What the EV Boom Means for Plastics

Electric vehicle sales reached 17.6 million units in 2024, marking rapid growth and transforming the global automotive landscape.

Electric vehicles (EVs) have moved beyond prototypes to become a fast-growing segment of the global automotive industry. Over 17 million units sold in 2024 and forecasts nearing 22 million in 2025 show a clear growth trend. Yet, this shift relies on more than merely battery chemistry and power electronics advances. High-performance polymeric materials are essential. Plastics contribute significantly to lightweighting, thermal management, electrical insulation, and structural integration throughout EV designs.

As EV manufacturers redesign vehicle architecture to enhance energy efficiency, safety, and connectivity, plastics and polymer composites have become indispensable. These materials underpin key components, including battery modules, aerodynamic panels, thermal management systems, and charging infrastructure, enabling the performance, scalability, and sustainability that modern EVs demand.

You can also read: Silent Polyurethane Tires for Electric Vehicles.

The Numbers Keep Climbing

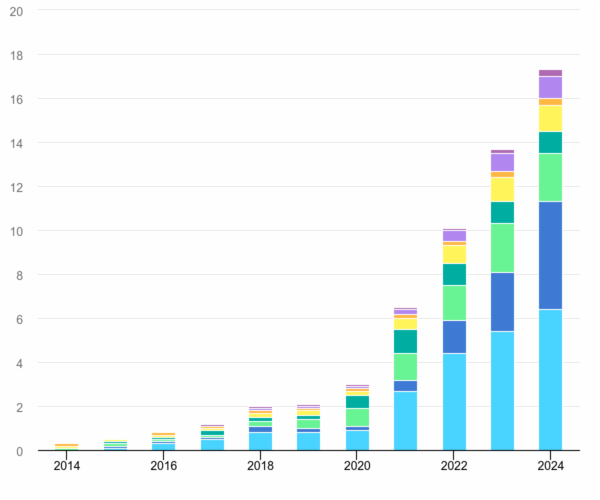

According to the International Energy Agency, global EV sales grew by 25% in 2024, hitting a record 17.6 million units. The market share of EVs reached 20% of all new vehicle sales, up from just 4.6% in 2020. Automakers sold over 5.6 million EVs worldwide in the first four months of 2025, a 29% increase from the same period in 2024.

China remains the global leader, selling 11 million EVs in 2024, representing 60% of the worldwide market. Europe sustained steady growth, driven by consistent policies and expanded charging infrastructure. In contrast, the U.S. experienced modest gains, limited by uneven infrastructure rollout and uncertainty in federal and state EV regulations.

Automakers are responding with record investments in battery production. Companies plan to bring more than 60 new gigafactories online by 2030, each designed for a capacity of 256 GWh. By then, global EV demand will require over 3,900 GWh in battery capacity, enough to power nearly 3 billion smartphones daily.

Global electric car sales 2014-2024 (Millions). Courtesy of International Energy Agency.

Plastics at the Heart of EV Design

While much of the EV conversation focuses on batteries and powertrains, the materials used in the rest of the vehicle are just as critical.

Lightweighting for Range Efficiency

Vehicle weight is one of the biggest factors affecting EV range. Every 10% reduction in weight can boost energy efficiency by up to 8%. Plastics and composite materials offer a high strength-to-weight ratio that metals struggle to match.

Manufacturers now commonly use PP, PA, and glass fiber-reinforced polymers to produce underbody shields, dashboards, front-end modules, and exterior panels. These materials reduce overall vehicle weight while enhancing impact resistance and corrosion protection.

Battery Systems and Safety

The core of every EV, the battery pack, relies heavily on plastics. Manufacturers fabricate cell holders, module frames, thermal barriers, and insulation layers using materials such as PC, PET, and PBT. These polymers provide dimensional stability, electrical insulation, flame retardancy, and resistance to chemicals and high temperatures.

Thermal and Electrical Management

Power electronics and e-motors generate significant heat. Engineers develop high-performance plastics with tailored thermal conductivity to dissipate heat efficiently. Materials such as thermally conductive PBTs, PA6/PA66 blends, and liquid crystal polymers manage thermal loads while complying with safety regulations like UL 94 V-0 flammability standards.

In addition, electromagnetic interference shielding is becoming more critical as EVs integrate more sensors and digital systems. Conductive polymers and hybrid materials are emerging to meet these needs.

Charging Infrastructure and Connectors

The rapid growth of charging stations, public and private, creates demand for durable, weather-resistant, and flame-retardant plastics. Charging gun handles, cable insulation, terminal enclosures, and wall-mounted boxes all rely on engineered polymers like thermoplastic elastomers (TPEs), PC/ABS blends, and fiber-reinforced resins.

Interior Innovation and Smart Surfaces

EV interiors are undergoing a transformation. Features like large touchscreens, ambient lighting, voice-controlled interfaces, and minimalist dashboards demand materials that are lightweight, easily shaped, and tactile-friendly. Plastics, from soft-touch door trims to 3D-printed vent components, enable design flexibility while maintaining durability and visual appeal.

Circularity, Regulation, and Next Steps

Regulations like the EU’s End-of-Life Vehicles Directive and the upcoming Battery Regulation demand transparency, recyclability, and reduced environmental impact. This drives innovation in circular plastics. Some OEMs now mandate using recycled materials for up to 25% of plastic components in EVs. Meanwhile, suppliers explore chemical recycling, mass balance accounting, and bio-attributed resins to reduce carbon footprints while maintaining performance.

As the electric vehicle market grows rapidly, plastics will play a key role in shaping the future of transportation. The industry still faces challenges in improving sustainability by using better recycling methods and greener materials. Finding the right balance between performance and recyclability will be essential to making sure plastics help drive innovation and support a cleaner, more sustainable future.