Read Your Material Datasheet to Cut Molding Costs and Defects

Learn to read material datasheets—MFI, rheology, HDT, modulus, shrinkage and CTE—to cut injection molding cycle time and avoid warpage and rework.

Selecting a resin for injection molding is a multidimensional decision. Flow isn’t only about MFI/MFR; several other properties on the datasheet directly influence cycle time, shrinkage, and warpage.

You can also read: The Impact of Pigments on Plastic Dimensional Stability.

Data That Drives Cycle Time

- Flow behavior (beyond MFI):

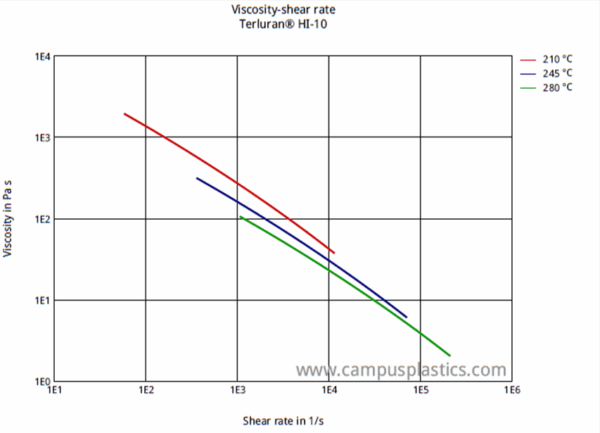

MFI/MFR gives a quick feel for fillability at low, fixed shear. Injection molding runs at much higher shear rates, so confirm flow with rheology curves (viscosity vs. shear rate) at your processing temperature. Look for shear-thinning: viscosity should drop noticeably as the shear rate rises, which supports faster fills at lower pressures. - Shear sensitivity:

If the datasheet provides a power-law index (n) or viscosity ratio, use it to compare shear dependence: a lower n (more shear-thinning) generally fills easier and can reduce injection pressure and clamp force. - Thermal stiffness for earlier ejection:

Use HDT (Heat Deflection Temperature) as a proxy for when parts retain rigidity under load during demolding. A higher HDT typically allows shorter cooling and earlier ejection (all else equal). When available, also review Vicat softening or Tg (for amorphous polymers) to understand the safe ejection window.

The rheological curves describe how viscosity drops in dependance of both temperature and shear rate. A larger drop within higher shear rates demonstrates that larger injection speed will reduce the resistance to flow. Courtesy of Campus Plastics.

Data That Protects Part Quality

- Rigidity and stress tolerance:

Young’s (tensile) modulus and flexural modulus indicate how much a part resists deformation. Higher modulus resins better tolerate internal molded-in stresses, reducing the tendency to warp after ejection. - Shrinkage and warpage tendencies:

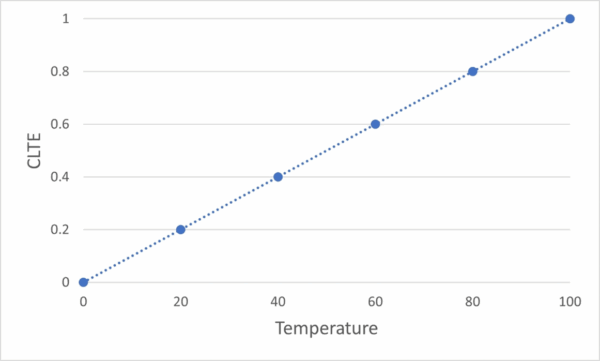

Check both mold shrinkage values (often given flow vs. cross-flow) and the coefficient of linear thermal expansion (CLTE/CTE).

Higher CLTE → greater size change as the part cools, which can amplify warpage—especially with variable wall thickness where thick sections “pull” thin walls.

Anisotropy matters. Filled resins (e.g., glass fiber) often list directional shrinkage and CTE; differences between directions drive curling or twisting.

If available, PVT or crystallinity notes can hint at how packing, mold temperature, and cooling rate will shift final dimensions.

The coefficient of linear thermal expansion measures how the part’s dimensions change with temperature. Selecting a material with a lower coefficient will lead to lower shrinkage. Courtesy of Specialchem.

Put It Together—What to Verify on the Datasheet

MFI/MFR (reporting temperature & load) and rheology/viscosity curves at molding temps.

Shear sensitivity indicator (e.g., power-law index n).

HDT (note the load: 0.455 or 1.82 MPa), plus Vicat/Tg when listed.

Tensile/Flexural modulus (rigidity baseline).

Mold shrinkage (flow vs. cross-flow) and CLTE (directional if filled).

For filled/engineering resins: filler type/content, drying requirements (e.g., PA), and any annealing or conditioning notes that affect dimensions.

Bottom line: Don’t stop at MFI. Pair rheology (for flow and cycle time) with thermal stiffness (for earlier ejection) and dimensional data (shrinkage/CLTE, anisotropy) to minimize pressure, cooling time, scrap, and rework—and to keep shrinkage and warpage in check.