EU Launches First Certified Reference Material for Microplastic Analysis

A new certified reference material from the European Commission advances the standardization of microplastic analysis in a water matrix.

In February 2025, the European Commission’s Joint Research Centre (JRC) released the first certified reference material (CRM) for microplastics in water. This PET-based material helps labs compare results, test methods, and monitor the environment. It also gives the plastics industry a new tool for quality control, research, and tracking emissions.

You can also read: Editor’s Letter: Navigating Misinterpretation, Nanoplastics in Bottled Water.

A Technical Challenge in Polymer Metrology

For over a decade, detecting and measuring microplastics accurately in water has been difficult due to the lack of traceable standards. Current methods, such as Fourier Transform Infrared, Raman spectroscopy, and pyrolysis-GC/MS, differ widely in detection limits, selectivity, and sample preparation. Until now, no CRM has been available to evaluate how well these methods perform under consistent conditions.

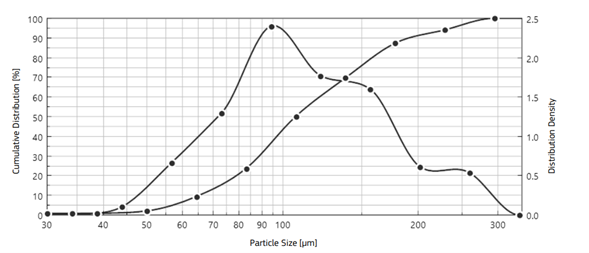

The new JRC EURM‑060 fills this critical gap. It contains PET microplastic particles provided in a format that ensures consistent preparation: a kit including a vial of freeze-dried PET particles embedded in sodium chloride, a bottle of ultrapure water (950 mL), and a bottle of 0.1% Triton X-100 solution (60 mL). The material comes with certified values for both mass concentration and particle number concentration, as well as particle size distribution after reconstitution. Experts used complementary techniques, such as laser diffraction, optical and electron microscopy, and flow imaging, to define these parameters.

Material Design and Properties

The choice of PET is deliberate. This polymer plays a key role in water bottles and packaging; researchers frequently detect it in aquatic environments. To ensure homogeneity and reproducibility, the team produced the reference material using controlled cryogenic milling, followed by wet sieving with ultrasonic treatment.

The certified reference material contains PET microplastic particles, including many smaller than 50 μm. Some particles are even in the 1–20 μm range, which makes them especially challenging for routine analysis. Their small size increases mobility in the environment and potential uptake by organisms. It also requires specialized techniques for sample preparation and filtration in the lab. By including such fine particles, the material helps laboratories test and improve their ability to detect and measure small microplastics reliably.

Volume-based size distributions of particles in the final suspension used for production of EURM-060. Courtesy of JRC.

Implications for Polymer R&D and Process Engineering

This CRM has direct applications in industrial R&D, polymer processing, and quality assurance. Companies developing new polymers or additives can use the CRM to test product behavior under standardized conditions, such as degradation, fragmentation, or shedding into liquids.

For example, developers of fiber-based nonwovens or surface coatings can use the CRM to check how well filtration systems work or to test how much material sheds particles. It also helps manufacturers measure microplastics released during cutting, milling, or pellet handling. This supports benchmarking and controlling emissions.

CRM facilitates quality control practices within analytical laboratories operating under ISO/IEC 17025. It enables control charting, performance verification of new instrumentation, and long-term method development with a fixed reference.

Toward Standardized Microplastics Analytics

The release of this PET-based CRM comes at a critical time, as regulatory agencies and standards bodies move toward formalizing analytical protocols for microplastics in environmental and consumer matrices. Ongoing work by ISO/TC 61 and CEN/TC 444 aims to establish consistent definitions, analytical methods, and reporting formats.

A traceable CRM like EURM‑060 strengthens these efforts by anchoring new standards to a shared measurement framework. Regulators and industry leaders plan to use it to support initiatives such as the European Chemicals Agency’s proposal to restrict intentionally added microplastics. It can also help develop future product certification schemes and environmental performance labels.

Next Steps: Expanding the CRM Portfolio

EURM‑060 is only the beginning. The JRC is currently developing additional reference materials based on other common polymers, including PP, PE, and PS, and plans to incorporate more complex matrices such as sediments and biota. Future CRMs may also address nano-sized plastic particles (<1 μm), which pose even greater analytical challenges.