On Track to Better Performance: Composites for Railroad Ties

Recycled plastic composites are transforming railroad ties, offering higher strength, longer life, and reduced train wear compared to wood or concrete.

Railroad ties, also called crossties or railway sleepers, are the rectangular supports typically found beneath railroad tracks. These ties must bear the huge pressure of passing trains, transmitting pressure from the rails to the track bed. Typically, traditional railroad ties are wooden. Wooden ties are highly perishable, have poor elasticity, and have a high replacement cost. A new material with sufficient flexural strength, compression strength, and hardness could serve as an alternative to wooden ties. Additionally, railroad ties must have flame-retardant and insulating properties.

Other materials, such as steel or concrete, have their own drawbacks. Steel ties are costly and susceptible to corrosion and vibrations. With high hardness and poor elasticity, concrete ties can cause wear to trains and limit their speed. Concrete ties are also prone to cracking over time, resulting in costly repairs.

Composite railroad ties have recently been gaining traction as a replacement for traditional wooden ties. Composite ties can overcome the drawbacks of wood, steel, and concrete, providing better performance for railway applications. These composites, comprised of recycled plastic waste, can improve rigidity, load-bearing capacity, and lifetime while reducing wear on ballasts.

You can also read: Infrastructure Could Play a Big Role in Boosting Plastics Recycling

Case Study: Designing for the Chinese Railway System

While concrete sleepers remain common in China, there is a growing demand to replace them with composites that meet modern performance requirements. Nevertheless, recycled-material composites have not yet fully satisfied the Chinese railway system’s stringent mechanical and safety standards. To address this challenge, researchers in China developed a new composite railroad tie formulation based on high-density polyethylene (HDPE)—a widely recycled plastic known for its balance of strength and processability.

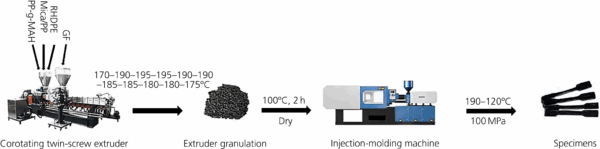

Researchers used a corotating twin-screw extruder and injection molding machine to manufacture sample composite ties. Figure courtesy of Composite materials using recycled high-density polyethylene plastic for railway sleepers.

During development, researchers designed two material groups—Group A and Group B—to compare performance and compatibility. In both cases, polypropylene (PP)-grafted maleic anhydride (PP-g-MAH) functioned as a compatibilizer, enhancing interfacial adhesion between the polymer matrix and reinforcing fibers.

Group A composites included recycled HDPE, glass fiber (GF), mica, and the compatibilizer.

Group B composites included recycled HDPE, GF, PP, and the compatibilizer.

Each group was further subdivided into six samples with varied component ratios to identify optimal formulations.

Among all twelve samples, sample B6 demonstrated the best overall performance. Its composition was as follows:

| Component | Content (%) |

|---|---|

| Glass Fiber (GF) | 62.6 |

| Recycled HDPE (RHDPE) | 14.5 |

| Mica | – |

| PP-g-MAH | 3.0 |

| Polypropylene (PP) | 20.0 |

Results and Implications

After extensive testing, the composite samples exhibited significantly higher flexural and compressive strength than traditional wooden or concrete ties. The inclusion of glass fiber proved crucial, as it enhanced the material’s flexural modulus, tensile strength, and overall rigidity. Furthermore, the optimized composite satisfied cost-efficiency requirements while eliminating secondary pollution, thanks to its recycled content and clean processing profile.

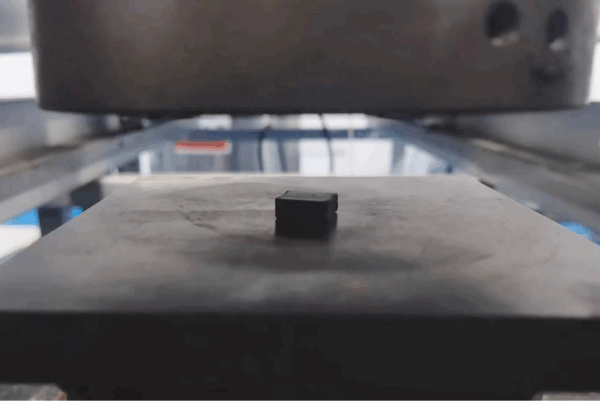

Each sample underwent compressive testing on tensile test equipment. Figure courtesy of Composite materials using recycled high-density polyethylene plastic for railway sleepers.

Therefore, this research demonstrates the viability of recycled plastic composites as next-generation materials for railway infrastructure. By integrating recycled HDPE with reinforcements such as glass fiber and PP-g-MAH, engineers can design components that extend service life, minimize maintenance, and reduce environmental impact. As adoption expands, such composite ties could help countries like China—and others with aging rail systems—replace concrete sleepers with sustainable, high-performance alternatives.

Was testing conducted over the expected service temperature range? And just the ambient temp but rail ties will be in the sun and I expect carbon black would be added for UV protection but that would mean in the sun they would heat up significantly above the ambient air temp. Does CTE have effect on rail position relative to the wheels of the train cars? I think this could be a good start but I imagine further testing is required.