Evaluating the Impact of Glass Fillers on Polymer Powder Aging for AM

Researchers have evaluated the effects of glass fillers on the aging behavior of polymer powders for additive manufacturing (AM).

Powdered–polymer additive manufacturing (AM) is a 3D printing technique that involves preheating and selectively melting consecutive layers of powder. It is widely used in several industries because it offers design flexibility, enables self-supporting structures, and provides material versatility. Moreover, the unfused powder remaining after the process can be reused, representing both a sustainable and economically efficient advantage.

However, although the unfused powder does not undergo fusion, exposure to elevated temperatures alters its structure, properties, and behavior. As a result, numerous researchers have studied the effects of thermal aging from AM on different polymer powders. Nevertheless, most of these studies have focused primarily on pure polymer powders. To bridge this gap, recent research has examined how glass-filled polymer powders age and how these fillers influence the properties of the resulting printed parts.

You can also read: Recycled PETG Powers Carbon Fiber Filaments for 3D Printing.

Methods: Powders, Tests, and Aging Setup

The study compared glass-filled nylon-12 (PA615-GS) and unfilled nylon-12 (PA650). Researchers simulated thermal aging using a Vacucell oven under a nitrogen atmosphere. They characterized virgin and aged powders with:

Size exclusion chromatography (SEC) for molecular weight changes.

Differential scanning calorimetry (DSC) for crystallization and melting behavior.

Rotational rheometry for viscoelastic properties.

They also produced test specimens via high-speed sintering (HSS) and assessed their mechanical behavior according to ASTM D638 tensile standards.

Molecular Weight Increases During Aging

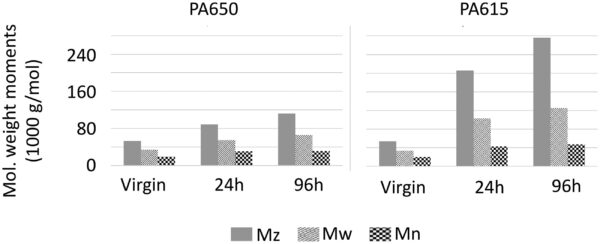

SEC results demonstrated that aging increased molecular weight in both filled and unfilled nylon-12. The most pronounced effect occurred in Mz (z-average molecular weight), suggesting the formation of very high-molecular-weight chains. This increase likely resulted from polycondensation during aging. Notably, the observed modifications align closely with findings from previous studies on pure nylon-12.

Comparison of molecular weight moments—Z-average (Mz), weight-average (Mw), and number-average (Mn)—for PA650 (left) and PA615 (right) powders. Courtesy of Investigating the effect of glass filler on the aging behavior of polymer powders for additive manufacturing.

Crystallinity Declines with Thermal Aging

DSC revealed decreases in peak melting temperature, crystallization temperature, and melt enthalpy for both filled and unfilled powders. These changes result from higher molecular weight, which produces less dense spherulites and consequently lowers crystallinity.

Linear relationship between Mz molecular weight and thermal properties, including melt enthalpy and peak crystallization temperature. Courtesy of Investigating the effect of glass filler on the aging behavior of polymer powders for additive manufacturing.

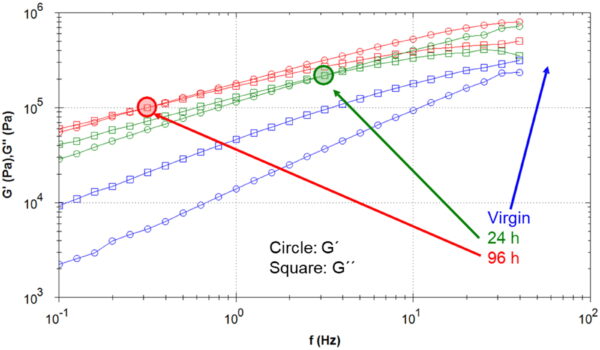

Elasticity Increases in Aged Powders

Rheological testing confirmed aged samples were more elastic, with increased shear modulus and longer relaxation times. These results are directly linked to crystallization changes observed earlier.

Influence of aging duration on the storage modulus (G’) and loss modulus (G”) of PA615 glass-filled powder samples. Courtesy of Investigating the effect of glass filler on the aging behavior of polymer powders for additive manufacturing.

Mechanical Properties Shift in Printed Parts

Mechanical testing of printed specimens showed stiffer materials with modified ductility after powder aging. These findings indicate that powder aging propagates into the final part properties.

Influence of powder aging on the tensile properties of PA650 and PA615-GS. Courtesy of Investigating the effect of glass filler on the aging behavior of polymer powders for additive manufacturing.

Expanding Knowledge and Guiding Future Research

Overall, thermal aging affects both virgin and filled powders. Characterization tests showed changes in molecular weight, crystallization, melting point, viscoelasticity, and mechanical performance. In fact, some changes, such as elasticity and crystallization shifts, appeared more pronounced in glass-filled powders than in unfilled ones.

This study expands knowledge of polymer powders exposed to heat during AM, which is critical for predicting the performance of printed parts. Moreover, it encourages research on new fillers that may reduce aging effects in polymer powders.