Designing Polymeric Composites at the Voxel Scale with Multi-Material Jetting

Voxel-scale multi-material jetting lets engineers design polymer composites with tunable stiffness, strength, and toughness directly through digital control.

Additive manufacturing has changed how engineers work with polymers. It reduces waste, supports complex shapes, and opens a new way to design composites. Multi-material jetting (MMJ) prints at the voxel scale, about 14 microns, so engineers can place different materials with precision that other methods cannot reach. Instead of switching filaments, powders, or resin layers, MMJ deposits tiny droplets of photopolymer that cure under ultraviolet light. This process creates both rigid and flexible regions in one part and enables composites that combine strength, stiffness, and toughness beyond what traditional laminates allow.

You can also read: Composite 3D Printing in Aerospace and Robotics

Researchers at Duke University examined this potential by comparing four approaches: layered composites, sandwich structures, preset digital materials (DMs), and custom voxel-scale DMs. Their analysis showed that voxel-level distributions extend the mechanical property range well beyond preset or layered options, especially for modulus, strength, and toughness. The study demonstrates how voxel-scale design turns MMJ into a tool not only for shaping parts but also for tailoring their mechanical behavior.

From Conventional Layering to Voxel-Resolved Deposition

Earlier multi-material additive manufacturing processes provided some compositional flexibility yet remained constrained by coarse characteristic length scales that limited both gradient resolution and interfacial integrity. Fused filament fabrication required nozzle switching or sequential extrusion of thermoplastic filaments, which introduced thermal cycling and poor bonding at material interfaces. Selective laser sintering depended on powder mixtures, where particle size and packing density imposed strict boundaries on achievable transitions. Digital light projection enabled resin combinations only at discrete layer boundaries, precluding intralayer heterogeneity. None of these methods permitted fine-scale compositional control within a single cross-section.

Multi-material jetting introduced voxel-resolved deposition, in which hundreds of nozzles dispense photopolymer droplets that cure under ultraviolet light, producing sharply defined domains with interpenetrating rigid and compliant phases. Commercial implementations such as Stratasys PolyJet illustrate this capability, combining high-modulus, brittle Vero formulations with ductile, elastomeric Agilus resins, and thus creating a tunable design space that spans extremes from brittle-strong to soft-flexible behavior.

Experimental Framework

The Duke study fabricated ASTM Type V dogbone specimens in four categories. Multilayer composites alternated rigid and soft layers while keeping volume ratios constant. Sandwich composites positioned one material at the core with the other as skins, varying core thickness. Preset digital materials used Stratasys software to generate proprietary blends. Custom digital materials employed the Digital Material Creator to define voxel-level distributions with rigid fractions ranging from 10 to 90 percent.

Each specimen underwent uniaxial tensile testing, producing stress–strain curves for analysis. Finite element simulations complemented the experiments, allowing the team to interpret fracture modes and stress transfer within different geometries.

Performance of Layered and Sandwich Composites

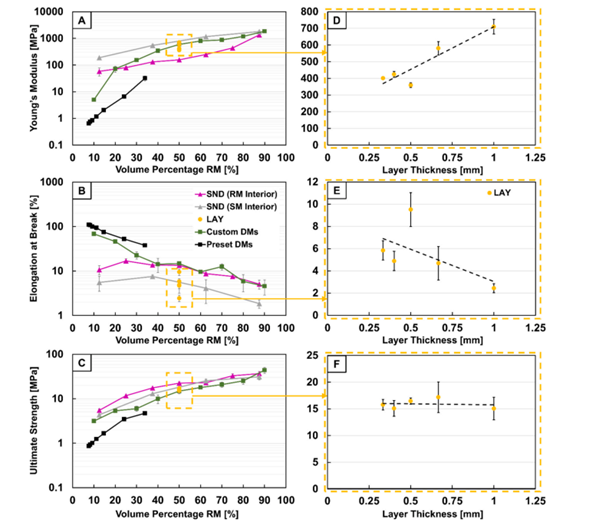

Mechanical property trends of layered (LAY), sandwich (SND), and custom digital material (DM) composites. Panels A–C show how Young’s modulus, elongation at break, and ultimate strength vary with rigid material fraction. Panels D–F highlight the effect of layer thickness on the same properties for 50–50 LAY composites. Courtesy of Structure-performance relationships of multi-material jetting polymeric composites designed at the voxel scale: Distribution and composition effects.

