Cold Sintering Advances Polymer–Ceramic Composite Manufacturing

An emerging technology, cold sintering, promises breakthroughs in the production of polymer-ceramic composites.

What is Cold Sintering?

Cold sintering is a process for densifying ceramics at extremely low temperatures. While ceramic sintering usually occurs at temperatures of 1,000-1,500 °C, cold sintering brings this temperature down to 100-200 °C. This is achieved through uniaxial pressure and a transient solvent, applied to a powdered ceramic. This method of sintering is drawing attention of researchers, with a variety of novel applications. One such application is plastic-ceramic composites, a long-standing challenge for materials engineers due to the disparity of their processing temperatures.

You can also read: Hybridizing Epoxy Composites with Egg Shell Powder.

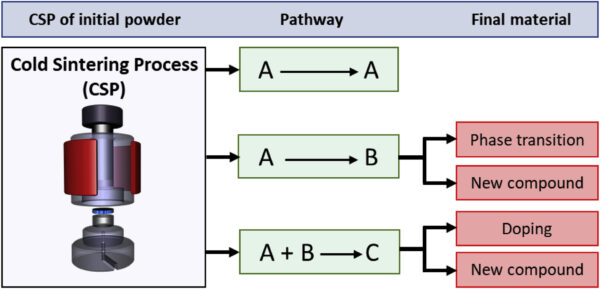

The choice of powdered material used for cold sintering determines chemical composition and crystallography. Image courtesy of Roadmap for densification in cold sintering: Chemical pathways.

Polymers Integrated in the Process

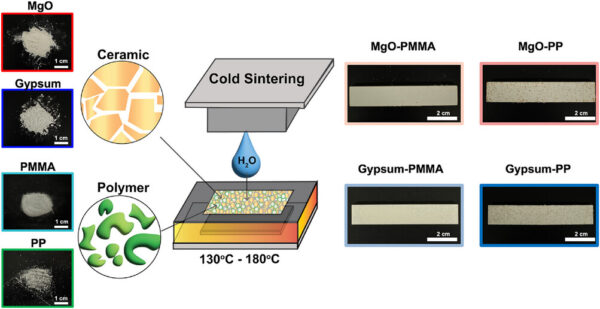

Cold sintering therefore offers new possibilities for fabricating polymer composites with enhanced functionalities, effectively combining the properties of ceramics and polymers. In particular, a 2025 study demonstrated this potential by fabricating a composite using polypropylene (PP) and poly(methyl methacrylate) (PMMA). To achieve this, researchers selected gypsum (CaSO₄•2H₂O) and magnesium oxide (MgO) as the ceramic components. Initially, they used a cryomill to form 250–500 µm PP particles and, subsequently, applied a sieve to fractionate the PMMA powder.

Afterward, the researchers mixed and ground the ceramic and polymer powders with a mortar and pestle. Then, they moistened the mixture with water to facilitate densification. Finally, these samples underwent isothermal cold sintering at the target temperature range of 130–180 °C under 100 MPa of pressure for one hour, producing uniform polymer–ceramic composites ready for further characterization.

Researchers produced MgO-PMMA, MgO-PP, gypsum-PMMA, and gypsum-PP composites using cold sintering. Image courtesy of Co-continuous composites from cold sintering.

This study brought particular attention to the influence of material choice on the composite. The PMMA composites demonstrated a more uniform, homogeneous mixing of polymer and ceramic phases. The PP composites exhibited clear phase boundaries between then two. These results occurred because PP does not have any functional groups that strongly interact with gypsum or MgO. By controlling for these material interactions, researchers can achieve better composite results.

Implications for Future Research

Polymer-ceramic composites are in the early stages of research and development. Cold sintering enables the creation of unique composites. As research continues, more applications for these composites are likely to emerge.

Researchers at Pennsylvania State University investigated one such application in a 2024 study. Using cold sintering, they upcycled PP waste and construction waste into structural materials. The ceramic used for this study was CaSO4, the main component in gypsum drywall. They found that, after cold sintering, the ceramic properties dominate the composite’s performance. Mechanical performance of the composite using virgin versus recycled PP showed minimal variation. This implies that this process is well-suited for plastic waste. Cold sintering can produce tough composites, regardless of the source of PP. This method has a significantly lower environmental impact than commonly used building materials.