Designing High-Value Plastic Products with a Soft Feel

Widely used in consumer goods, these specialty coatings give plastic surfaces a sleek, smooth, suede-like texture that enhances both look and touch.

Soft-feel coatings offer a warm, velvety, matte texture to plastic products as an alternative to complex, shiny textures. Initially developed by German company Bayer in the 1990s, these coatings retain popularity in consumer products today. Soft-feel coatings are primarily comprised of polyurethane (PU), silicon rubber (SR), or polyacrylic acid (PAA). These materials can add value to specific products, such as phone cases, where the tactile feel may influence consumer decisions. These coatings can also increase a product’s scratch, weather, and solvent resistance.

You can also read: Revolutionizing Textiles: Innovative Coatings for a Cool-Touch Effect

The Pitaka™ 1500 D Kevlar fiber polymer composite phone case, which combines soft feel, impact resistance, and light weight. Courtesy of Soft Feel Material Coatings on the Surface of Plastic Products and Their Application Prospects in the Popular Fields: A Review.

Human Tactile Perception of the Soft Feel Effect

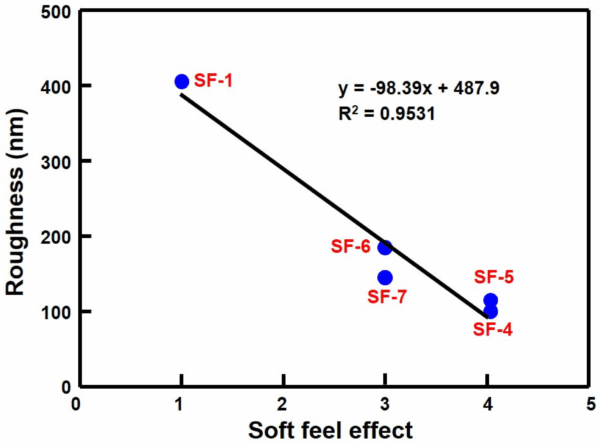

The soft feel of a material as a quantifier of value is subjective. Thus, when designing products with a soft feel, it is important to consider consumer preference in relation to material properties. In 2023, researchers conducted a study allowing participants to rank the soft feel effect of various materials. The study found that coatings with the highest flexibility had the best-ranked tactile effect. The best soft feel corresponded with higher hardness, medium modulus, lower roughness, and lower friction coefficient.

Coatings ranked with the best soft feel effect had a lower coefficient of friction and lower surface roughness. Courtesy of Soft Feel Material Coatings on the Surface of Plastic Products and Their Application Prospects in the Popular Fields: A Review.

Other studies concluded that tactile sensation depended on more factors than just material surface characteristics. Vision can also influence perception of material softness, since it provides similar information to factors like roughness and particle size.

Advancements in Soft Feel Plastics

In a 2013 study by Zhang et al., researchers developed an elastic tactile coating for acrylonitrile butadiene styrene (ABS) resin. ABS resin is prone to defects such as uneven colors and blemishes, as well as issues such as brittleness. A soft feel coating can significantly improve ABS’s disadvantages, while improving the beauty of products made from it. Zhang et al.’s coating comprised linear hydroxyl polyester, TS100 matting powder, catalyst solvent, leveling agent, curing agent, etc. This study found that silicone leveling agents provided smoothness, while acrylic leveling agents provided a leather-like feel.

In 2013, a company in Shanghai, China developed an alternative to direct spraying of soft-feel coatings. Instead, they laminated soft feel films on the surfaces of paper, plastic, and other materials. The following year, a Dutch company developed the DuraSilk UV coating, which is UV-curable at low temperatures.

Future avenues for research may expand upon recent developments or investigate multiple-material composites to expand material applications. Additionally, optimizing sustainability and affordability, while increasing qualities such as anti-fingerprint and anti-static properties, are of upmost importance. Further improving these materials can provide high-value options for various products, especially where feel is of upmost importance to consumers.