothermal units tolerate moisture without penalty and deliver credible yields on mixed or contaminated feed. Plasma polishing suppresses tar slip and stabilizes gas quality. Final conditioning then determines value: pressure-swing adsorption supplies high-purity hydrogen for engines or fuel cells, while tail gas furnishes heat to fired heaters or reformers to close the energy loop.

Liquid Slate and Upgrading

Pyrolysis affords rapid heat transfer and high thermal flux. Thin-bed or spouted configurations effect chain scission at 450–520 °C. A downstream reformer—charged with nickel catalysts or multifunctional zeolites—converts condensable vapors to light gases and elevates hydrogen yield. A metered steam co-feed increases the H₂/CO ratio and suppresses coking on active sites. Steam gasification operates at higher temperatures in vigorously mixed fluidized beds. Calcium-based sorbents (e.g., CaO) sequester CO₂ and HCl, shifting equilibria toward hydrogen. Hydrothermal processing accommodates wet, contaminated feedstocks without a discrete drying stage; hot compressed water induces bond cleavage in the presence of alkalis. Plasma polishing abates tars at very high temperature, and facilities mitigate the associated power demand through waste-heat recovery and time-of-use dispatch.

Carbon Solids for Lubrication

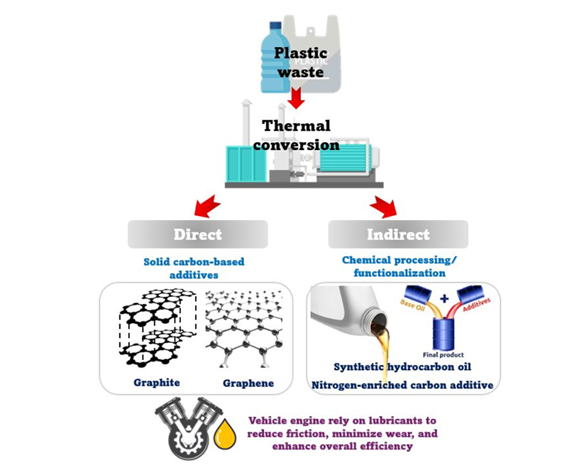

Overview of thermal conversion of plastic waste into lubricant additives and engine oil via direct and indirect pathways. Courtesy of Thermal conversion of plastic waste into fuels and lubricant additives for hydrogen internal combustion engines: A systematic review

Hydrogen combustion alters the tribological regime. Soot no longer reinforces boundary films, while water exposure increases during cold starts. Carbon nanostructures derived from plastic-origin streams can address this deficit. Flash graphitization or high-temperature finishing converts char or precursor oils into graphitized spheres and graphene-like lamellae with intrinsically low shear strength along basal planes. At sub-percent treat rates in PAO or GTL base stocks, these particles roll and slide across asperities and nucleate protective tribofilms on steel. Formulators specify particle-size distributions to match ring and liner roughness, then stabilize dispersions with tailored surfactants to prevent agglomeration and filter blockage. Activated carbons provide tunable porosity for greases, hosting functional molecules and metering oil release under load and temperature. Heteroatom doping—nitrogen, phosphorus, or boron—modulates electron density and accelerates tribofilm formation in concert with ZDDP or ashless antiwear packages, conferring advantages on DLC-coated components where conventional chemisorption pathways underperform.

Formulation Path for H₂-ICE Oils

Begin with oxidation control under water-rich conditions. Use pressurized DSC and thin-film micro-oxidation to rank base stocks and antioxidant systems at elevated temperature and defined humidity. Establish the additive backbone with hindered phenols and aryl amines that tolerate high-temperature dwell and rapid thermal transients. Address friction and wear thereafter. Set phosphorus levels to protect aftertreatment, then introduce graphitized carbon at low treat rate to reduce traction without compromising catalyst function. Verify performance on SRV, MTM, and four-ball tribometers, followed by escalation to fired single-cylinder hydrogen engines. Monitor friction mean effective pressure, inductively coupled plasma wear metals, FTIR oxidation indices, and deposit formation. During teardown, characterize tribofilms by XPS, Raman spectroscopy, and SEM to confirm lamellar coverage and thickness. Conclude with elastomer and seal compatibility assessments to guard against residual chlorine or aromatics that may bypass upgrading.

Integration, Control, and Safety

A compact facility can integrate feed preparation, a pyrolysis or gasification block, hydrogen purification, liquid upgrading, and carbon finishing within a single site. Digital twins vet set-point changes before operators adjust the DCS. Soft sensors infer tar formation and chlorine slip from temperature profiles, differential pressure, and gas composition. Mass- and energy-balance reconciliation flags drift at an early stage. Safety interlocks manage torch trips, hydrogen excursions, and acid-gas spikes via staged depressurization. Tail gas supplies process heat, and PSA off-gas stabilizes the reformer’s thermal balance. This integration reduces energy cost and increases uptime across operating campaigns.

Outlook

A single feedstock can serve two markets when quality control and process discipline remain strict. Polyolefin-rich fractions supply hydrogen for H₂ engines and help stabilize regional fuel availability. In parallel, carbon solids from the same line enhance lubricant performance under hot, lean, water-rich combustion. Plant organizations secure an additional revenue stream. Formulators gain a controllable lever on friction and wear. Fleet operators observe more consistent efficiency and durability metrics. Realizing this outcome demands rigor end-to-end: precise sorting, clean heat management, appropriate gas polishing, and validation from bench rigs through fired-engine trials.

Read the full review here: Thermal conversion of plastic waste into fuels and lubricant additives for hydrogen internal combustion engines: A systematic review.