Stress Control in Carbon Fiber Aerospace Components

Carbon Fiber Reinforced Plastic (CFRP) is replacing metal in many aerospace applications, and controlling internal stresses is necessary for performance.

The lifespan, stealth, and maneuverability of modern aerospace products, with load bearing components made form CFRP, have improved significantly.

Recent technological advancements have allowed the adoption of Carbon Fiber Reinforced Plastic (CFRP) to replace metal in certain aerospace products. CFRP offers high strength, hardness, and specific density, making it a valuable material for lightweight, high-performance applications. When working with large CRFP parts, it is necessary to consider the unique characteristics of the material.

You can also read: Composite 3D Printing in Aerospace and Robotics

Complex Stresses Affect CRFP During Clamping

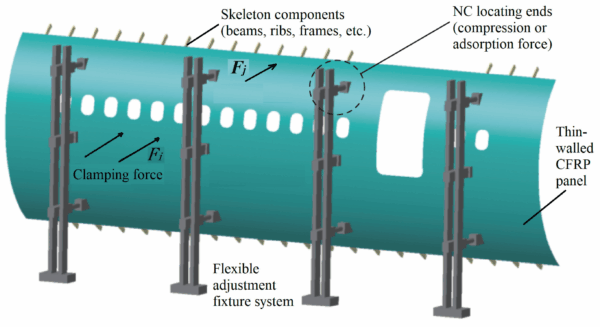

In the aerospace industry, manufacturers shape CRFP parts using forced clamping. This technique limits assembly errors and can help maintain geometric consistency during manufacturing. With high geometric precision, there is less need for padding and surface grinding at the interfaces of parts. Due to the high brittleness of CRFP, forced clamping can also introduce internal stresses. Because CRFP is anisotropic, part manufacturers must also consider the direction, magnitude, and layout of clamping and shape correlation forces. Additionally, the uneven bonding layer strengths within the composite can lead to internal stresses.

Forced clamping involves the application of tension or compression forces at the ends of Computer Numerical Control (CNC) positioners. Courtesy of Assembly Quality Control Technologies in Forced Clamping and Compensation Processes for Large and Integrated Aeronautical Composite Structures.

Assuring Quality in CRFP Parts

Researchers have found various strategies to mitigate the stresses resultant from forced clamping. These key technologies can help manufacturers achieve improvements in assembly quality.

- Setting Force Limits: When applied force exceeds the allowable range, CFRP parts may become damaged or destroyed. Precise control of clamping force can prevent shape deviation, excessive internal stress, and structural damage. Manufacturers can find appropriate force limits by developing an optimization model and comparing simulation data to actual measurement data.

- Reducing Geometric Mating Gaps: The geometric gap thickness between curved parts directly affects strength and performance. When manufacturers reduce mating gaps using forced clamping, internal assembly stresses between these mating surfaces increase. 3D scanning and mechanical simulation can help identify areas to prioritize as clamping points. Then, modeling can provide insights into how to precisely adjust clamping to meet stress requirements without damaging parts.

- Predicting Internal Stress and Damage Evolution: Finite element simulation, fundamental joining experiments, and theoretical analysis of damage can aid in predicting stress and damage propagation. Real-time data monitoring can provide feedback during experimentation.

- Reverse Optimizing Clamping Parameters: Using reverse optimization, manufacturers can better understand the complex relationships between the parameters at play during forced clamping. Artificial intelligence, mathematical models, and finite element methods can aid in inverse optimization calculations.

- Measuring Precise Stress and Damage: Internal assembly stresses may be invisible to the naked eye but can cause catastrophic damage to parts. Tools such as an acoustic emission system, ultrasonic probes, and digital image correlation can help quickly and accurately pinpoint damage.

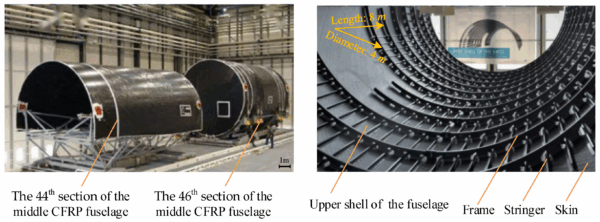

Quality, consistency, and mechanical performance are vital when manufacturing large CRFP parts for aerospace applications. Courtesy of Assembly Quality Control Technologies in Forced Clamping and Compensation Processes for Large and Integrated Aeronautical Composite Structures.

These approaches can help ensure consistency and control during the forced clamping process. Aerospace product design and construction have experienced significant technological advances in recent years. Future avenues of research may expand the optimization of forced clamping by developing a deeper understanding of parameter relationships