From Raincoats to Flooring: PVC’s Dual Life in Fashion and Construction

PVC extends from flexible, RF-weldable coated fabrics to rigid, load-bearing profiles in buildings and flooring systems.

Poly(vinyl chloride) (PVC) now occupies roles in transparent runway shells, welded commuter outerwear, multi-chamber façade frames, and rigid-core resilient flooring. This range reflects material science rather than branding or aesthetic positioning.

A single polymer backbone delivers optical clarity, drape, and RF-weldable seams in apparel applications. The same structure provides stiffness, impact strength, dimensional stability, UV color retention, indentation resistance, and fire performance in construction. Fashion designers and façade engineers specify different performance targets but often choose the same material system.

You can also read: Inside Materials – PVC.

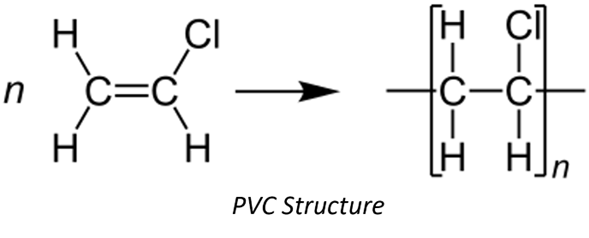

PVC Structure. Courtesy of Waxoline.

PVC: Structure, Processing, and Performance Across Applications

PVC follows a –CH₂–CHCl– repeat structure and contains about fifty-six weight percent chlorine. Because of this high chlorine content, the polymer exhibits greater bulk density and a higher limiting oxygen index than standard hydrocarbon polymers. Consequently, it also reduces flame propagation during ignition.

In addition, the polymer network remains largely amorphous during service, since extrusion, calendering, and fusion conditions rarely induce significant crystallinity or long-range order.

Glass Transition and Structural Performance

Rigid, unplasticized PVC exhibits a glass transition temperature (Tg) between 80 °C and 85 °C. This temperature range, therefore, governs handling limits, installation conditions, and structural endurance. As a result, façade profiles, window and door frames, architectural trims, and rigid plank cores for high-load flooring derive their mechanical stability directly from this transition boundary.

Plasticization and Tg Control

To regulate the glass transition temperature (Tg), process chemists adjust plasticizer content, measured in parts per hundred resin (phr). Flexible PVC for apparel and interior surfaces typically includes 25–60 phr. At these concentrations, Tg decreases to approximately −20 °C to 30 °C.

Therefore, the material gains low-temperature bend compliance, crease recovery after folding, and consistent radio-frequency weldability in coated textiles, transparent shells, hoods, and protective collars.

PVC-coated technical textiles in multiple color formulations exhibit a controlled surface texture, a weldable finish, and flexibility suitable for apparel, signage, and protective outerwear applications. Courtesy of Sioline.

Conversely, rigid PVC contains little or no plasticizer and thus retains a high Tg. This elevated Tg, in turn, ensures dimensional stability, flexural stiffness, and impact resistance in frames, façade trims, and rigid flooring cores under rolling or concentrated loads.

Thermal Stability and Fusion Control

Thermogravimetric analysis shows that PVC begins dehydrochlorination near 200–220 °C. At this point, the resin releases hydrogen chloride (HCl), which then accelerates chain scission through an autocatalytic mechanism. Consequently, this reaction causes color drift, embrittlement, and mechanical degradation.

To prevent such effects, process engineers apply strict temperature control. Production lines maintain gelation and fusion within a narrow 170–200 °C window. Within this range, particles fully coalesce and develop surface gloss while minimizing premature degradation. Thus, tight control preserves toughness, weldability, and long-term durability.

Formulation Strategy

PVC operates as a compound system rather than a single resin, and its performance depends on four main variables: resin K-value, plasticizer type and level, stabilizer chemistry, and impact modifier package.

For example, higher K-value resins yield higher molecular weight and melt strength, which improves gauge precision in calendered films and wall stability in multi-chamber window profiles. Meanwhile, flexible grades incorporate non-phthalate plasticizers—such as DEHT/DOTP, DINCH, and citrate esters—to lower Tg, enhance flexibility, and minimize odor and migration.

Additionally, calcium–zinc stabilizers capture HCl, limiting color shift and maintaining impact resistance. Acrylic, MBS, and chlorinated polyethylene modifiers enhance toughness at ambient and sub-zero temperatures. Titanium dioxide provides UV protection, whereas calcium carbonate increases core stiffness, joint stability, and creep resistance under continuous load.

