Novel Waterfall Cooling Channel for Molding

A novel waterfall cooling channel reduces pressure drop by 56% and boosts cooling efficiency in injection molding compared to conventional designs.

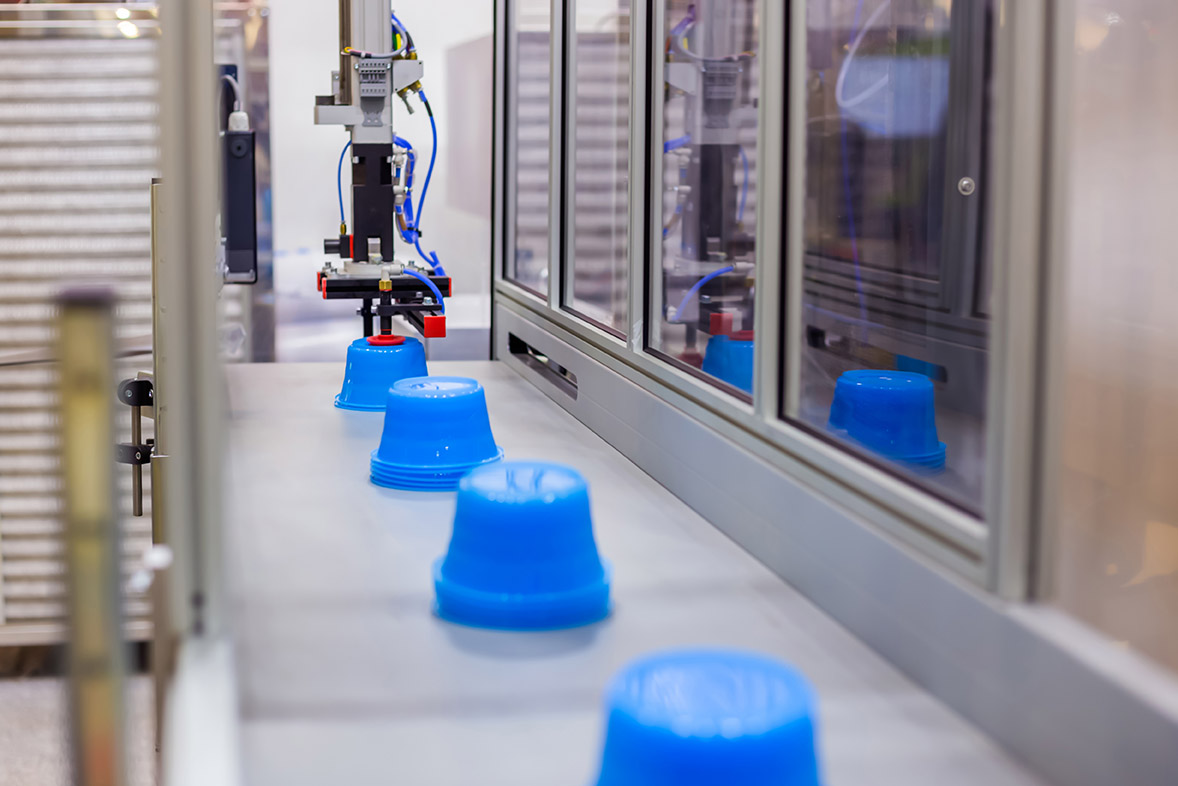

Blow molding and injection molding commonly use conforming cooling channels (CCCs). CCCs conform to the shape of the molded product and optimize heat dissipation during the cooling process. During cooling using CCCs, the injected medium experiences a significant pressure drop along the cooling channels.

You can also read: 3 Tips for Cooling Design in Injection Molding.

This is a significant drawback; the change in pressure can cause a disruption in the uniformity of the flow. Circulating the coolant to overcome the pressure drop requires greater pumping power, and thus, more energy consumption. To overcome this issue, researchers developed a waterfall cooling channel (WCC) that reduced pressure drop by 56%.

