From Polymers to Patients: Plastics in Wearable Tech

A new generation of conductive plastics allows engineers to print sensors directly onto flexible, skin-like materials, paving the way for a new era of personalized health.

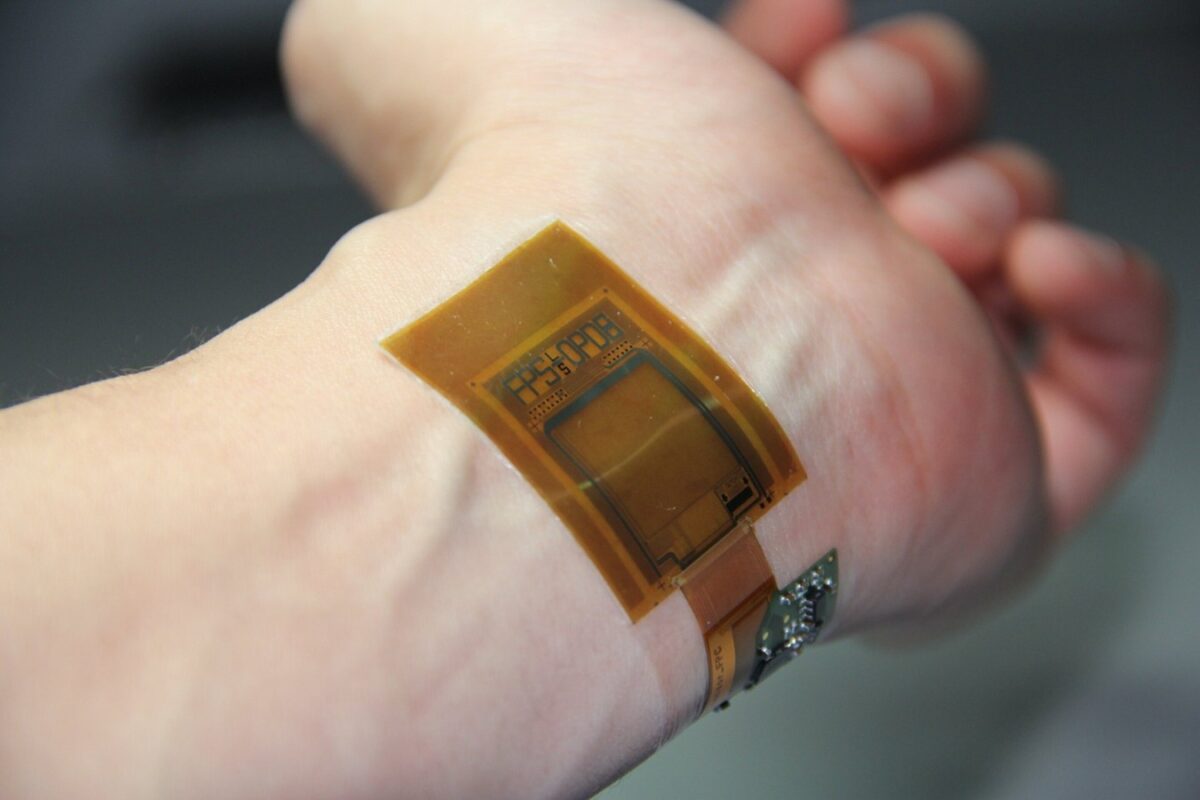

Flexible sensing platforms are becoming a breakthrough technology for non-invasive health and exercise monitoring. Polymer materials form the foundation of these sensors. Unlike traditional rigid electronics, polymer-based sensors naturally bend and conform to the human body. They also offer biocompatibility and low-cost manufacturing, making them ideal for skin-mounted and disposable devices. The rapid growth of this sector, expected to reach $9.3 billion by 2025 in healthcare flexible electronics, highlights the value of these material innovations.

You can also read: Polymeric Biosensors: A New Era in Medical Diagnostics.

