Foam Injection Molding: The Lightweight Revolution

Foam injection molding (FIM) delivers lighter, stronger, and more cost-effective products compared to traditional injection molding.

By creating components with solid outer skin and foamed cellular core, from automotive to electronics, FIM is solving critical challenges in weight reduction, material efficiency, and part performance.

You can also read: Sandwich Injection Molding to Increase Post-Consumer Recycled Content

How Foam Injection Molding Works

The Science Behind the Process

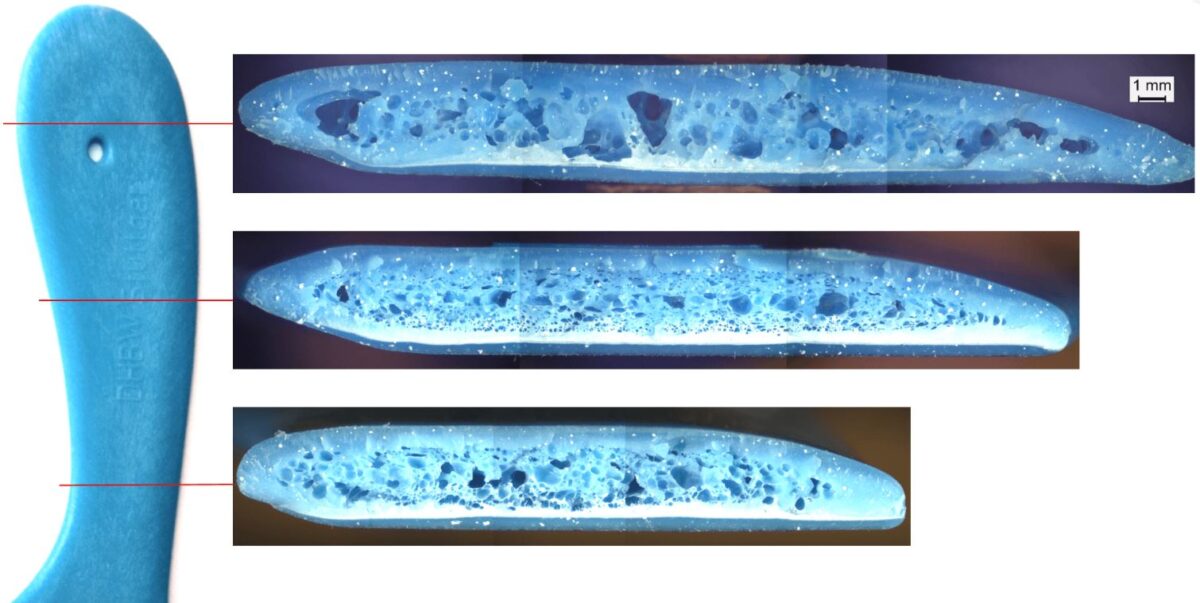

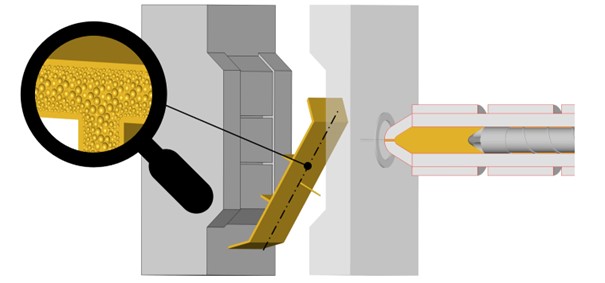

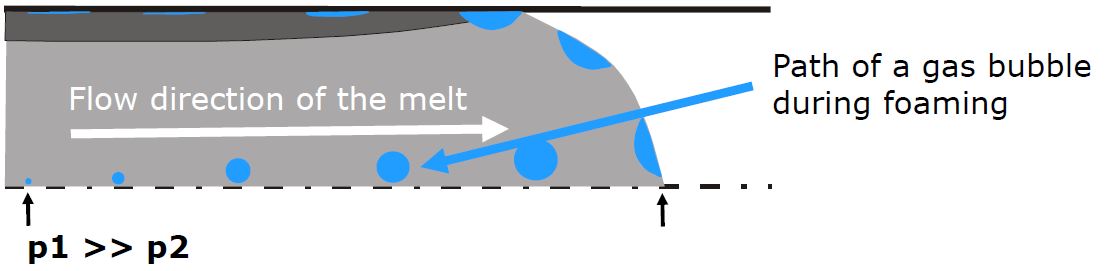

FIM introduces gas (nitrogen or CO2) into molten plastic before injection. As the material fills the mold, the gas expands, forming a microcellular foam structure inside the part. This creates two key benefits: Weight Reduction (10-30%) – The foamed core replaces solid plastic with gas-filled cells. Enhanced Strength-to-Weight Ratio – The solid outer skin ensures durability while the foam core improves stiffness.

Two Primary FIM Methods

| Physical Foaming | Chemical Foaming |

|---|---|

| Uses supercritical gas (N2/CO2) | Uses chemical blowing agents |

| Produces ultra-fine cells (5-50µm) | Larger cell structure (50-500µm) |

| Best for precision parts (e.g., electronics) | Cost-effective for thick parts |

| Example: MuCell technology | Common in structural foam molding |

With the application of foam injection molding technologies, Warpage can be reduced by 40-60%. Courtesy of HeiQ – Heitkamp Kunststofftechnik and MuCell

Key Benefits of Foam Injection Molding

Material Efficiency

5-15% polymer savings per part

Up to 30% weight reduction maintained strength

Production Advantages

30-50% lower clamping force needed

Faster cycle times through improved cooling

Aluminum molds become viable options

Quality Improvements

90% reduction in sink marks

Warpage decreased by 40-60%

More consistent part dimensions

FIM Industry Applications

- Automotive: Door panels, dashboards, and under-hood components (lighter equals better fuel efficiency).

