Natural and Mineral Fillers Improve UV Stability in Rotomolded Polyethylene

Natural and mineral fillers enhance UV resistance in rotomolded polyethylene, reducing surface oxidation and improving material durability.

Rotational molding remains a preferred process for producing large, hollow polyethylene parts with uniform thickness and minimal internal stress. However, extended outdoor exposure can cause ultraviolet degradation, leading to oxidation, discoloration, and reduced mechanical performance. Engineers continuously seek new formulations that maintain durability without relying on traditional stabilizers. Therefore, integrating bio-based or mineral fillers into polyethylene represents a promising path toward sustainability and improved UV performance.

You can also read: Natural Fibers are Trending for Plastic Reinforcement.

Researchers recently investigated how natural and mineral fillers influence the long-term aging of rotomolded polyethylene. Their work compared Arundo donax L. reed fibers and ignimbrite dust—individually and combined—under accelerated UV exposure. The goal was to determine how each filler contributes to structural stability and oxidation resistance.

Designing the Composite and Testing Its Durability

The team selected a hexene-grade polyethylene resin commonly used in rotomolding applications. They prepared several composite formulations with five and ten percent filler content. Ignimbrite dust, a volcanic material rich in silica, provided inorganic reinforcement. Arundo donax L. fibers, on the other hand, offered lignocellulosic structure and antioxidant potential.

After dry blending, each mixture was processed through rotational molding into four-millimeter-thick samples. Researchers then subjected the specimens to 100, 300, and 500 hours of ultraviolet radiation in a controlled chamber. They evaluated changes using tensile testing, rheological analysis, and Fourier transform infrared spectroscopy. This combination allowed them to quantify mechanical integrity, melt behavior, and oxidation levels with precision.

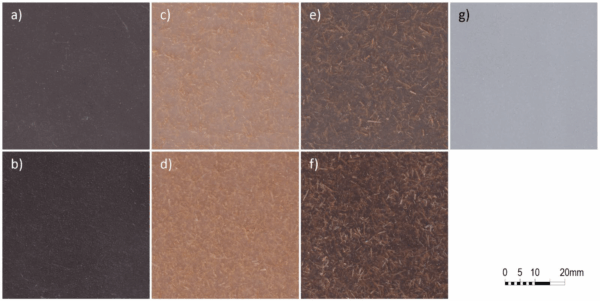

Rotomolded samples for (a) 5% ignimbrite dust, (b) 10% ignimbrite dust, (c) 5% Arundo fibers, (d) 10% Arundo fibers, (e) 5% hybrid composites: 2.5% Arundo fibers and 2.5% ignimbrite dust, (f) 10% hybrid composites: 5% Arundo fibers and 5% ignimbrite dust, and (g) neat PE. Courtesy of The Impact of Fillers on UV-Aging of Rotomolded Polyethylene Items: A Case Study on Ignimbrite Dust, Arundo donax L. Fibers, and Their Combination.

Mechanical Behavior Under UV Exposure

The results demonstrated that tensile strength and modulus remained relatively stable for all samples even after prolonged UV exposure. Because degradation affected only the surface, the overall structural integrity of thick rotomolded parts was largely preserved. However, elongation at break decreased with increasing filler content, indicating that brittleness increased slightly in filled composites.

Hybrid samples containing both ignimbrite dust and Arundo fibers showed intermediate performance, balancing stiffness and flexibility. Their tensile profiles suggested that combining mineral and natural reinforcements can minimize trade-offs between strength and ductility. These results highlight how filler synergy can create composites optimized for specific durability and performance requirements.

Monitoring Oxidation Through FTIR Analysis

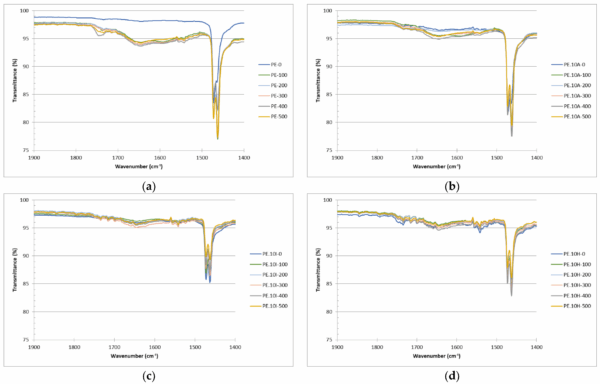

Researchers used the carbonyl index from infrared spectroscopy to monitor chemical oxidation within the polymer matrix. All materials exhibited gradual increases in oxidation with exposure time. Nevertheless, the rate of increase differed significantly depending on the filler type and concentration. Arundo fiber composites demonstrated the lowest carbonyl index, confirming their ability to act as natural antioxidants. Lignin and phenolic compounds within the fibers likely absorbed radiation and scavenged free radicals during photodegradation. Ignimbrite-filled composites displayed mixed results. At low loading levels, the mineral particles slightly improved UV stability, possibly by scattering harmful radiation. However, at higher concentrations, they accelerated oxidation, suggesting that excess mineral content concentrated heat and stress on the polymer surface. Hybrid composites maintained consistent oxidation resistance across all testing intervals, confirming that balanced filler combinations can achieve stable UV performance.

Evolution of FTIR spectra for the different UV-exposure periods: (a) neat PE, (b) PE.10A, (c) PE.10I, (d) PE.10H. Courtesy of The Impact of Fillers on UV-Aging of Rotomolded Polyethylene Items: A Case Study on Ignimbrite Dust, Arundo donax L. Fibers, and Their Combination.

Interpreting the Combined Effects of Fillers

The findings reveal that both filler type and ratio determine the overall degradation pathway of rotomolded polyethylene. Arundo fibers primarily contribute antioxidant effects, while ignimbrite dust offers partial protection and mechanical reinforcement. Their combination produces a synergistic balance between mechanical reliability and UV stability. Because oxidation remains confined to the outer surface, these composites preserve their core properties after exposure. Consequently, hybrid systems could extend the outdoor lifespan of rotomolded components without costly chemical stabilizers.

Toward Renewable and Mineral fillers in Rotational Molding

This study highlights how renewable and mineral fillers can strengthen the environmental and mechanical profile of polyethylene used in rotational molding. Using agricultural fibers and volcanic dust reduces dependence on synthetic additives while enhancing durability under sunlight. These developments align with circular economy principles, encouraging the use of regional resources and post-industrial byproducts. Future research may explore thinner parts, humidity effects, and extended exposure cycles to validate these benefits under real outdoor conditions.

By combining sustainable materials with process innovation, engineers can design rotomolded products that resist UV damage while advancing resource efficiency. Ultimately, natural and mineral fillers represent a practical step toward greener, longer-lasting polyethylene applications.