Plastic Processing “Must have” Equipment

Plastics professionals from Baerlocher, Baylor, Dri-Air, and ENTEK reveal the critical lab equipment driving research, innovation, and quality assurance.

Plastics professionals rely on advanced tools that make research, testing, and product development possible. Whether in a university laboratory or a corporate technical center, equipment determines the precision of experiments, the speed of innovation, and the quality of results. For engineering students, mastering instruments can shape career opportunities. For companies, especially those producing additives to improve recycled plastics, must-have equipment is the foundation of competitive advantage.

You can also read: Advancing Microplastics Characterization with FT-IR Microscopy.

Industry experts from Baerlocher, Baylor University, Dri-Air Industries, and ENTEK highlight the critical devices that support material science, quality assurance, and efficient processing.

Essential Tools for Plastic Processing Highlighted by Baerlocher

At Baerlocher USA, Technical Specialist Ian Query identifies several indispensable instruments for polymer research and additive development.

Melt Flow Indexer: This is a baseline tool that measures the flow of molten resin under set conditions. Understanding how additives influence flow is essential.

Rheometer – Goes deeper than the melt flow indexer, characterizing resin behavior under varying shear rates and temperatures. This insight predicts how polymers will perform in real-world processing, such as film extrusion.

Differential Scanning Calorimeter (DSC): This analyzes thermal behavior, stabilizer loadings, crystallinity, and contamination. Its oxidative induction test assesses how resistant materials are to breakdown in oxygen-rich conditions.

Lab-scale extruders and Mixing Bowls: Simulate the harsh recycling cycles that resins experience. These allow researchers to test stabilizers, compound new blends, and experiment with novel solutions.

Together, these devices provide Baerlocher with the ability to measure, predict, and innovate around additives and recycled materials.

Building a Research Powerhouse at Baylor University

When David Jack arrived at Baylor University to lead its advanced materials program, the lab had just one functioning machine. Today, the facility spans 10,000 square feet, with expansion to 15,000 underway, and nearly $5 million invested in state-of-the-art equipment.

Among its most in-demand tools are:

MARS 40 Rheometer – Delivers high-resolution data on material performance.

JEOL Scanning Electron Microscope (SEM) – Provides detailed imaging for polymers and composites, in constant demand by students and faculty.

Programmable Ovens – Critical for both thermoplastics (drying) and thermosets (curing), often booked for eight to 24 hours at a time.

Jack emphasizes continuous upgrades, noting the lab is already on its third generation of rheometers and fourth generation of programmable furnaces. These improvements allow for more accurate modeling, broader imaging capabilities like micro-CT, and stronger collaboration with industry partners.

“The upgrades not only strengthen our research but also make our students highly marketable,” Jack says. For an industry-driven lab, keeping equipment current is both a necessity and an advantage.

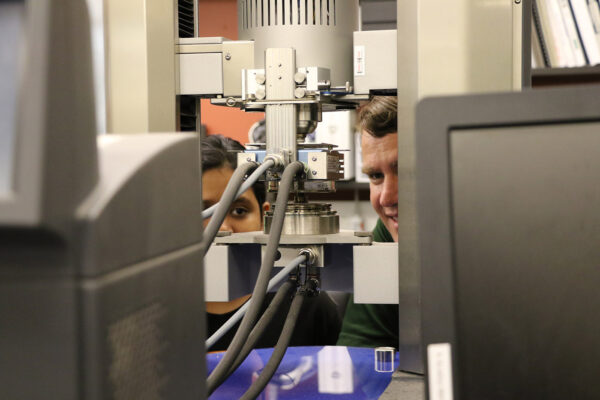

Baylor University’s David Jack (right) assesses the column of a MARS 40 rheometer with student Rifat Nargis. Courtesy of Baylor.

Dri-Air Industries: Handling High-Value Materials in Research

In many research settings, the drying process can be just as critical as the testing itself—especially when advanced polymers cost thousands of dollars per ounce. At the University of Massachusetts Lowell, for example, Dri-Air dryers support studies that involve multiple resins at once, ensuring each material is prepared under controlled conditions.

Labs frequently rely on:

Micro and Portable Dryers – suited for very small sample sizes, sometimes as little as 10 grams.

Multi-Hopper Banks – useful for preparing several resins simultaneously at different temperatures.

Compressed Air Systems – capable of wide temperature ranges without requiring cooling water.

Digital controllers and customized hopper banks allow researchers to manage conditions remotely, an advantage in clean-room settings where minimizing movement is essential. As Jason Sears, president of Dri-Air, observes, the pressure to process as many samples as possible in limited time makes efficiency a constant priority in academic and industrial labs alike.

As Jason Sears, president of Dri-Air, explains, “Labs run as many samples as possible in limited time—our systems help them maximize every trial.”

