Get Gate Placement Right: Tips for Straighter Molded Parts

Gate placement isn’t just a technical detail—it shapes everything from aesthetics to internal stress, shrinkage control, flow quality, and mold wear.

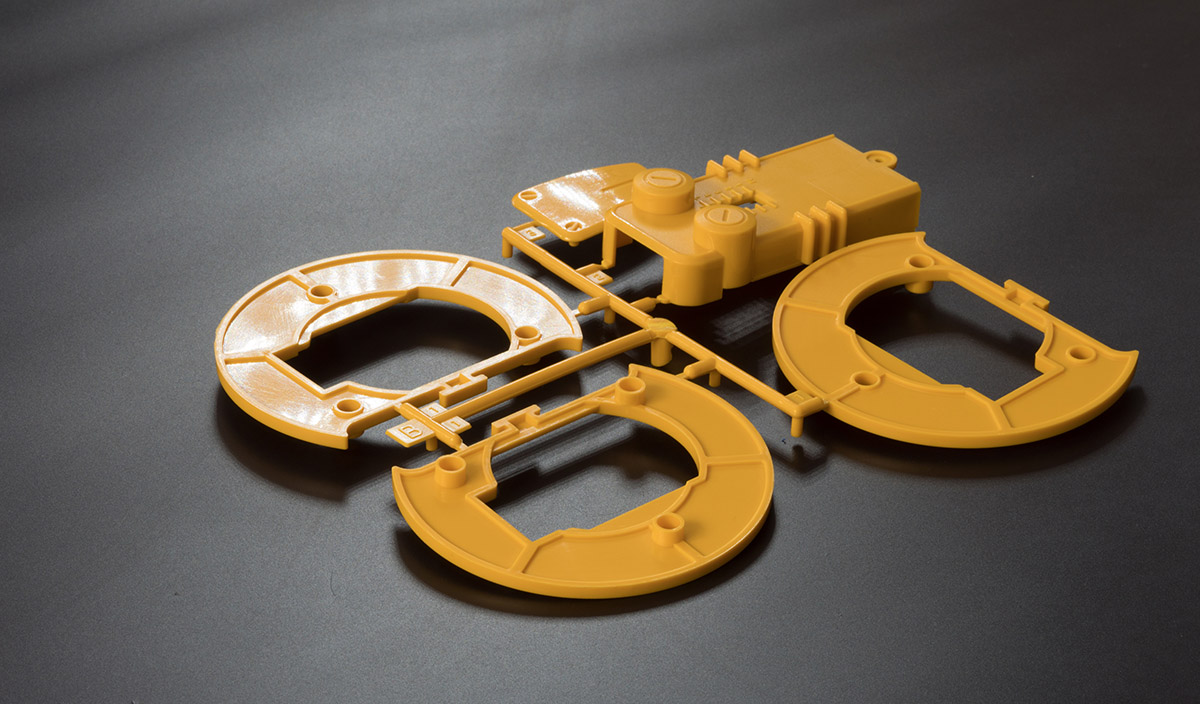

The gate is a critical point in every injection-molded component. Not only is it the entrance for all the material that will fill the cavity, but it is also a sensitive point after molding, where failure may occur. It also determines conditions such as orientation, flow marks, possible in-molded stresses, weld line placement, and air traps. Therefore, it is crucial to understand how to select the proper location.

You can also read: Design-Related Surface Defects in Injection Molding.

The Same Flow History

Aim for symmetrical part filling when placing a gate, ensuring balanced flow and consistent material behavior. Ideally, the material should flow evenly in all directions from the gate, encountering equal resistance and thermal history during filling. However, due to geometric limitations, achieving perfect symmetry is often unfeasible, though it remains a valuable target during early design. Many simulation tools offer optimized gating suggestions based on flow length and pressure drop calculations to support this effort. These simulations help identify gate locations that minimize imbalances and ensure more uniform filling across complex part geometries. If one side of the component fills more slowly, the flow front arrives cooler, increasing solidification on that side of the mold. As a result, the viscoelastic material behaves more elastically, and residual stresses are less likely to relax during cooling.

This imbalance often leads to part warpage, especially when the temperature gradient is significant across the mold surface. Additionally, temperature differences during final filling can impact the crystallization rate across the part in semi-crystalline materials. Lower thermal energy reduces crystallization, causing localized variation in shrinkage and mechanical performance in the finished component.

Fiber-reinforced Materials

Gate placement strongly influences fiber orientation and dimensional stability across the part when using fiber-reinforced materials. Material shrinkage tends to increase in directions perpendicular to the fiber alignment created during the flow process. Therefore, align fibers along the axis that requires greater mechanical strength to improve load resistance in that direction. At the same time, anticipate flow-induced orientation patterns based on gate position and account for visual or surface finish constraints. Balancing mechanical performance and appearance requires planning both the flow path and fiber layout from the earliest design phase. In summary, gate placement must consider thermal behavior, flow length, crystallinity, and fiber alignment to avoid warpage and property variation. By leveraging simulation software and applying material knowledge, designers can improve performance, appearance, and process reliability simultaneously.

Shrinkage Compensation

A basic placement rule is to fill from thick to thin. This means placing the gate over the thicker part of a component, and from there filling the thinner walls. This is important because during filling two stages take place: the volumetric filling and subsequently the gravimetric filling, or holding phase, where volume compensation occurs.

While a lack in volumetric filling is obvious during molding, a lack of volume compensation may only be evident after a quality control check of the part.

The holding phase is responsible for the part’s dimensional quality and a sufficient holding will ensure that the shrinkage is reduced. Therefore, it is important to ensure that there will be no “melt pools” in the part that will solidify isolated. Always take into consideration the path connecting the injection gate to those pools and keep the material flow open long enough to ensure solidification under pressure.

Also, ensure the gate has enough cross-section to stay open during the holding phase. Many designers focus too much on aesthetics and make the gate too small, forgetting it must remain open long enough to complete second-phase filling. Design the gate cross-section in proportion to the part’s thickness to allow proper material flow and compensate for shrinkage effectively.

Flow Defects

When defining the best gate placement, it is also important to consider that the flow front entering the mold should hit a mold wall and from there a concentric filling should start. If the flow front has no restriction, it will enter the cavity in the same way observed when purging the plasticizing unit – with a pressured stream. Think of it as a toothpaste filling a glass: this will be your flow pattern, and therefore surface defects will arise. This is called jetting.

Also, have into consideration aesthetics of the part when considering your gate placement. The gate will be a position of high shear, remaining hot over the complete filling phase. Consequently, it may show as a hot spot – in some parts this will appear as a “cloudy” or “smoked” area.

Finally, bear in mind that one of the most obvious consequences of the selection of the place where part filling starts is that it will also end somewhere, affecting weld lines and air traps. Make sure that the weld lines location is not placed in any location where the part is subjected to critical mechanical loads nor where it may affect the part aesthetics. Especially in fiber reinforced materials.

A large thermal shear may induce changes in the part surface near the gate. Courtesy of Lüdenscheid Kunststoff Institute.

Think about Core Deflection

I should probably not leave this to the end of the article, as many people will not reach this place; but this is one of the most costly and underseen mistakes you may make. Placing the gate directly over a core in your mold will cause it to deflect, affecting the molded part thickness (one side will be thicker than the other).Avoid injecting directly over a cantilevered core, as the pressure building over one side is several hundred times the atmospheric pressure and will immediately cause your core to shift.