Polymer Solution Casting: A Tool for Advanced Medical Applications

Polymer solution casting enables precise, cost-effective thin films and membranes, advancing control and performance in medical applications.

In the rapidly evolving landscape of medical technology, the demand for innovative materials and fabrication techniques drives progress. Polymer solution casting offers a versatile, cost-effective way to produce thin polymer films and membranes with precise control over their properties. This technique involves dissolving a polymer in a solvent, casting the solution onto a substrate, and then evaporating the solvent. It finds growing use across many medical applications, from advanced drug delivery systems to sophisticated tissue engineering scaffolds.

You can also read: Melt Electrowriting for Biomedical Applications

The Technical Fundamentals of Solution Casting

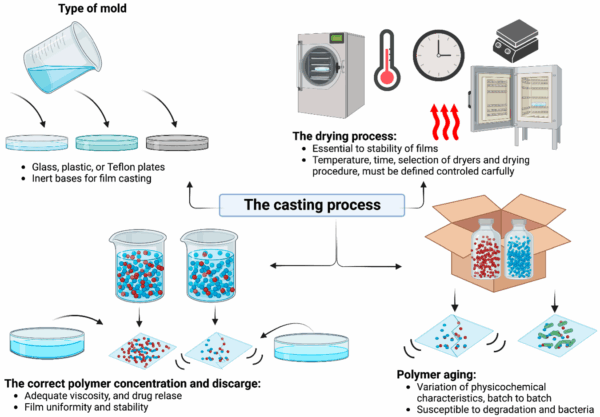

Overview of Solution Casting for Polymer Films. Courtesy of Films for Wound Healing Fabricated Using a Solvent Casting Technique.

Polymer Dope Preparation

Solution casting begins with preparing a homogeneous polymer “dope,” made by dissolving a polymer in a volatile solvent. Polymer and solvent choice depends on solubility, film properties, vapor pressure, and toxicity. The solution must be uniform, often under controlled temperature and pressure. Operators then de-aerate and filter it to remove bubbles and impurities. Polymer concentration and molecular weight set the viscosity, a key factor in casting.

Casting Techniques

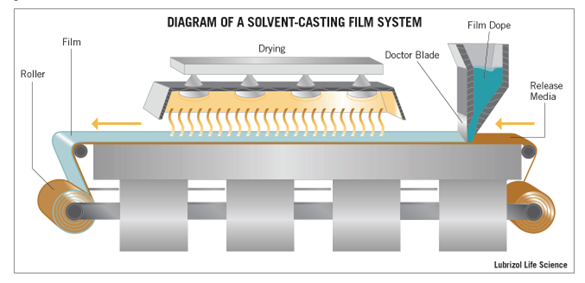

Doctor blading or knife coating technique, one of several methods for polymer solution casting. Courtesy of Agno Pharma.

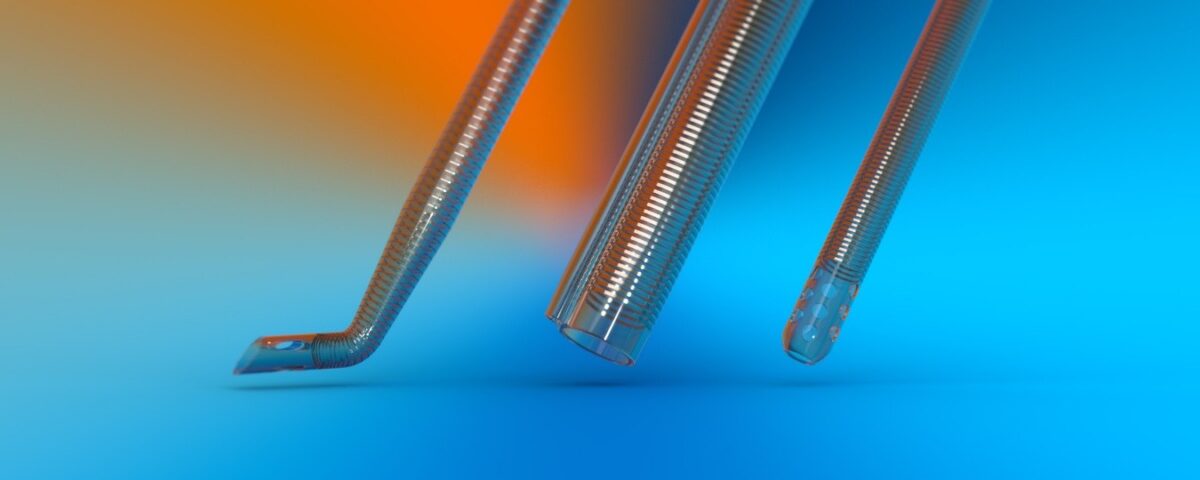

Operators spread the dope onto non-adherent substrates such as polished steel, glass, or fluoropolymers. Different methods control thickness and uniformity. Doctor blading sets the layer with blade gap and viscosity. Spin coating distributes solution on a rotating substrate, where centrifugal force creates thin films that scale with spin speed. Dip coating immerses and withdraws the substrate at a controlled rate, influenced by viscosity and surface tension. For tubular structures, mandrel casting dips an inner mold into the solution and withdraws it slowly; repeated cycles build wall thickness and enable reinforcement.