Layered specimens displayed modest changes with layer thickness. Young’s modulus rose slightly as layers thickened, while elongation decreased, and strength remained stable. Failure moved through alternating layers, beginning at the outer rigid domains and progressing inward. Strong bonding across interfaces prevented delamination, which often plagues traditional laminated composites.

Sandwich specimens showed sharper contrasts. When rigid material occupied the core, modulus and strength increased as its thickness grew, while elongation dropped. Soft cores produced the opposite trend. Specimens with rigid cores and soft skins elongated more than those with soft cores and rigid skins. Grip-induced shear deformation explained this outcome: soft skins absorbed part of the applied load before transferring stress to the core. Simulations confirmed the effect.

Digital Materials and Tunability

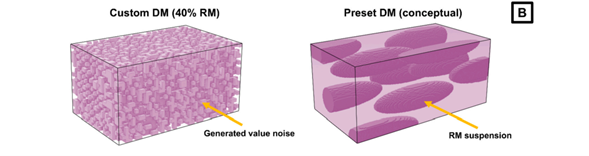

A zoomed-in view of the voxel distribution pattern of a custom DM and conceptual preset DM. Courtesy of Structure-performance relationships of multi-material jetting polymeric composites designed at the voxel scale: Distribution and composition effects.

Preset digital materials offered convenience but limited property ranges. Their microstructures, formed by ellipsoidal inclusions, restricted rigid content to about one-third of total volume. As a result, preset DMs delivered moderate stiffness and strength but broad elongation.

Custom digital materials expanded the possibilities. By distributing voxels of rigid and soft polymers in controlled ratios, researchers achieved moduli from 5 MPa up to nearly 1900 MPa, strengths up to 44 MPa, and toughness values almost twice those of layered or preset composites. The finer voxel-scale distribution created higher interfacial area, which improved stress transfer and increased stiffness, while the small-scale mixing reduced critical particle size effects. Preset DMs still showed higher elongation because their continuous regions limited stress concentrations, but custom DMs clearly provided the broadest and most useful property range.

Modeling and Fracture Analysis

The team developed a multilayer deformation model that captured sequential layer failure and shear transfer between rigid and soft regions. Simulations aligned with experimental results, showing outer rigid layers failing first and shifting stress inward. Microscopy revealed tearing of soft layers at interfaces, consistent with stress transfer across well-bonded boundaries. This combination of modeling and morphology provided a framework for predicting behavior of voxel-defined composites beyond the tested set.

Implications for Polymer Engineering

Voxel-scale MMJ enables engineers to design composites as digital materials rather than as stacked layers. Instead of choosing one polymer and then adapting geometry, the process begins with a performance goal—stiffness, strength, or toughness—and continues by defining voxel distributions that deliver the required response. This shift opens applications such as medical models that reproduce tissue gradients, consumer products with hinges integrated into rigid housings, and structural components with controlled stiffness variation. The same approach can extend to systems with three or more polymers, smoother gradients, and lattice structures with voxel-level tuning.

Expanding the Design Space

The study demonstrates that MMJ, when combined with voxel-level design, moves additive manufacturing beyond shape and into property-driven engineering. Custom digital materials extend performance ranges beyond layered and preset options, making stiffness, strength, and toughness adjustable through software rather than secondary processing. For polymer engineers, this represents a new paradigm: designing composites like digital images, voxel by voxel, with each droplet defining not only geometry but also performance.

Read the full article here: Structure-performance relationships of multi-material jetting polymeric composites designed at the voxel scale: Distribution and composition effects