- Electronics: Smartphone housings, laptop bezels (thin walls plus reduced weight).

- Household & Appliances: Refrigerator liners, washing machine bases (less warpage, lower costs)

- Industrial: Pallets, containers, and tool housings (durable yet lightweight)

Overcoming Challenges

While FIM offers tremendous benefits, the technology has faced hurdles that engineers have creatively solved:

Surface Quality

Early foam parts often showed streaking, but modern solutions like variothermal molding and gas counter pressure now produce surfaces rivaling solid injection molding.

Structural Predictability

Advanced simulation tools now accurately predict how foam will behave in complex geometries, allowing designers to optimize part configurations before production.

Solidified edge layer on the cold mould wall. The surface covered with streaks is avoidable through variothermal processes or gas counter pressure. Courtesy of Kunststoff Institute Lüdenscheid.

Material Compatibility

Originally limited to standard polymers, FIM now works with:

Engineering plastics (PBT, PA)

High-temperature resins

Filled composites (up to 40% glass fiber)

Future Trends in Foam Molding

- Nano-Cellular Foams (under 1µm cells for ultra-lightweight parts)

- AI-Optimized Processes – Smart adjustments for perfect foaming

- Sustainable Blowing Agents – Eco-friendly gas alternatives

Foam injection molding is no longer just an alternative—it’s the present instead the future of efficient plastic manufacturing. With benefits like material savings, lighter parts, and reduced defects, FIM is becoming essential for automotive, electronics, and consumer goods industries. As technology advances, expect even thinner, stronger, and more sustainable foam-molded products. Ready to explore foam molding for your next project? The advantages speak for themselves—lighter, cheaper, and better-performing parts are within reach.

To read more: SCHÄUMEN IM SPRITZGIESSVERFAHREN – Kunststoff-Institut Lüdenscheid

If you would like to learn more about core back foam injection molding, attend the SPE course, “Core Back Foam Injection Molding – A Design and Engineering Guide for Lightweighting” on September 2.