Solvent Evaporation Dynamics

The critical phase is solvent evaporation. As molecules escape, solvent concentration falls, polymer fraction rises, and viscosity increases. The rate depends on vapor pressure, temperature, humidity, and airflow. Rapid evaporation can form a dense skin that traps solvent, causing bubbles or uneven drying. It may also lead to roughness or “coffee-ring” patterns. In unstable regions, phase separation alters morphology, porosity, and mechanical properties. Slower evaporation allows chain rearrangement, producing smoother, denser films.

Post-Casting Operations

After the primary solvent evaporates, post-casting steps include further drying and annealing. Even small amounts of residual solvent can affect mechanical behavior, glass transition, and biocompatibility. To meet strict limits, engineers dry films under vacuum or at elevated temperatures, then anneal them to improve stability, release stresses, and promote chain relaxation or crystallization. Careful control of preparation, casting, and evaporation lets engineers fine-tune thickness, porosity, surface, and mechanical properties.

Key Advantages for Medical Use

Polymer solution casting appeals to medical applications because it offers precise control over film properties. Engineers can adjust thickness from a few to hundreds of micrometers and fine-tune porosity, surface roughness, and crystalline structure by managing solvent evaporation and polymer–solvent interactions.

Another strength is the ability to incorporate bioactive agents directly into the process. Researchers can mix APIs, growth factors, nanoparticles, or other therapeutic molecules into the polymer solution before casting. As the solvent dries, these agents distribute evenly through the matrix, enabling controlled and sustained release. This capability is especially valuable for drug-eluting implants or medicated wound dressings, where dosage and timing are critical.

Medical polymers such as PLGA, PCL, PVA, and cellulose derivatives are biocompatible and easy to process by solution casting. The films withstand sterilization methods like gamma irradiation or ethylene oxide. Solution casting is also cost-effective and simple at lab scale, and while industrial production needs specialized equipment, the core process stays practical for certain high-volume applications.

Diverse Medical Applications

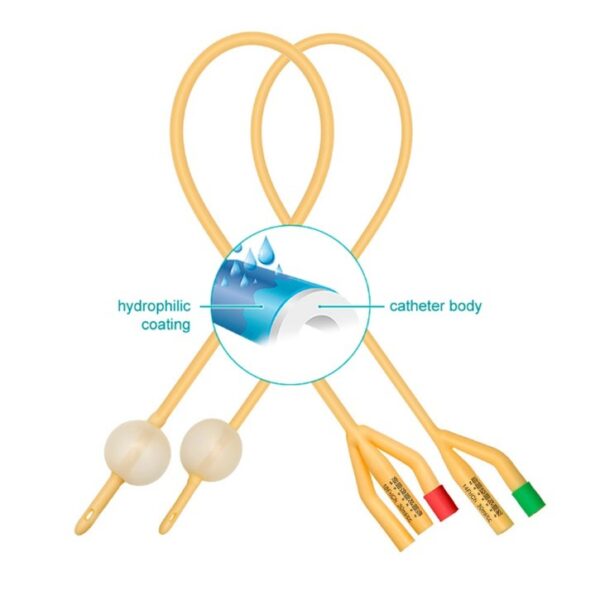

Polymer coatings on catheters serve to improve performance and prevent infections by providing properties like reduced friction, enhanced lubricity, and antimicrobial activity. Courtesy of Mederen.

Polymer solution casting’s finds wide application in medicine, especially in drug delivery. Films support transdermal patches that bypass digestion, oral dissolvable films for pediatric and geriatric care, and implantable systems for localized release in oncology or ophthalmology. Precise control over drug loading makes the technique well suited for these applications.

Beyond drug delivery, solution-cast films also serve as advanced wound dressings. Thin, flexible, and often permeable, they protect wounds, maintain moisture, and deliver agents such as antimicrobials or growth factors to accelerate healing. In tissue engineering, solution casting fabricates thin-film scaffolds that mimic the extracellular matrix, providing a surface for cells to attach, grow, and differentiate. These scaffolds guide regeneration in skin grafts, nerve conduits, and even complex 3D constructs.

Diagnostic strips also rely heavily on this technique. Point-of-care devices such as glucose meters and pregnancy tests rely on precisely cast membranes containing reagents for fast, accurate detection. Finally, solution casting adds functional coatings to medical devices. Manufacturers coat stents and catheters to improve biocompatibility, reduce friction during insertion, or deliver drugs that prevent restenosis or infection.

Challenges and Future Perspectives

Looking ahead, researchers are addressing these challenges with “green” solvents that reduce environmental impact and toxicity, along with new polymers offering better biocompatibility and controlled biodegradability. They are also adding advanced features. Stimuli-responsive polymers adapt to physiological cues such as pH or temperature, while nanomaterials enhance strength, enable targeted drug delivery, and improve imaging. Together, these innovations will expand the role of solution-cast films in next-generation medical devices and therapies.