Rapid Liquid Printing Unlocks 4D Silicone Structures

Novel printing techniques unlock kinetic design and enable the creation of innovative, responsive environments that adapt to movement and interaction.

Recently, many innovations in architecture have focused on material innovation, wherein materials generate innovative approaches to design. Responsive, four-dimensional (4D) printed materials can create even more possibilities in architecture and beyond. 4D printing of active materials typically relies on high-end multi-material printers and proprietary materials, which can limit the accessibility of research in this field. By employing Rapid Liquid Printing (RLP), researchers seek to enable the design of soft, responsive 4D structures using off-the-shelf materials.

You can also read: Principles Governing 4D Printing.

Using Gel as a Support Structure

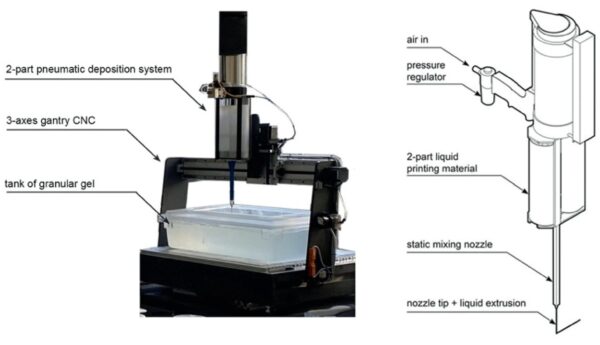

RLP uses a gel suspension to limit the support structures required by traditional additive manufacturing processes. The extruder prints liquid materials within a tank of gel. By swapping material cartridges during printing, researchers could use RLP for multi-material printing.

RLP directly extrudes printed materials into gel, which acts as the support structure. Courtesy of 4D Soft Material Systems.

Achieving Active and Passive Responses in Silicone

Responsive material systems fall into the active or passive categories. In active systems, the material’s shape-shifting occurs due to a change in the external environment, such as temperature. Passive systems change due to internal forces, such as chemical reactions. In this study, researchers investigated using RLP for both system types.

Silicone and ethanol, when combined, are examples of materials suitable for an active 4D system. When heated, ethanol expands, changing from liquid to gas. Then, it returns to its original shape after the heat source is no longer present. Using layered materials—silicone and a silicone-ethanol mixture—it is possible to print a smart, thermostrictive composite. RLP then allows for larger-scale applications of this technology.

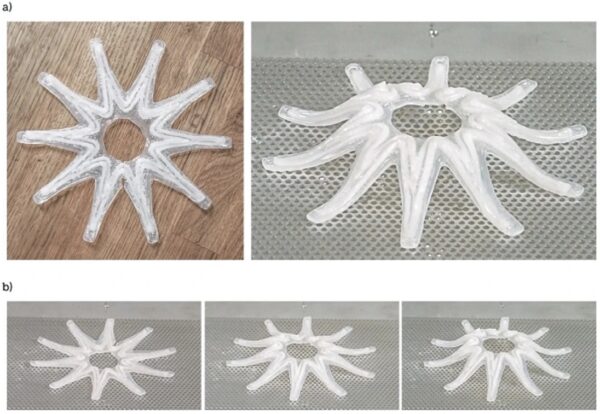

Researchers used this method to print a star-like material. With a diameter of fifteen centimeters, it took only five minutes to print. After two minutes of exposure to a temperature of 70 °C, it exhibited the shape-changing behavior shown below.

When heated, this star-like fabrication comprised of plain silicone and silicone-ethanol exhibits a change in shape. Courtesy of 4D Soft Material Systems.

Polyvinylsiloxane (PVS) bi-layers have an anisotropic swelling capacity that enables passive shape-changing systems. When using different silicones with different moduli for the layers, one layer will expand relative to the other. Changing the thickness ratio of the layers changes the magnitude of this effect. This allows for precise control over curvature in bi-layer structures. When investigating this effect, researchers found that the main direction of the active material influenced bending orientation.

Breaking Down the Barriers of 4D Printing

This study found that a silicone-ethanol mixture and PVS bi-layers are both feasible materials for RLP applications. Using RLP for 4D printing applications opens the door to scalable, complex shape-shifting structures. By leveraging RLP, researchers can take advantage of readily available materials, like silicone. This limits the need for proprietary materials and costly multi-material printers, further expanding the possibilities of 4D printing for designers.