Recycled Polyurethane Gives New Life to Insulating Mortars

A new mortar made with recycled polyurethane foam offers lightweight thermal insulation for floors and roofs, advancing circular construction.

Incorporating sustainable materials in construction applications is of growing interest in recent years. PU rigid waste, for example, can replace aggregates and sand in cements. The low density of PU allows for lighter structural elements. A recent study has found another use for recycled PU—a lightweight, insulating mortar made from rigid PU foam. Innovative approaches to sustainable building materials helps divert plastic from landfills while conserving the natural resources used in construction.

You can also read: Building Blocks Made of Plastics Waste Spur Affordable Construction.

Just Add Water

In this study, researchers used rigid PU waste sourced from a sandwich panel manufacturer to develop the mortar. After optimization of the mortar, they collected rigid PU waste from a variety of sources, including demolition and refrigeration waste. They processed this PU waste through a specially designed granulator to create 0-10 mm particles before preparing the mortar mixes. The curing process lasted 28 days, which is standard for mortar.

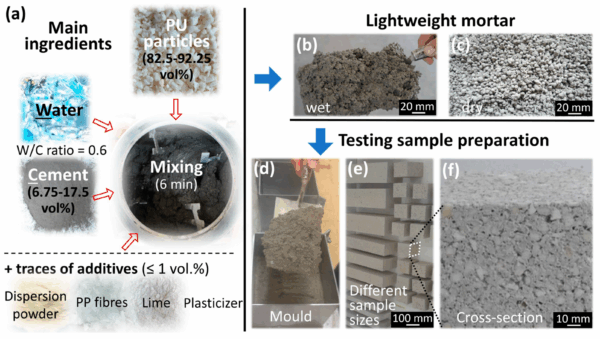

The mortar mix contained water, PU particles, cement, and trace additives. Courtesy of A New Recycling Technology to Produce Premixed Thermal Insulating Mortars from Polyurethane Waste Foams.

The proportion of PU was the primary influence of the mortar’s bulk density, compressive strength, and thermal conductivity. PU particle size also plays a role in these characteristics. Previous studies primarily used smaller particles (<4 mm), but larger particles offer several advantages. These large particles trap more air due to their lower surface area: volume ratio and cellular structure. This leads to a reduction in thermal conductivity. Larger particles are conducive to an overall lower mortar density. In this study, researchers developed a material for floor and roof insulation applications. A low density is appropriate for lightweight, non-load-bearing applications, such as this. Additionally, large particles lead to less water absorption, improving workability. With a more uniform void distribution, they exhibit better acoustic insulation and are more resistant to environmental stress.

After rigorous analysis, the optimized lightweight mortar had the following ratio of components:

| PU (vol%) | 92.25 |

| Cement (vol%) | 6.75 (W/C ratio 0.6) |

| Lime (vol%) | ~1 |

| Dispersion Powder (vol%) | 0.00055 |

| Plasticizer (vol%) | 0.00055 |

| Polypropylene Fibers (vol%) | 0.00028 |

Scaling Up Production

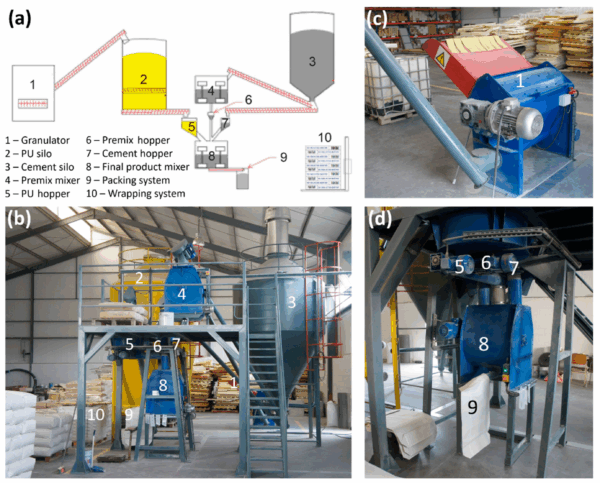

The researchers then designed a prototype mortar production system, with a capacity of 1,500 L of mortar per hour. With two adjacent silos filled with PU and cement, the system mixes the mortar components and packs it into bags. To validate the production system, the researchers filled ten 75 L bags, randomly collecting them from different production batches. During a 12-month testing period, the mortar did not exhibit signs of cracking, shrinkage, or mechanical failure.

The adjacent PU (2) and cement (3) silos feed the two main ingredients into the mixture. Courtesy of A New Recycling Technology to Produce Premixed Thermal Insulating Mortars from Polyurethane Waste Foams.

This study showed novel mortar using recycled PU foam from development to large-scale production. The production system developed in this study can package the mortar in paper bags. Then, on site, workers can mix the mortar with water and can use it immediately. With a light density, this material is ideal for floor insulation. This new material demonstrates an exciting example of another sustainable building material, supporting circularity in the plastic economy.