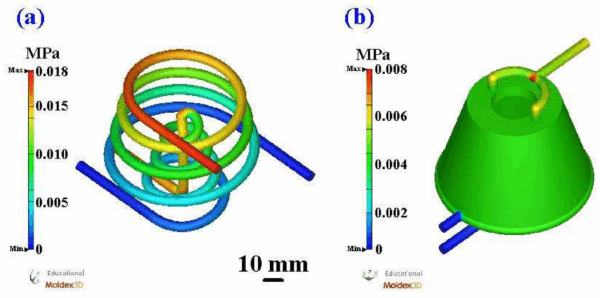

During simulation, the WCC exhibited more uniform pressure than the conventional CCC. Courtesy of Development of a Silicone Rubber Mold with an Innovative Waterfall Cooling Channel.

Fountain Flow for Uniform Cooling

The WCC consists of two distinct parts: a core and a cavity, which surround the molded product. The cooling liquid flows through the WCC and across the surface of the molded product. The WCC is a parallel water channel, thus, water can flow from the outlet without significant pressure. The CCC, in comparison, is comprised of a series of water channels. Thus, it requires more pressure at the water inlet to allow water to exit the outlet. This design change leads to significantly lower changes in pressure during cooling.

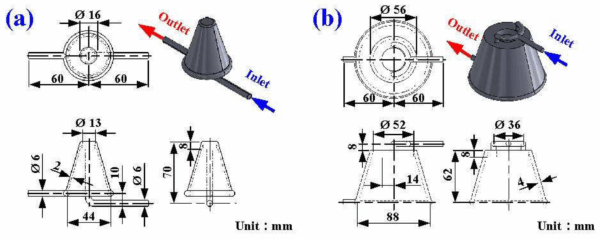

The WCC leverages fountain flow through a core (a) and cavity (b) to reduce pressure drop during cooling. Courtesy of Development of a Silicone Rubber Mold with an Innovative Waterfall Cooling Channel.

To compare the two cooling systems, researchers designed a CCC and WCC for the injection molding of a water cup. They used Moldex3D software to optimize the design of the cooling channels. Then, the researchers 3D-printed the channels using polyvinyl butyral (PVB). 3D printing offers the ability to quickly fabricate complex geometries, such as these cooling channels. To create a mold, they poured silicone rubber around the PVB channels. Then, they dissolved the PVB with an industrial alcohol solution.

Quantifiable Results of More Efficient Cooling

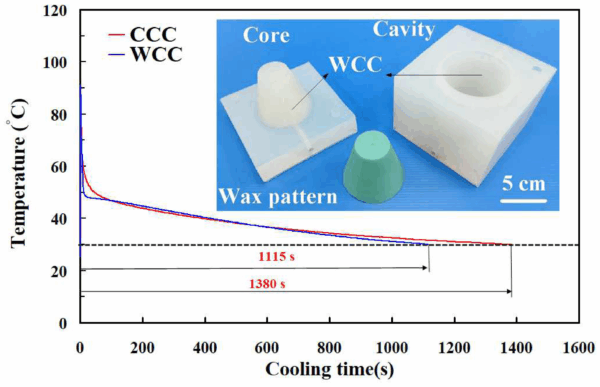

The researchers used a low-pressure wax injection molding machine to manufacture the water cup and compare the two cooling systems. Compared to the CCC, the WCC:

- Reduced the pressure drop by 56%

- Increased the cooling efficiency by approximately 17.47%

- Had a cooling efficiency close to 50%

Using the WCC reduced the cooling time of the injection molded wax water cup. Courtesy of Development of a Silicone Rubber Mold with an Innovative Waterfall Cooling Channel.

Compared to the CCC, the WCC maintains uniform and steady cooling when incorporated into an injection mold. This novel cooling approach can reduce cooling times and, thus, production costs in certain applications, such as investment casting.