Optimizing 3D Printing Parameters to Reduce Gear Wear

Additive manufacturing has significant advantages for lightweight gear systems, and researchers are pinpointing how to maximize their durability.

Plastic gears are a lightweight alternative to metal gears, and a common choice for precision mechanics. A lighter weight limits the load on bearings, and it also decreases the gears’ engagement noise and vibrations. These properties make plastic gears advantageous for use in applications such as laboratory equipment, where vibrational interference could impact effectiveness. Advancements in 3D printing further the potential for plastic gears. Manufacturers can print complex gear geometries with high dimensional accuracy and surface quality, using less material than traditional processes.

Optimizing Printing Parameters to Limit Wear

One disadvantage of 3D-printed plastic gears is their lower strength compared to injection molded parts. Precision mechanics applications require gears that meet stringent requirements for motion transmission. Abrasive wear can be detrimental to gear performance.

You can also read: DuPont Expands Metal Replacement Options With New Acetal Grade

In past research, polylactic acid (PLA) gears demonstrated the best wear performance for 3D-printed gears. Thus, in a study to further optimize 3D-printed gears, researchers selected PLA for the gears’ material. They printed gear samples via fused deposition modeling (FDM), each with different outer wall thicknesses (0.6, 1, and 2.4 mm). Each sample underwent mechanical experimentation, meshing with a metal reference gear. The flank of each gear tooth experienced 11,200 load cycles under a constant torque of 0.5 N·m at 0.5 RPS.

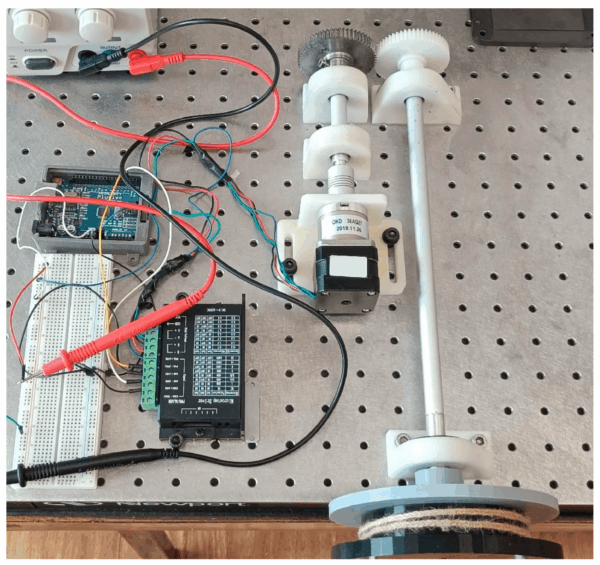

Researchers meshed the 3D-printed plastic gear samples with a metal gear before examining the wear on the gear teeth. Image courtesy of Additive Manufacturing Meets Gear Mechanics: Understanding Abrasive Wear Evolution in FDM-Printed Gears.

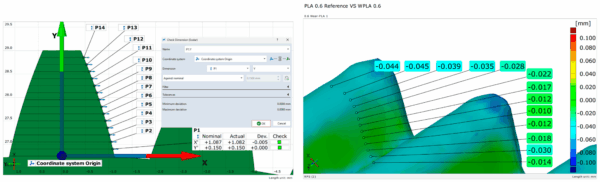

Using a GOM 3D Scanner, the researchers 3D scanned each PLA gear before and after wear testing. The GOM Inspect software allowed for the direct comparison of the gear teeth. By plotting the flank profile of a representative gear tooth, the researchers could analyze their wear.

A 3D scan coupled with GOM Inspect software provided insights into wear patterns on the gears. Image courtesy of Additive Manufacturing Meets Gear Mechanics: Understanding Abrasive Wear Evolution in FDM-Printed Gears.

Key Indicators of Wear

The geometry of the gear teeth, before and after wear testing, provided information on how wall thickness affected wear. Changes in the diameter of the gear tooth tip also indicated structural degradation. The tooth tip itself does not directly play a role in the meshing process in the function of gears. Nevertheless, reduction in tooth diameter could indicate plastic deformation of the gear. The researchers also analyzed changes in the angle of the gear teeth.

For all three gears, the tooth tip exhibited a greater degree of abrasive wear than the tooth root. This indicates that sliding velocity was the predominant influence of gear wear. The distribution of abrasive wear along the tooth profiles was non-uniform, increasing the pressure angle across the three gears. This research established a mathematical model, using experimental data, to predict gear wear. Additionally, this research confirmed the importance of full tooth infill for the durability of plastic gears.