Nano Molding: The Future of Metal-Plastic Integration in Electronics

As electronics demand slimmer, stronger, and more sustainable designs, Nano Molding Technology (NMT) is emerging as a key innovation.

Nano Molding Technology (NMT) has gained momentum as a key innovation. By combining advanced injection molding precision with the structural advantages of metal–plastic hybrids, NMT unlocks new design flexibility and performance levels. Driving this advancement, SABIC has launched LNP™ THERMOTUF™ WF0087N—the first flame-retardant PBT-based compound engineered specifically for NMT in consumer electronics.

You can also read: SABIC Makes Polycarbonate From Mixed Recycled Plastics.

SABIC’s Game-Changing Material for NMT

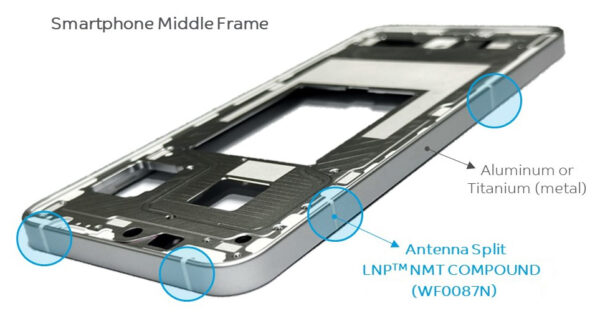

SABIC’s new LNP™ THERMOTUF WF0087N compound sets a new standard for NMT-compatible materials. This 2025 Edison Award-winning polymer blends polybutylene terephthalate (PBT) with excellent flame retardancy (UL94 V0 at 1.0mm) and high mechanical strength, making it ideal for electronic device components such as antenna splitters, middle frames, and housings in smartphones, tablets, and wearables. Its 60% stronger bond to metal surfaces sets this material apart from traditional flame-retardant PBTs. This performance leap helps device manufacturers meet strict IP68 water and dust resistance standards while ensuring long-term mechanical integrity. In addition to structural strength, the material offers robust chemical resistance—even against harsh anodizing treatments—and custom colorability for brand-specific finishes. Importantly, its dielectric properties help maintain optimal signal transmission in antenna-rich devices.

How Nano Molding Technology Works

Nano Molding Technology is a hybrid process that chemically and mechanically bonds thermoplastics to treated metal surfaces. Unlike insert molding or adhesive bonding, NMT achieves micro- and nano-scale adhesion by allowing plastic to flow into pre-treated nano-cavities on the metal surface during injection.

This results in a tight, durable bond that eliminates the need for glues or mechanical fasteners, simplifies manufacturing, and enhances product aesthetics.

Advantages of NMT: Where Engineering Meets Design

1. Superior Bond Strength

NMT creates mechanically interlocked interfaces between plastic and metal, delivering bonding strength significantly higher than insert molding. SABIC’s compound further strengthens this connection, making the joint more resilient under mechanical and thermal stress.

2. Lightweight and Thin-Walled Designs

By allowing plastic components to replace heavier metal parts without sacrificing structural performance, NMT supports the trend toward slimmer, lighter devices. The process enables thin-wall applications critical for next-gen consumer electronics.

3. Radio Frequency Transparency

One of the standout benefits of NMT is that the plastic layer remains transparent to RF signals, enabling high-performance antenna placement while maintaining structural support from metal components. This makes it perfect for multi-antenna smartphones and smartwatches.

4. Enhanced Durability and Environmental Resistance

SABIC’s material supports IP68-rated designs, and the NMT process helps protect internal electronics from moisture and dust, increasing the product’s lifespan. This is crucial in rugged consumer and industrial devices.

5. Streamlined Manufacturing

With NMT, manufacturers eliminate secondary operations like adhesive application or overmolding, reducing production time and cost. The result is a cleaner, faster, and more scalable workflow compared to CNC machining or die casting.

6. Precision and Material Versatility

NMT works with a range of metals—aluminum, stainless steel, magnesium—and compatible polymers like PBT, PC, PPS, and PA. It also enables fine detail replication, suitable for electronics, medical devices, and automotive interiors.

Real-World Potential and Future Applications

SABIC’s breakthrough with LNP™ THERMOTUF WF0087N proves that NMT is no longer just an innovation for R&D—it’s a manufacturing solution ready for high-volume production. As smartphones, wearables, and IoT devices grow more complex, NMT will become a go-to process for integrating performance and style.

SABIC is introducing a new, flame-retardant LNP™ THERMOTUF™ compound used in nano molded components of consumer electronics. Courtesy of SABIC.

By solving the challenges of strength, aesthetics, RF performance, and miniaturization in a single step, Nano Molding Technology offers a smarter path forward for the plastics and electronics industries alike.