Single-Screw Pump Redesign Using Moldflow

Using Moldflow analysis, researchers seek to optimize a rubber component in single-screw pumps, increasing the efficiency of oil production equipment.

Double-Helix Design

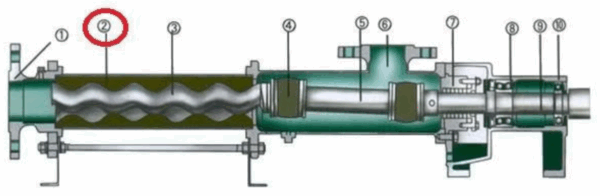

Single-screw pumps can effectively handle viscous fluids and solids, making them pivotal to the oil industry. Their performance and reliability play a direct role in the efficiency of the oilfield. Within these pumps, a rubber component, the stator, plays a central role in their functionality. The stator transports liquid through the pump, increasing pressure through its spiraled inner cavity. As the pump’s screw rotates, it draws in liquid, pushing it along the stator’s grooves, then discharging it. This requires the stator to have a complex, double helix structure. Current injection molding processes provide insufficient quality for the stators, but advanced techniques can help to address this. By enhancing the efficiency of the stator and pump, manufacturers can help bolster oilfield operations.

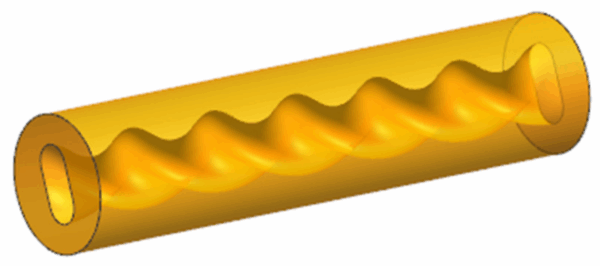

The rubber stator (2) has a double helix shape, making injection molding difficult. Courtesy of Design and Optimization of the Injection Mold for Rubber Stators in Oil Production Single-Screw Pumps.

You can also read: The Importance of Mold Temperature Control in Injection Molding.

Optimizing the Stator’s Injection Molding Process

Seeking to improve the stator’s design, researchers established a finite element model of the part. Then, they meshed the model, manually adding flow channel nodes, and conducted a connectivity diagnosis. Nitrile rubber (NBR) was the chosen material for the part. NBR is resistant to oil and chemicals, is tough and resistant to wear, and has a wide operating temperature range. These properties make it suitable for the stator of single-screw pumps.

When making the stator, manufacturers must clamp a core-pulling mechanism within the cavity and extract it during demolding. Courtesy of Design and Optimization of the Injection Mold for Rubber Stators in Oil Production Single-Screw Pumps.

This study involved testing various injection molding parameters. Using MOLDFLOW software, researchers explored effects of the mold temperature, melt temperature, injection time, holding pressure, and holding time. Results showed that mold temperature had the greatest effect on part quality, with a significant effect on volume shrinkage.

Optimizing the mold and melt temperatures reduced the volume shrinkage and sink index, in turn, improving quality. The following injection molding parameters produced the best results:

- Mold temperature: 100 °C

- Melt temperature: 70 °C

- Injection time: 30 seconds

- Holding time: 10 seconds

- Holding pressure: 60 MPa

In the oil industry, the reliability and quality of stators is paramount for oil production. By improving the quality and consistency of these parts, their operational efficiency can increase. Making considerations for individual components, such as the stator, can lead to better overall equipment reliability and performance. By better understanding how injection molding principles apply to specific components, manufacturers can increase part functionality.