Latin America Advances Circularity Without a Global Treaty

Colombia and Latin America advance circular plastics with eco-design, R&D, and regulation, proving circularity moves forward without a global treaty.

A Global Treaty Without Consensus

The Geneva talks on a Global Plastics Treaty (August 5–15) ended without agreement. Producer countries, including the United States, India, and Gulf nations, blocked proposals to curb virgin plastic production.

Meanwhile, more than 100 nations in the High Ambition Coalition pushed for a broader vision regulating the entire life cycle from manufacturing to final disposal.

The talks concluded with an unfinished text, yet revealed clear trends that will shape the plastics industry soon.

You can also read: SPE – A Key Observer in the Global Plastics Treaty.

“This Isn’t Stopping”

Daniel Mitchell, president of Acoplásticos — the Colombian Association of Plastics Industries — stresses that the lack of consensus does not stop progress.

Daniel Mitchell, president of Acoplásticos — the Colombian Association of Plastics Industries. Courtesy of Acoplasticos.

“Plastic pollution is a global issue. Everyone wants solutions. The treaty proves that, despite differences between countries. What’s clear is this isn’t stopping,” he says.

Mitchell believes that national and regional regulations will continue to advance even without a global deal. He highlights the decisive role of R&D in driving circularity.

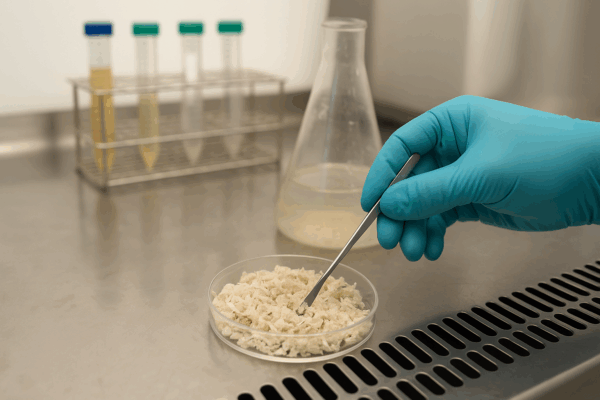

R&D: The Frontline of Change

For Mitchell, the greatest challenges now rest with research and development teams.

“Labs and development centers must accelerate. Advanced chemical recycling resins and additives that improve recycled material performance are critical. R&D will determine if circularity competes on both price and quality,” he explains.

Labs and development centers must accelerate. Image generated by AI.

Hurdles include maintaining transparency, safety, and strength in recycled polymers, fixing color and odor issues in packaging, and creating safe food-contact solutions.

The Eco-Design Challenge

Product redesign also demands attention. “Eco-design is essential. We need packaging and parts with higher recycled content, easy reuse, and simple separation. Without demand for these products, the circular economy will not succeed,” Mitchell notes.

Technical teams already test lighter bottles, single-material structures, and multilayer designs that improve recyclability and reuse.

Advanced Recycling: Promise and Cost

In Geneva, delegates also debated chemical traceability through digital product passports. For R&D, this means mapping additives and ensuring transparency across every formulation.

“Mechanical and chemical recycling must expand. The problem is cost. Today, it remains more expensive than virgin polymer,” Mitchell warns.

Regulation can close this gap. In Colombia, mandatory PET recycling targets in bottles already drive demand, pushing R&D to deliver more competitive formulas.

Extended Producer Responsibility

Extended Producer Responsibility (EPR) also entered the negotiations. Mitchell views it as a direct driver for innovation.

“Regulation is key. Without binding targets, the market always chooses the cheapest option, and that blocks circularity. With extended responsibility, design must include end-of-life costs from the start.”

Regulation is key. Without binding targets, the market always chooses the cheapest option, and that blocks circularity. Courtesy of Acoplasticos.

Innovation Across the Chain

The frontline of circularity remains in the lab, where chemistry and engineering rewrite plastic’s life cycle. (Image created with AI)

Mitchell argues that innovation must reach every link in the chain. “AI-driven sorting, chemical recycling, advanced separation technologies — innovation is transversal. If one link fails, the circle breaks.”

Even without a global treaty, the circular economy is already a market and technical demand. Mitchell concludes:

“R&D teams that act now will not only meet future regulations. They will also build reputation, attract investment, and win market trust.”