Apparel: Calendered Films and Coated Textiles

Calendered PVC film forms transparent shells, high-gloss panels, and precision trims. As the molten polymer passes through stabilized roll gaps, gauge uniformity and optical clarity improve. Consequently, flexible films demonstrate Shore A hardness between 70 and 95, tensile strength of 12–20 MPa, and elongation above 200 percent—properties that enable repeated folding and deformation without whitening or fracture.

Similarly, coated textile systems apply PVC plastisol—comprising resin, plasticizer, stabilizers, pigments, and fillers—onto polyester or cotton substrates. During a controlled thermal cycle at 160–220 °C, the plastisol gels, fuses, and bonds tightly to the fiber matrix. This process, therefore, yields waterproof, abrasion-resistant laminates capable of withstanding hydrostatic pressure, flex fatigue, and mechanical stress.

In addition, technical outerwear programs replace stitching with high-frequency welding. RF welding at 13.56 or 27.12 MHz activates the C–Cl dipole, generates internal heat, and produces a continuous seam under pressure. Finally, qualification tests verify weld peel and shear strength, Martindale abrasion, low-temperature flex down to −20 °C, odor, and fogging per VDA 278.

Building: Window and Façade Profiles

Rigid PVC panel geometry on a building façade: interlocking profiles deliver dimensional stability, UV color hold, and controlled surface reflection at architectural scale. Courtesy of Canobbio.

Moreover, PVC serves as a structural material for exterior framing. Profiles must retain stiffness, gloss, color uniformity, and weld integrity despite UV exposure and temperature cycling. Typically, tensile strength ranges from 45 to 55 MPa, and flexural modulus from 2.5 to 3.2 GPa.

Testing includes heat reversion per ISO 2505 and welded-corner performance under accelerated hot–cold cycling. To achieve this performance, formulations combine suspension PVC of specified K-value with calcium–zinc stabilizers, lubricant systems, and acrylic or chlorinated polyethylene impact modifiers. Titanium dioxide ensures UV stability and color retention.

During production, twin-screw extrusion at 170–200 °C forms hollow, multi-chamber profiles. Vacuum calibration stabilizes wall geometry before cutting and welding. Afterward, durability testing measures gloss retention, ΔE* color shift, and weld integrity after xenon-arc or UV-A exposure.

Flooring: Rigid-Core Plank Systems

PVC flooring goes down as a single layer and locks the room in place — wood look on the surface, engineered vinyl core underneath. Courtesy of Goldstab.

PVC also anchors resilient flooring, including luxury vinyl tile (LVT) and rigid-core planks. Each plank integrates a transparent wear layer, a printed décor film—wood, stone, or terrazzo—and a protective topcoat over a reinforced PVC core.

Core design diverges along two paths. Foamed PVC uses blowing agents and process aids to form closed-cell structures that reduce mass, enhance acoustic damping, and absorb minor subfloor irregularities. In contrast, mineral-filled rigid cores employ high calcium carbonate loading to raise indentation resistance, reinforce click-joint rigidity, and maintain dimensional stability under thermal fluctuations near glazing or radiant heating.

Consequently, specifiers in healthcare, education, and retail environments evaluate parameters such as residual indentation (ASTM F1914), static load (F970), dimensional stability (ISO 23999), Taber abrasion, and stain resistance to disinfectants. Many projects restrict indentation to ≤ 0.20 mm after the defined load and dwell. Meanwhile, suppliers document VOC performance, recycled-content declarations, and rolling-load compliance.

Performance Requirements Across Industries

PVC spans applications from transparent shells and welded outerwear to façade profiles and rigid-core flooring systems. Development programs across apparel, construction, and interior design treat it as a configurable material platform, not a fixed formulation.

Ultimately, apparel designers require RF-weldable films with reliable cold-flex performance and chemical resistance. In contrast, building teams prioritize modulus stability, weld precision, and UV durability. At the same time, flooring specialists emphasize rigid cores that resist indentation, preserve joint integrity, and comply with indoor air-quality standards.

In summary, PVC remains a versatile engineering polymer that bridges flexibility and rigidity through controlled chemistry, formulation precision, and thermal discipline—serving both creative and structural needs across industries.