Micro dryers from Dri-Air Industries run with shop gas or nitrogen and are ideal for labs that need to run as little as 10 grams of material. Courtesy of Dri-Air.

ENTEK: Flexible Extrusion for Rapid Trials

At ENTEK’s Pilot Plant in Oregon, extrusion systems are designed for frequent changeovers. The lab often reconfigures from one trial to another in just a few days, moving between applications as diverse as composite decking and specialty pellets. Key features include quick-change tools, mobile downstream equipment, and versatile feeders that streamline set-up. Supporting devices—ranging from pelletizers and pycnometers to simple aids like cement mixers or even slow-motion video—give operators practical ways to troubleshoot and optimize runs.

Dean Elliott, ENTEK’s technical processing manager, notes that lean principles drive this approach: where once teams were needed to perform changeovers, one operator can now manage the process efficiently. For a research environment where time and accuracy are paramount, that flexibility helps shorten testing cycles and accelerate results.

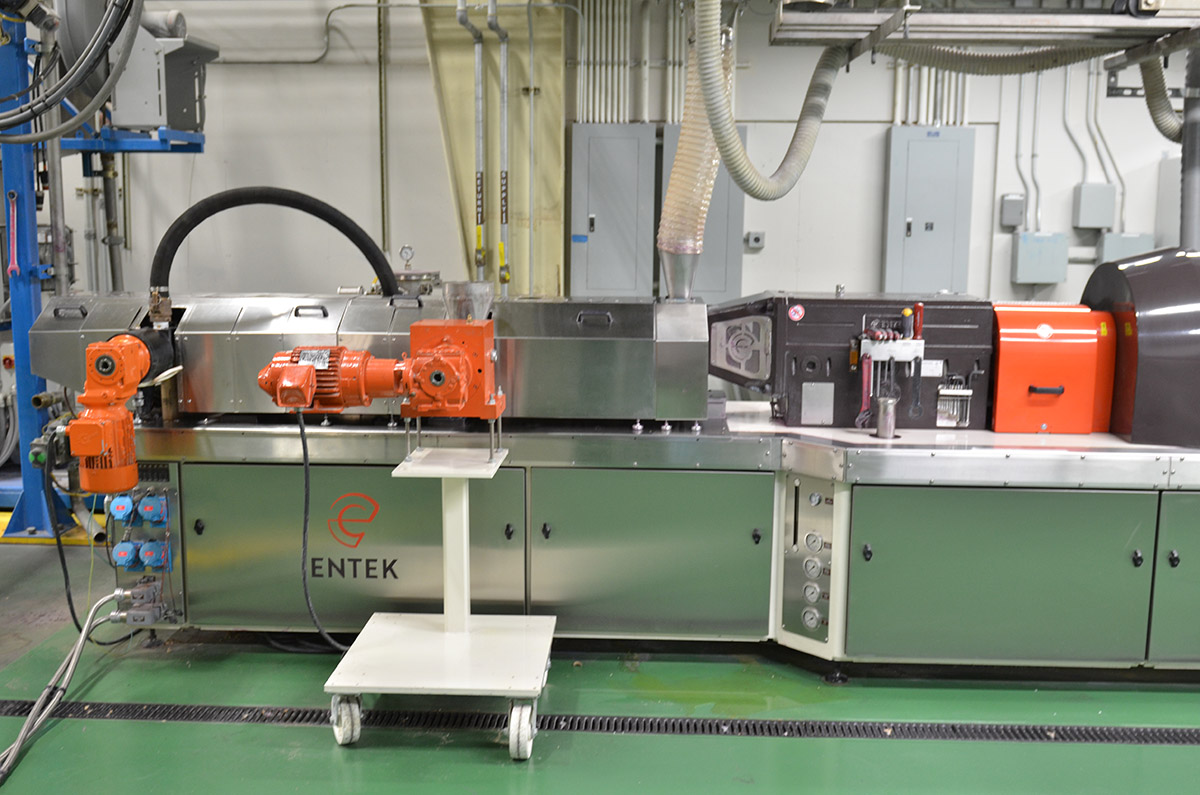

ENTEK point-of-use tool sets allow quick adjustments of extrusion systems in use for processing tests at the company’s Pilot Plant. Courtesy of ENTEK.

Conclusion: Equipment as the Backbone of Innovation

Across university labs, additive producers, and pilot plants, equipment continues to shape the pace and quality of plastics research. The tools in use—whether for drying, compounding, or analyzing materials—provide the foundation for discoveries and innovations. As research demands grow more complex and materials more valuable, maintaining efficient, reliable equipment will remain central to advancing both academic training and industrial problem-solving.

A 43mm extruder in ENTEK’s pilot plant. Courtesy of ENTEK