TPE Foam Shows Potential in Oil Cleanup

A novel material helps bypass the limitations of traditional materials used for oil spill cleanup.

Polymeric foams commonly serve as a material used to clean oil spills in water. These low-density, highly porous foams can comprise polyurethane, polylactic acid, polypropylene, and polystyrene. Small cavities within the foam capture and retain oil, and these foams work swiftly and efficiently. Still, polymeric foams have a significant limitation: leakage can occur if the amount of oil exceeds their saturation point. This can lead to complications when remediating oil plumes in groundwater. Contamination in groundwater is difficult to track and can spread to considerable distances depending on the area’s hydrology. Therefore, containing these spills is of upmost importance.

Overcoming the Limitations of Traditional Foams

Researchers developed a novel, porous styrene-ethylene-butylene-styrene (SEBS) foam as an alternative to traditional polymeric foams. SEBS is a thermoplastic elastomer (TPE) copolymer with distinct properties that prevent oil from spreading. Styrene provides hardness and rigidity and tends to dissolve in oil less than ethylene-butylene. Ethylene-butylene, which provides flexibility and elasticity, readily dissolves in oil. Thus, when exposed to oil, SEBS forms a gel structure.

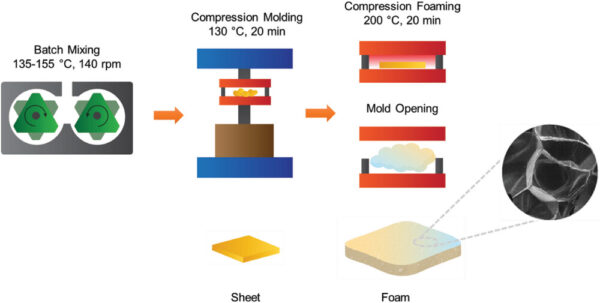

TPE, like SEBS, is prone to shrinkage when made into foam due to its low modulus. However, by crosslinking before foaming, elastomer modulus can be increased. Using this methodology, researchers sought to leverage SEBS’s properties with foams’ cost-efficiency and environmental friendliness.

You can also read: Effective Pollutant Absorption Using Polyurethane Foams.

Researchers employed compression foaming to fabricate the SEBS foam. Image courtesy of Fabrication of Triblock Elastomer Foams and Gelation Studies for Oil Spill Remediation.

Simulating Real-World Applications

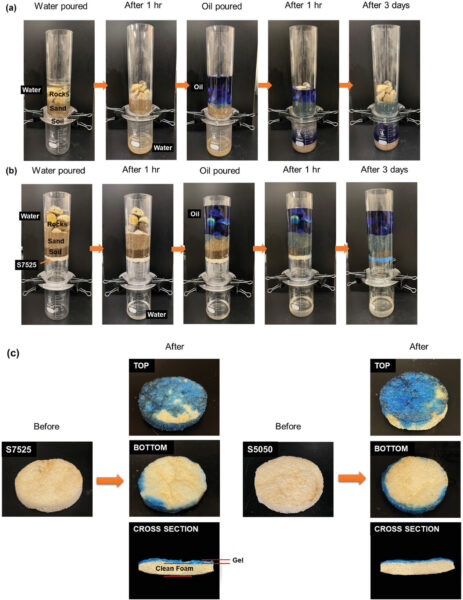

To assess the material’s effectiveness, researchers simulated a groundwater contamination environment in a 6 cm plastic tube. Within the tube, researchers layered fine-grain soil, fine-grain sand, medium-grain sand, and topped with small rocks. Researchers layered the miniature environment on top of a sample of the SEBS foam, punctured 5x to increase water flow.

By simulating the natural environment, researchers texted the foam’s applicability as a barrier for oil contamination in groundwater. Image courtesy of Fabrication of Triblock Elastomer Foams and Gelation Studies for Oil Spill Remediation.

Researchers poured 200 mL of both water and Hyvolt oil into the tubes with and without the foam layer. During the experiment, they recorded the amount of time for both the water and oil to pass through the substrate. The simulation’s results showed that, after a three-day evaluation period, no oil leaked through the foam layer. Gel formed a layer over the top of the foam samples, creating a physical barrier that prevented oil flow. Due to the porous nature of the foam, the water completely evacuated the foam layer.

This foam shows a novel application of SEBS for mitigating oil spills in groundwater. Unlike traditional polymeric foams, SEBS foam contains oil even when the amount exceeds the foam’s absorption capacity. This material offers a viable alternative for traditional absorption methods, which are not always effective against groundwater pollution.