The Unbeatable Advantage of Polymers

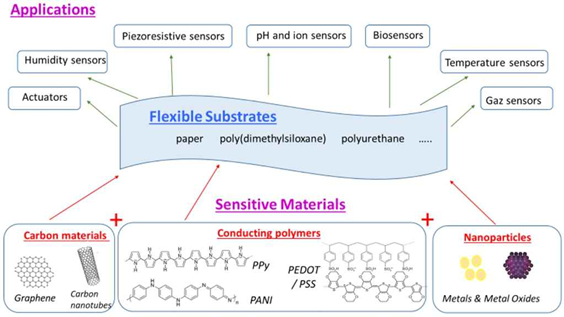

These flexible sensors work thanks to two main types of polymer materials: elastomeric substrates and conductive polymers. Elastomeric substrates, like polydimethylsiloxane (PDMS) and thermoplastic polyurethane (TPU), form a soft, flexible base that moves with the human body. Engineers choose them for their biocompatibility, low cost, and lightweight, which make them ideal for disposable or skin-mounted devices.

Conductive polymers usually serve as the active sensing element, offering electrical conductivity and mechanical flexibility. Materials like polypyrrole, polyaniline, and PEDOT: PSS behave like metals and retain the pliability typical of plastics. This unique combination enables them to act as transducers, as they respond predictably to mechanical stress or chemical exposure. The sensing principle adjusts the polymer’s conductivity, which changes precisely when it encounters external stimuli. Developers frequently blend these polymers with advanced materials, such as graphene or metal nanoparticles, to increase sensitivity and electrical performance. These hybrid composites allow researchers to fine-tune detection thresholds and broaden the range of measurable environmental or physical changes.

Key Materials for Polymer-Based Wearables. Courtesy of Flexible Sensors Based on Conductive Polymers.

A Polymer Lineup

Researchers are leveraging different conductive polymers for specific applications, often in composites that enhance their performance:

- Polypyrrole (PPy)

Known for its excellent biocompatibility and stability, PPy is a top choice for devices that come in direct contact with the body. Researchers have developed highly sensitive strain sensors by coating fabrics with an ultra-thin layer of PPy, capable of mapping body motion during exercise. When blended into composites with materials like bacterial cellulose nanofibers, PPy creates remarkably stretchable sensors that can elongate over 350% while detecting a broad range of motion with high sensitivity.

- Polyaniline (PANI)

PANI offers high conductivity, and researchers often blend it with elastic polymers to create skin-like sensors. For instance, an interpenetrating network of PU and PANI results in a hydrogel that is not only highly stretchable and sensitive enough to monitor physical activities but is also self-healing and recyclable.

- PEDOT:PSS

This polymer is a leader in the field due to its high conductivity, transparency, and stability, making it ideal for printed electronics and e-textiles. By adding it to inks, engineers can use standard inkjet printers to create stretchable, transparent electrodes for advanced sensor patches. One such patch, printed on a PDMS substrate, can simultaneously monitor both ECG and PPG signals to track heart rate and blood oxygenation.

From Inkjets to 3D Printers

This innovation lies not just in the materials but also in how manufacturers produce them. Advanced manufacturing techniques are making the scalable production of these sensors a reality.

Inkjet and screen printing allow for the rapid, precise deposition of conductive polymer inks onto flexible substrates like plastic films and even textiles. This additive approach is perfect for creating custom-patterned sensor arrays for everything from sweat analysis to environmental gas detection. For example, researchers created a flexible ammonia gas sensor by inkjet-printing a graphene-doped PEDOT:PSS composite film, which showed a threefold increase in response compared to an undoped sensor.

3D printing takes this a step further, enabling the creation of complex, three-dimensional sensor structures from polymer composite inks. This technique allows designers to perfectly tailor sensors to biological shapes, opening the door for hyper-personalized wearable devices that can track finger and arm movements with incredible precision.

Shaping the Future of Wearable Sensors

While the progress is exciting, challenges remain. Researchers are actively working to improve the long-term stability, sensitivity, and selectivity of polymer sensors. At the same time, ensuring that fully integrated systems, with onboard power, data processing, and wireless communication, remain robust, comfortable, and washable is a critical hurdle.

Even with these obstacles, polymer-based flexible sensors stand ready to transform everything from point-of-care health monitoring and fitness training to chronic disease management.

Read the full article here: Flexible sensing platform based on polymer materials for health and exercise monitoring